refractory silica brick for industry furnace

Product Introduction of Silica Brick

The material of silica brick is quartzite as raw material, adding a small amount of mineralizer. Sintered at high temperature, its mineral composition is composed of tridymite, cristobalite and vitreous formed at high temperature, and its AiO2 content is above 93%. Among the well-fired silica bricks, the content of tridymite is the highest, accounting for 50% to 80%; cristobalite takes the second place, accounting for only 10% to 30%; while the content of quartz and glass phase fluctuates between 5% and 15%.

The material of silica bricks is made of quartzite as raw material, adding a small amount of mineralizer, and firing at high temperature. Its mineral composition is tridymite, cristobalite and glassy formed at high temperature. Its SiO2 content is 93 %above.

Silica brick is an acid refractory material, which has strong resistance to acid slag erosion, but when it is strongly eroded by alkaline slag, it is easily damaged by oxides such as Al2O3, and has good resistance to oxides such as iCaO, FeO, and Fe2O3.

The biggest disadvantage of the load is low thermal shock stability and low refractoriness, generally between 1690-1730°C, which limits its application range to a certain extent.

Silica Bricks - Physical Properties

Acid and alkali resistance

Silica brick is an acidic refractory material, which has strong resistance to acidic slag erosion, but when it is strongly eroded by alkaline slag, it is easily damaged by oxides such as Al2O3, and has good resistance to oxides such as CaO, FeO, and Fe2O3.

expansion

The thermal conductivity of silica bricks increases with the increase of working temperature, and there is no residual shrinkage. During the oven process, the volume of silica bricks increases with the increase of temperature. During the baking process, the maximum expansion of silica bricks occurs between 100 and 300 °C, and the expansion before 300 °C is about 70% to 75% of the total expansion. The reason is that SiO2 has four crystal transformation points of 117°C, 163°C, 180~270°C and 573°C during the oven process, among which the volume expansion caused by cristobalite is the largest between 180~270°C.

Load deflection temperature

High load deformation temperature is the advantage of silica bricks, which is close to the melting point of tridymite and cristobalite, which is about 1640~1680°C.

thermal stability

The biggest disadvantage of silica bricks is low thermal shock stability and low refractoriness, generally between 1690 and 1730 °C, which limits its application range to a certain extent. The key to determine the thermal stability of silica bricks is density, and the density is one of the important signs to determine its quartz transformation. The smaller the density of silica bricks, the more complete the lime conversion, and the smaller the residual expansion during the oven process.

Silica brick - Precautions for use

When the working temperature is lower than 600~700°C, the volume of silica bricks changes greatly, the performance of resistance to rapid cooling and rapid heating is poor, and the thermal stability is not good. If the coke oven works at this temperature for a long time, the masonry will be easily cracked and damaged.

Performance Physical properties of coke oven silica bricks: (1) High softening temperature under load. Coke oven silica bricks can withstand the dynamic load of the coal loading car on the furnace roof at high temperature, and can be used for a long time without deformation; (2) High thermal conductivity. Coke is smelted from coking coal in the carbonization chamber by conduction heating on the wall of the combustion chamber, so the silica bricks used to build the combustion chamber wall should have higher thermal conductivity. In the temperature range of the coke oven combustion chamber, the thermal conductivity of silica bricks is higher than that of clay bricks and high alumina bricks. The thermal conductivity of dense coke oven silica bricks can be increased by 10% to 20% compared with ordinary coke oven silica bricks; (3) It has good thermal shock resistance at high temperatures. Due to the periodic coal charging and coke discharge of the coke oven, the temperature of the silica bricks on both sides of the combustion chamber wall changes drastically. The temperature fluctuation range of normal operation will not cause serious cracks and peeling of silica bricks, because coke oven silica bricks have good thermal shock resistance above 600°C; (4) The volume is stable at high temperature. In silica bricks with good crystal transformation, the residual quartz is not more than 1%, and the expansion during heating is concentrated before 600C, and then the expansion slows down significantly. When the coke oven is in normal operation, the temperature will not drop below 600°C, and the change of the masonry will not be large, and the stability and tightness of the masonry can be maintained for a long time.

Contact:

Marina Ma

Tel:whatsapp/

Other supplier products

All supplier products

Same products

|

|

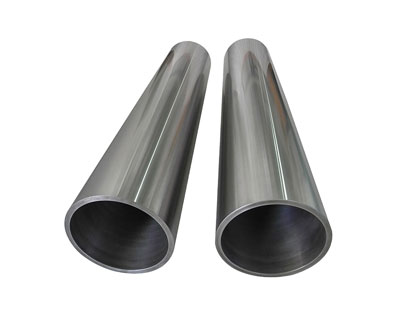

Molybdenum Tube |

Seller: Beijing Huasheng Metal Materials Co., Ltd |

Molybdenum tubehas high melting point, high strength, good thermal conductivity, high temperature... |

|

|

Ferro Tungsten |

Seller: Beijing Huasheng Metal Materials Co., Ltd |

HSG METAL, as one of ferro tungsten suppliers, provides ferro tungsten for sale.

Ferrotungsten... |

|

|

Ferro Niobium |

Seller: Beijing Huasheng Metal Materials Co., Ltd |

Ferroniobium an iron alloy with niobium and iron as its principal components. It also contains im... |

|

|

Ferro Molybdenum |

Seller: Beijing Huasheng Metal Materials Co., Ltd |

Ferro molybdenum is a ferroalloy composed of molybdenum and iron, generally containing 50-60% mol... |

|

|

Ferro Alloy |

Seller: Beijing Huasheng Metal Materials Co., Ltd |

Ferroalloy is a general term for alloys composed of iron and silicon, manganese, chromium, titani... |