Single Crystal Alloy Vacuum Investment Casting Services

Introduction to Single Crystal Alloy Vacuum Investment Casting Services

Single crystal alloys are a critical class of materials used in advanced aerospace and power generation applications. These alloys are known for their superior mechanical properties, especially at high temperatures, making them ideal for demanding components such as turbine blades and nozzles in jet engines and gas turbines. Single crystal alloys eliminate grain boundaries, which can act as points of weakness, resulting in improved creep resistance, fatigue resistance, and overall strength. At NewayAero, our Single Crystal Alloy Vacuum Investment Casting Services utilize state-of-the-art technology to produce precision-engineered components that meet the most stringent industry standards.

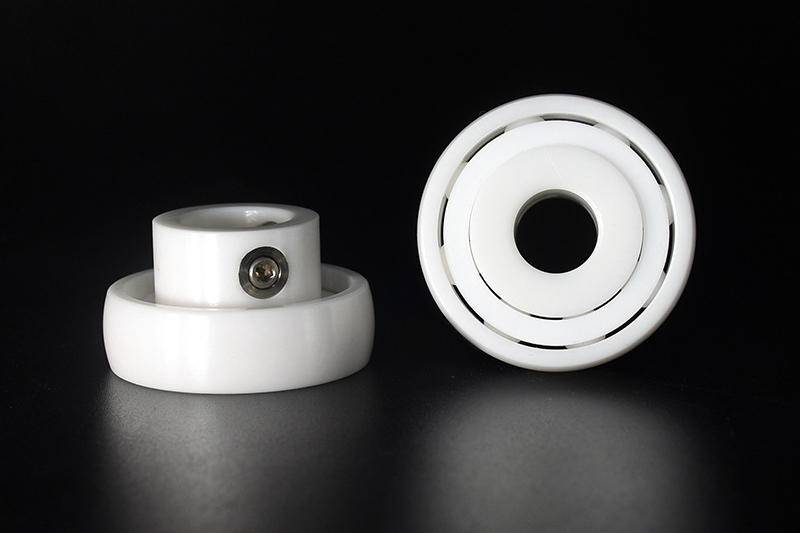

The vacuum investment casting process is ideal for manufacturing high-precision parts from single crystal alloys. The process begins with the creation of a wax pattern, which is an exact replica of the final component. The pattern is coated with a fine ceramic shell through a multi-step dipping process, followed by drying and hardening. Once the shell is prepared, the wax is removed, and the mold is heated to remove any remaining residues, leaving behind a hollow ceramic mold. The mold is then placed in a vacuum chamber, where molten single crystal alloy is poured into the mold under carefully controlled conditions. The vacuum environment ensures that the casting is free from contaminants and minimizes the formation of defects, resulting in high-quality, uniform parts.

One of the key advantages of vacuum investment casting for single crystal alloys is its ability to produce complex geometries with high precision and excellent surface finish. This is particularly important for components like turbine blades, which require intricate shapes and high tolerance levels. After casting, the parts undergo a series of heat treatments to optimize their mechanical properties, including solution annealing and aging processes. These steps enhance the strength, thermal stability, and fatigue resistance of the alloys, making them suitable for use in extreme high-temperature environments. By utilizing vacuum casting techniques, NewayAero ensures the production of durable and reliable components that meet the exacting standards of the aerospace and power generation industries.

Common Single Crystal Alloys for Vacuum Investment Casting

Common single crystal alloys used in the vacuum investment casting process include:

Single Crystal Alloy Grades

-

CMSX-10

CMSX-11

CMSX-2

CMSX-2 Alloy

CMSX-3

CMSX-4

CMSX-486

CMSX-6

CMSX-7

CMSX-8

DD6

EPM-102

PWA 1480

PWA 1484

Rene N5

Rene N6

RR3000

SC180

SRR 99

TMS-138

TMS-162

TMS-196

TMS-238

TMS-75

For example, CMSX-10 is one of the most widely used single crystal alloys in turbine blade manufacturing due to its excellent high-temperature strength and oxidation resistance. CMSX-4 is known for its superior creep resistance, making it ideal for components that operate in extreme thermal conditions. Other alloys like PWA 1480 and TMS-75 are chosen for their outstanding mechanical properties and high-temperature stability, ensuring the longevity and reliability of critical aerospace and power generation components.

At NewayAero, our Single Crystal Alloy Vacuum Investment Casting Services are designed to produce parts that meet the rigorous demands of the aerospace, power generation, and defense industries, offering unmatched performance in the most challenging environments.

Send product request

Other supplier products

| Ceramic Injection Molding(CIM) for Custom Ceramic Parts | Excellent on-demand ceramic injection molding service for manufacturing custom CIM parts. Get your custom CIM components in exceptional quality a... | |

| Aluminum Laser Cutting Service | Trust our expert team to deliver high-quality, cost-effective custom aluminum laser cutting solutions for your business needs. Sheet Met... | |

| CMSX Series Single Crystal Casting Service | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanced single crystal superalloy materials designed fo... | |

| Casting Superalloys (High temperature alloys) Vacuum Investment Casting | At , we specialize in high-performance casting services for superalloys, focusing on for the most demanding applications. Our Vacuum Investment Ca... | |

| Rene Alloys Vacuum Investment Casting Service | Introduction to Rene Alloys Vacuum Investment Casting Service Rene alloys are a series of high-performance nickel-based superalloys that are engin... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |