Inconel alloy 3D Printing Prototyping Service

Introduction to Inconel Alloy 3D Printing Prototyping Service

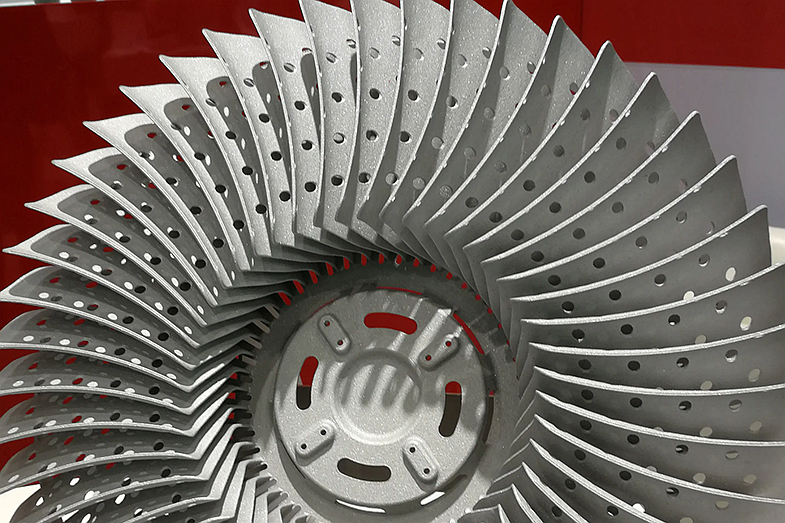

Inconel alloys, a family of high-performance nickel-chromium superalloys, are renowned for their excellent heat resistance, mechanical strength, and oxidation resistance in extreme environments. These materials are commonly used in aerospace, gas turbines, power generation, and chemical processing industries, where components are subjected to high temperatures, pressure, and corrosive conditions. At NewayAero, we offer advanced Inconel Alloy 3D Printing Prototyping Services to help accelerate product development and create highly complex, high-performance parts with unparalleled precision.

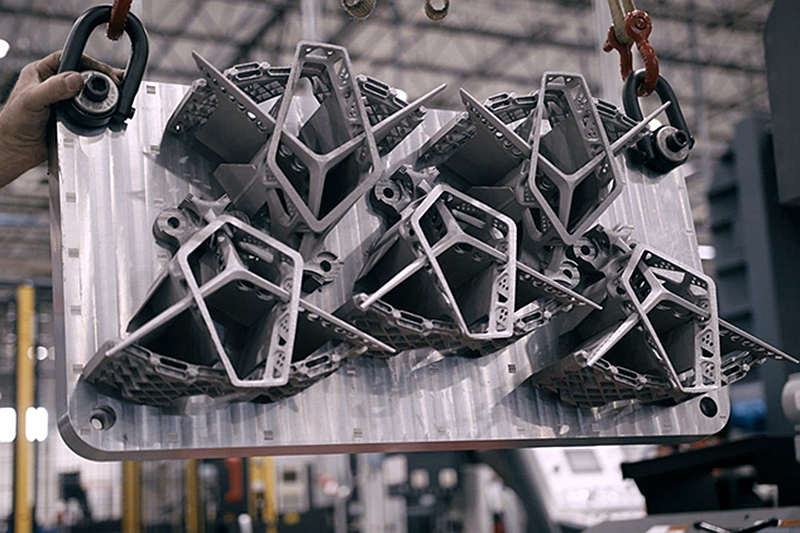

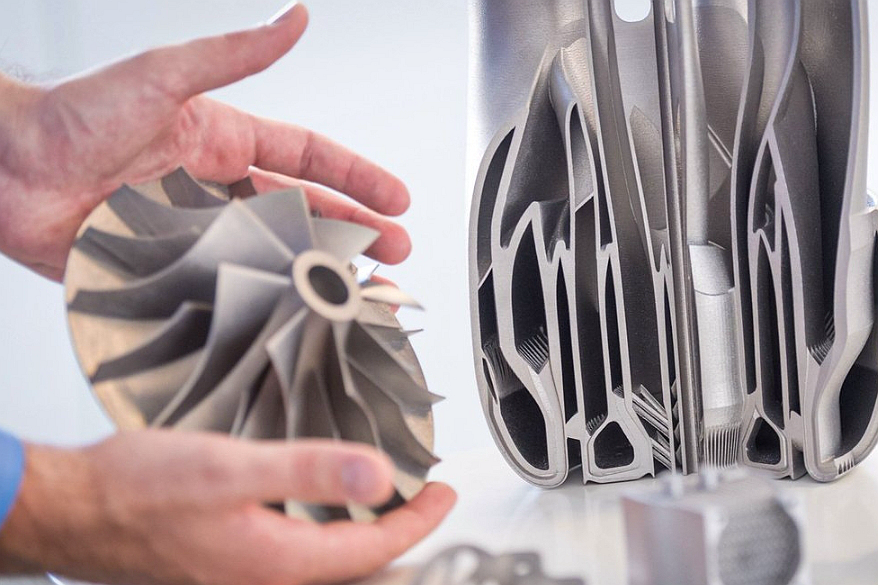

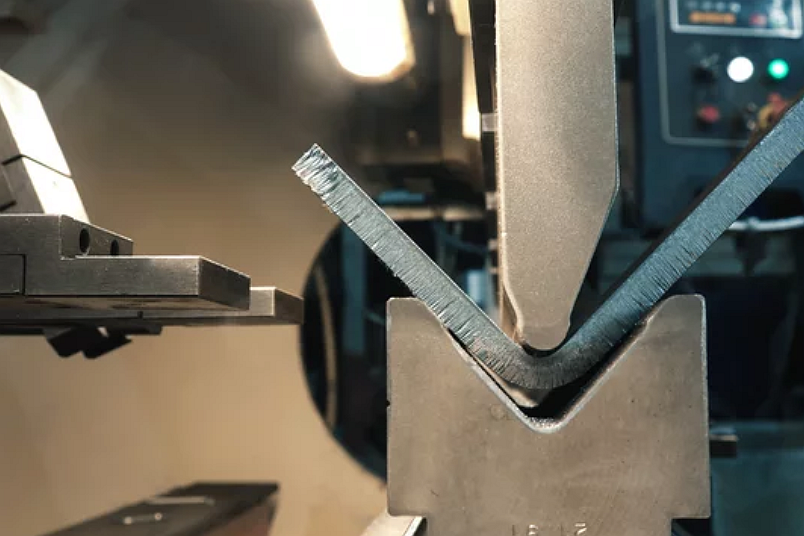

The 3D printing process, often called additive manufacturing, involves the layer-by-layer deposition of metal powder to build a part from a digital 3D model. This method allows for producing parts with complex geometries that would be difficult or impossible to achieve using traditional manufacturing methods such as casting or machining. The process begins by selecting the appropriate Inconel alloy powder, which is then melted by a high-powered laser or electron beam in a controlled environment. As each material layer is melted and solidified, the next layer is added until the part is fully formed.

One of the key benefits of 3D printing with Inconel alloys is the ability to produce intricate, lightweight structures with optimized material usage. This is particularly important in aerospace and turbine applications, where reducing weight without compromising strength is critical. Additionally, 3D printing allows for rapid prototyping, enabling faster design process iteration and reducing lead times. It also eliminates the need for expensive tooling and molds, making it a cost-effective solution for small production runs or custom components.

After printing, the parts undergo post-processing steps such as heat treatment, surface finishing, and stress relief to optimize the material's mechanical properties. These steps ensure that the final part meets the required standards for performance, including high-temperature strength, fatigue resistance, and corrosion resistance.

Common Grades of Inconel Alloys for 3D Printing

Common grades of Inconel alloys used in 3D printing include:

Inconel Alloy Grades

- Inconel 718

- Inconel 625

- Inconel 600

- Inconel 713C

- Inconel X-750

- Inconel 825

For example, Inconel 718 is a popular choice in aerospace for turbine blades and other high-stress components due to its excellent mechanical properties at elevated temperatures. Inconel 625 is known for its exceptional fatigue and thermal-fatigue strength, making it ideal for marine and chemical processing applications. Other grades such as Inconel X-750 and Inconel 600 offer superior resistance to oxidation and are used in applications where components are exposed to extreme heat and corrosive environments.

With NewayAero’s Inconel Alloy 3D Printing Prototyping Services, industries can benefit from rapid, cost-effective prototyping that delivers high-quality, high-performance parts that meet the most stringent standards.

Send product request

Other supplier products

| Custom Precision Cast Parts Manufacturing Service | Our custom precision cast parts manufacturing services are mainly die casting, lost wax casting, sand casting, and gravity casting. According to ... | |

| Titanium Alloy Vacuum Investment Casting Service | Introduction to Titanium Alloy Vacuum Investment Casting Service Titanium alloys are known for their excellent combination of strength, lightweigh... | |

| 3D Printing Prototyping Service | Affordable 3D Printing Services for Rapid Prototyping:Need a quick turnaround on your product prototype? Our 3D printing services offer affordabl... | |

| CMSX Series Single Crystal Casting Service | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanced single crystal superalloy materials designed fo... | |

| Metal Bending Service | Efficient and Cost-effective Metal Bending Services! Need metal bending done right and on time? Look no further. Our experienced team and advance... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |