Titanium Alloy CNC Machining Service

Introduction to Titanium Alloy CNC Machining Service

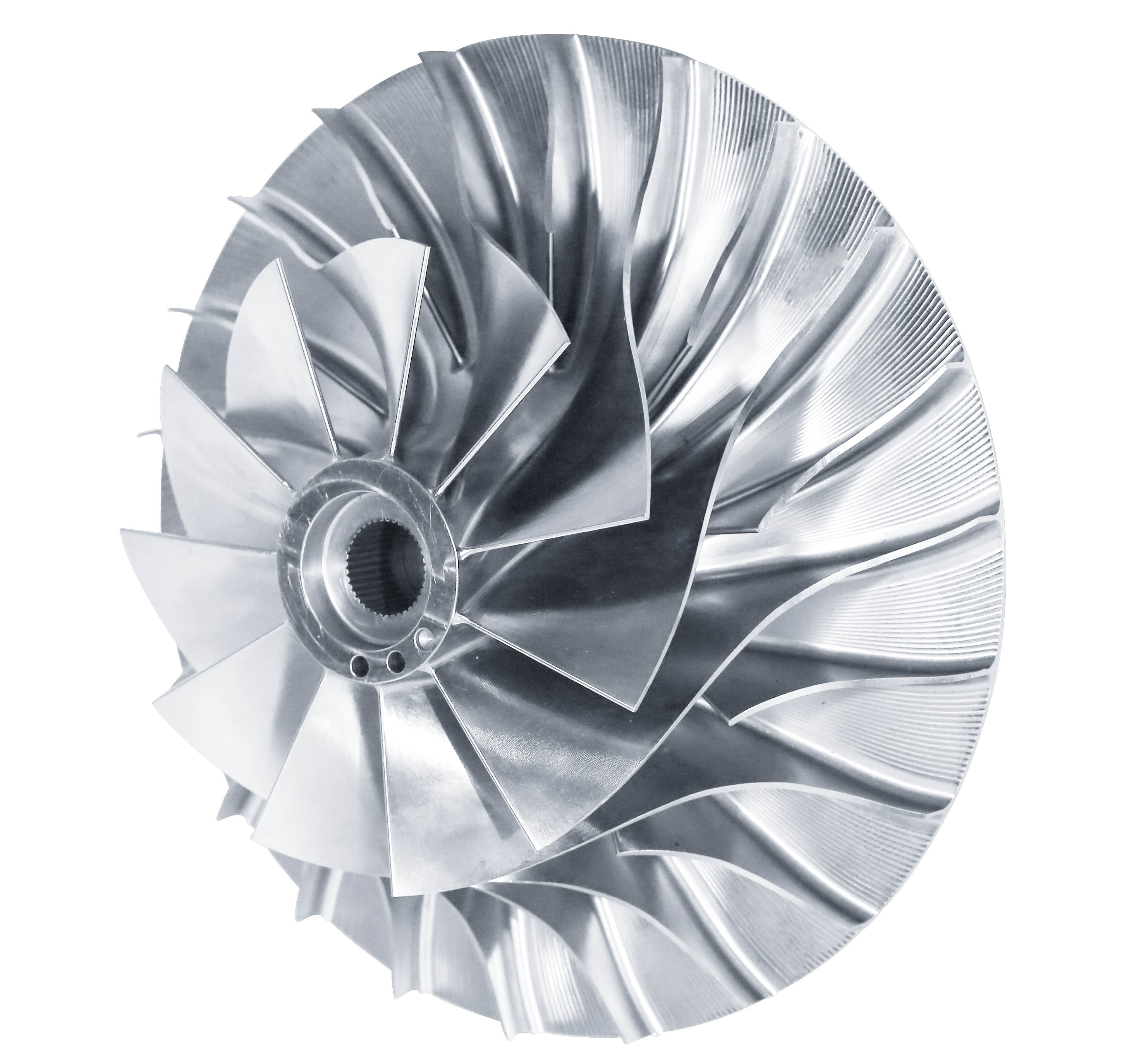

Titanium alloys are known for their exceptional strength-to-weight ratio, outstanding corrosion resistance, and high performance in extreme temperatures. These properties make them the material of choice for high-demand applications in aerospace, automotive, medical, and marine industries. At NewayAero, our Titanium Alloy CNC Machining Service leverages advanced machining technologies to provide precision-engineered titanium components that meet the rigorous demands of these industries.

CNC (Computer Numerical Control) machining is a versatile and efficient manufacturing process that utilizes computer-controlled machines to precisely cut, shape, and finish materials based on a digital design model. In titanium alloy CNC machining, titanium alloy billets or blocks are loaded into CNC machines, where they are subjected to a series of cutting operations. These include milling, turning, drilling, and grinding, all of which are performed with high precision to produce parts with complex geometries and tight tolerances. CNC machining offers unparalleled accuracy and repeatability, making it ideal for producing titanium alloy components that require tight specifications.

The primary advantage of CNC machining is its ability to create intricate shapes and designs while maintaining high material integrity. This is particularly important when machining titanium alloys, known for their hardness, low machinability, and tendency to generate high heat during processing. Specialized tools and techniques, such as high-speed cutting and optimized coolant systems, are used to prevent overheating and ensure efficient material removal while preserving the material's mechanical properties. Techniques such as precision casting are critical in the production of titanium alloy components that require tight tolerances and precise dimensions.

After the machining process, titanium parts often undergo post-processing steps such as heat treatment, surface finishing, and deburring to improve their surface quality and mechanical properties. These post-machining processes help to enhance characteristics like strength, fatigue resistance, and wear resistance, ensuring the final product meets the exact requirements of its aerospace application. By combining high precision machining and advanced post-processing, we ensure that each titanium alloy component meets the exacting standards required in aerospace, automotive, and marine industries.

Common Grades of Titanium Alloys for CNC Machining

Common grades of titanium alloys used in CNC machining include:

- Ti-6Al-4V (Grade 5)

- Ti-6Al-4V ELI (Extra Low Interstitial)

- Ti-3Al-2.5Sn

- Ti-5Al-2.5Sn

- Ti-10V-2Fe-3Al

- Ti-13V-11Cr-3Al

For example, Ti-6Al-4V (Grade 5) is the most widely used titanium alloy in aerospace and medical industries due to its excellent strength, weight, and corrosion resistance balance. Ti-6Al-4V ELI is specifically designed for medical implants, offering superior purity and biocompatibility. Other grades such as Ti-3Al-2.5Sn and Ti-5Al-2.5Sn are used in aerospace applications for their superior fatigue strength and resistance to high temperatures.

NewayAero’s Titanium Alloy CNC Machining Services combine cutting-edge CNC machining technologies with the highest quality titanium alloys to produce precise, high-performance parts tailored to meet the needs of a wide range of industries.

Send product request

Other supplier products

| Rene Alloys Vacuum Investment Casting Service | Introduction to Rene Alloys Vacuum Investment Casting Service Rene alloys are a series of high-performance nickel-based superalloys that are engin... | |

| Titanium Alloy CNC Machining Service | Introduction to Titanium Alloy CNC Machining Service Titanium alloys are known for their exceptional strength-to-weight ratio, outstanding corrosi... | |

| Nimonic Alloy Equiaxed Crystal Casting Service | Introduction to Nimonic Alloy Equiaxed Crystal Casting Service Nimonic alloys are a family of high-performance, nickel-based superalloys known for... | |

| Precision Manufacturing of High-Temperature Alloy Components | Company Introduction: NewayAero – Precision Manufacturing of High-Temperature Alloy Components NewayAero is a leading provider of high-quali... | |

| Stellite Alloy Superalloy Precision Forging Service | Introduction to Stellite Alloy Superalloy Precision Forging Service Stellite alloys are a group of cobalt-based superalloys that are known for the... |

Same products

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Cast iron service | Seller: SHANXI HELIOS CASTING AND FORGING INDUSTRIAL CO., LTD. | Helios own a variety of casting processes, including clay sand horizontal automatic molding line,... | |

| Inconel Alloy Directional Casting Service: Precision for High-Performance Applications | Seller: Neway Precision Works Ltd | Inconel Alloy Directional Casting Service: Precision for High-Performance Applications Inconel a... | |

| Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance Components | Seller: Neway Precision Works Ltd | Inconel Alloy Powder Metallurgy Turbine Disc Service: Advanced Manufacturing for High-Performance... | |

| CMSX Series Single Crystal Casting Service | Seller: Neway Precision Works Ltd | Introduction to CMSX Series Single Crystal Casting Service The CMSX Series is a family of advanc... |