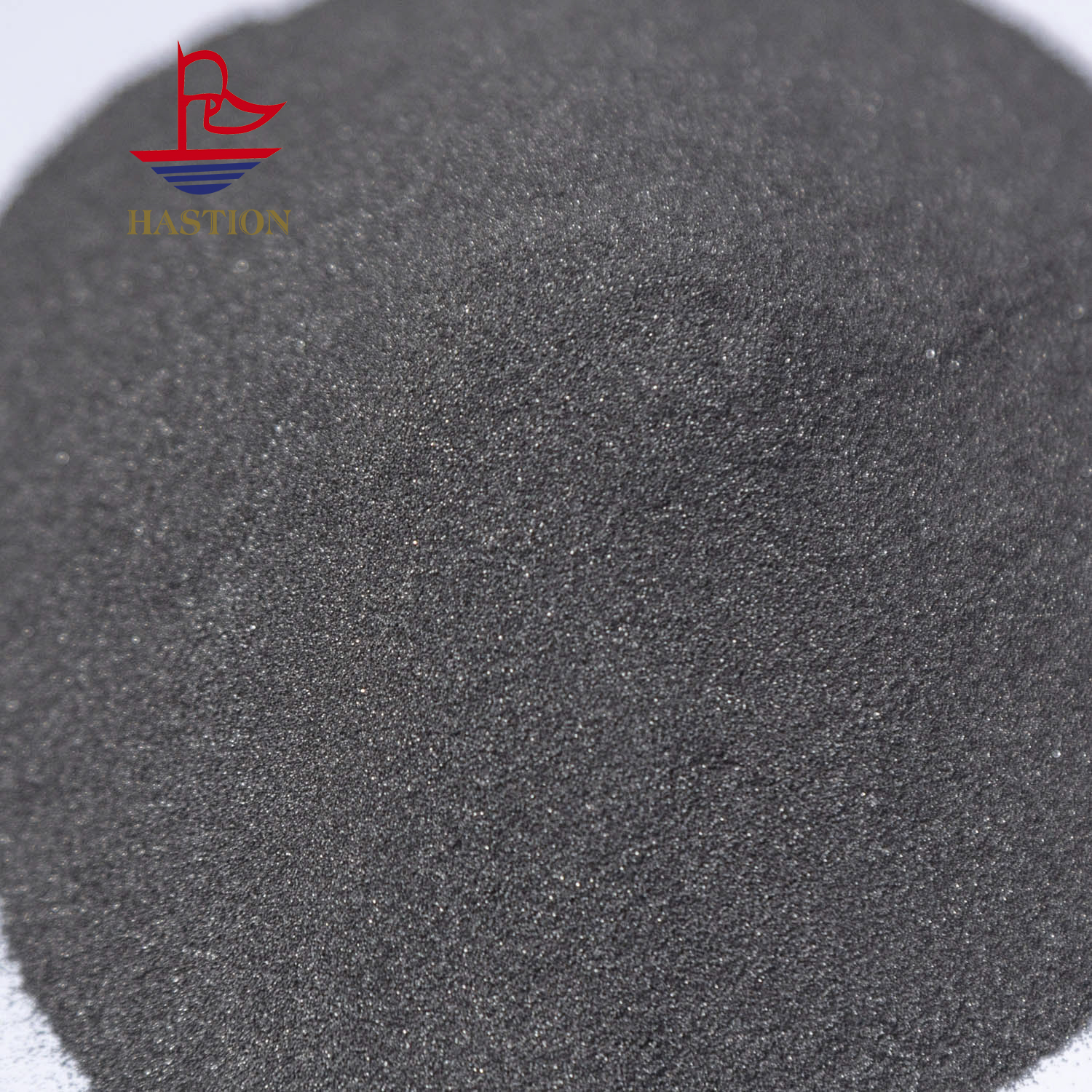

The core material of metal ceramics is titanium carbide powder

Titanium carbide powder has excellent oxidation resistance. It is not prone to oxidation in the air below 600℃, and the oxidation rate at 800℃ is only 0.01mg/(cm²·h), making it suitable for manufacturing high-temperature wear-resistant components. Coating it on the surface of steam turbine blades can resist the erosion and oxidation of high-temperature gas, thereby extending the service life of the blades. The powder has a high grinding efficiency and can be used to make abrasives. When grinding hard alloys, its efficiency is twice that of alumina abrasives. In the processing of optical glass, the grinding tools made of this powder can ensure the high smoothness of the glass surface. The powder has low toxicity and complies with environmental protection standards such as RoHS, making it suitable for use in fields with high safety requirements such as medical devices and the food industry. It has good compatibility with biological tissues. The bone repair materials made from it can promote the growth of bone cells and accelerate wound healing. The powder has good storage stability. When stored in a sealed container, its shelf life can reach more than 5 years without caking or deteriorating.

Other supplier products

|

|

Ultrafine Spherical Chromium Carbide Powder |

Chromium carbide powder is an inorganic compound, the main component is Cr3C2, powder powder Its high hardness, wear resistance, corrosion resist... |

|

|

Chromium carbide powder for automotive brake pads |

This chromium carbide powder is black in color, with a particle size of 5-25μm, a purity of over 99%, and extremely low impurity content. The pa... |

|

|

Steel-bonded hard alloy round bar, TiC hard phase, steel bonding phase |

Compared with conventional high-speed steel bars, carbide titanium round bars enable a 3–5× increase in cutting speed, thereby substant... |

|

|

High-purity titanium carbide rods for mold repair |

Titanium carbide round rods fabricated from cemented carbide exhibit exceptional anti-adhesion properties. When machining sticky materials such as ... |

|

|

Carbide guide rollers for wire and cable production |

Lighter than Tungsten carbide roller by 55%, Lighter than tool steel than 20%, so the guide roller accelerates from standstill to 35,000 rpm, witho... |

All supplier products

Same products