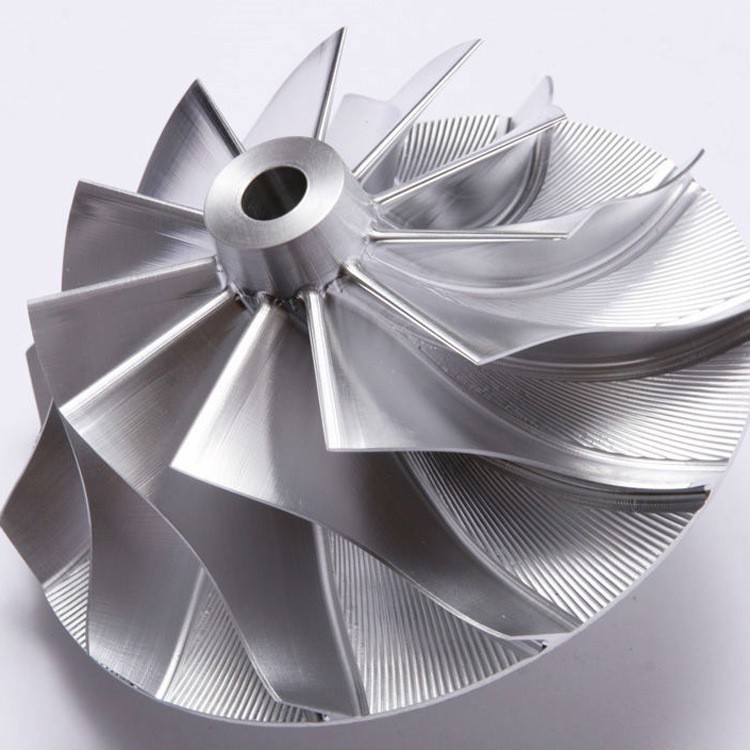

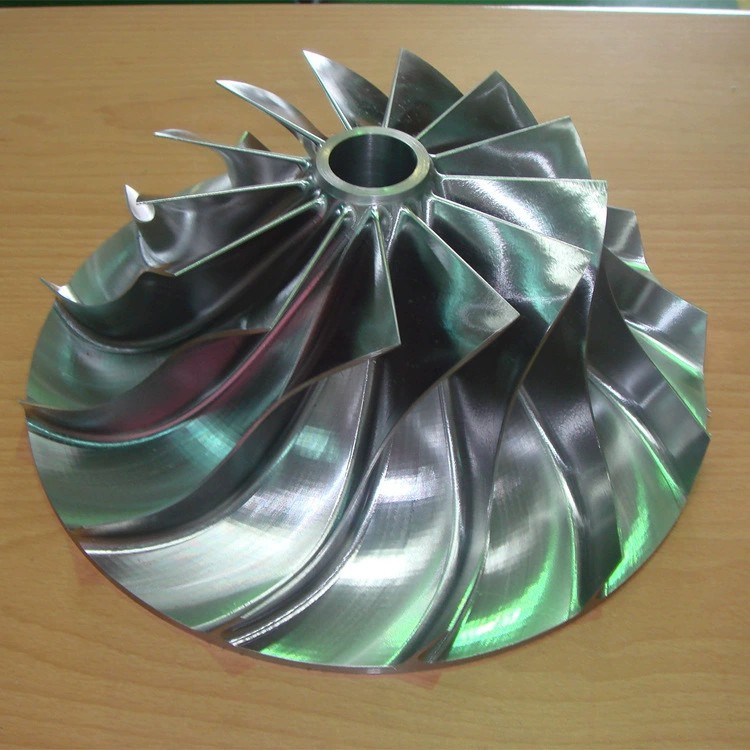

Nimonic Alloy Equiaxed Crystal Casting Service

Introduction to Nimonic Alloy Equiaxed Crystal Casting Service

Nimonic alloys are a family of high-performance, nickel-based superalloys known for their exceptional strength and resistance to oxidation and corrosion at high temperatures. These properties make Nimonic alloys the material of choice for critical applications in aerospace, power generation, and gas turbines, where components are subjected to extreme thermal and mechanical stresses. At NewayAero, ourNimonic Alloy Equiaxed Crystal Casting Serviceprovides precision-cast components that deliver the reliability and performance required for such high-demand applications.

Equiaxed crystal castingis a specialized manufacturing process designed to produce parts with uniform, fine-grained structures, which is crucial for ensuring consistent mechanical properties across the entire component. In this process, molten Nimonic alloy is poured into a mold, and as it cools, the grain structure forms in a way that results in grains of nearly equal size in all directions. This equiaxed structure minimizes directional weaknesses and improves the material’s strength, toughness, and fatigue resistance.

The casting process begins with preparing a mold, which can be created using sand casting, investment casting, or other precision casting techniques. The molten Nimonic alloy is poured into the mold, allowing it to cool and solidify under controlled conditions. During the cooling process, the nucleation sites are managed to promote the growth of equiaxed crystals. Once the part is solidified, it undergoes post-casting heat treatment to optimize its mechanical properties and enhance its performance in high-temperature and corrosive environments.Post-casting heat treatmentis crucial for improving the strength and durability of Nimonic alloy components, ensuring they meet the rigorous demands of industries such asaerospaceandpower generation.

Through our precision casting and comprehensive post-processing services, NewayAero delivers Nimonic alloy components with superior performance, high fatigue resistance, and exceptional thermal stability, making them ideal for the most demanding industrial applications.

Nimonic Alloys for Equiaxed Crystal Casting

Nimonic alloysare typically selected for equiaxed crystal casting based on specific application requirements, such as high-temperature strength, oxidation resistance, and fatigue resistance. These alloys are highly regarded in industries that require components to perform under extreme conditions. Some of the most commonly used grades of Nimonic alloys for equiaxed crystal casting include:

Nimonic Grades for Equiaxed Crystal Casting

-

Nimonic 105

Nimonic 115

Nimonic 263

Nimonic 75

Nimonic 80A

Nimonic 81

Nimonic 86

Nimonic 90

Nimonic 901

Nimonic PE11

Nimonic PE16

For example,Nimonic 75offers excellent oxidation resistance at high temperatures, making it ideal for turbine blades and other components in gas turbines.Nimonic 263is widely used for its high strength and creep resistance at elevated temperatures.Nimonic PE11is specifically designed for advanced applications that require outstanding fatigue strength and high-temperature performance.

AtNewayAero, we use the latest technologies and precise control methods in ourNimonic alloy equiaxed crystal casting serviceto deliver components with the highest quality, reliability, and performance in demanding industries.

Send product request

Other supplier products

| Titanium Alloy CNC Machining Service | Introduction to Titanium Alloy CNC Machining Service Titanium alloys are known for their exceptional strength-to-weight ratio, outstanding corrosi... | |

| Inconel alloy Equiaxed Crystal casting Service | Inconel Alloy Equiaxed Crystal Casting Service: Introduction Inconel alloys, renowned for their exceptional strength, corrosion resistance, and ab... | |

| Aluminum Laser Cutting Service | Trust our expert team to deliver high-quality, cost-effective custom aluminum laser cutting solutions for your business needs. Sheet Met... | |

| Plastic Injection Molding Companies for Plastic Molding | Reliable custom plastic injection molding companies for your OEM plastic molding parts. Start your project today to get exceptional custom-inject... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components Inconel alloypowder metallurgy(PM) tu... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |