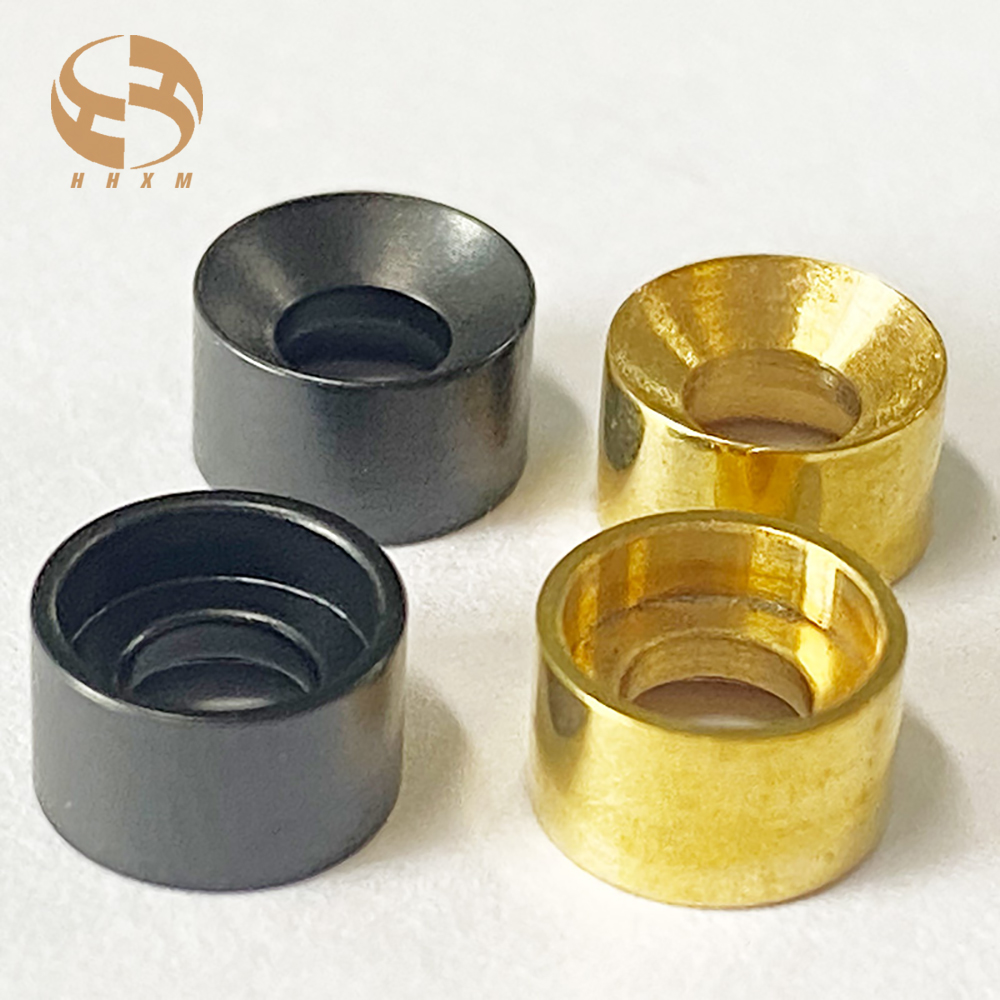

Precision metal deep drawing parts

- Ironingin multi-stationtransfer mold

Through multi-station transfer mold, we produce ironingparts of various non-ferrous metal materials with uniform wall thickness and bright surface. It is more suitable for small batch customizationbecause of theconvenience formoldsreplacement.

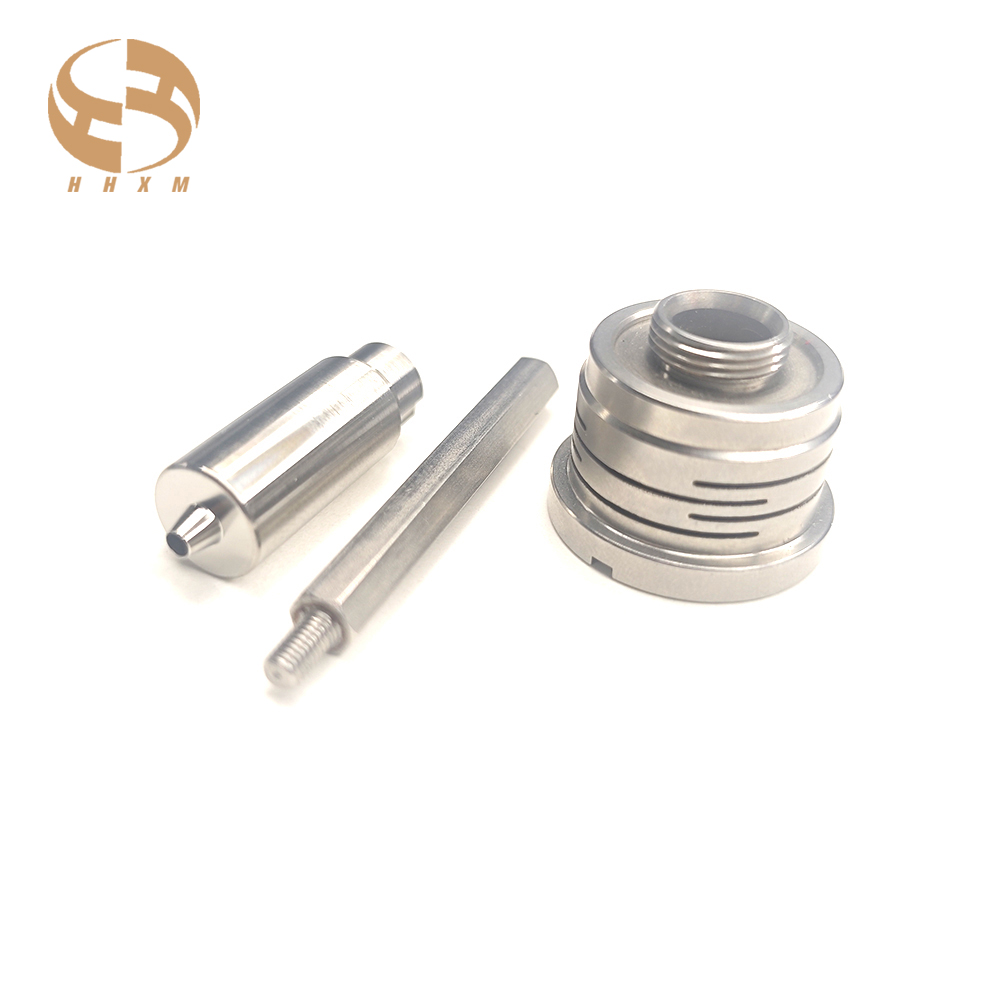

- Deep drawingin high precision progressive die

We use progressive die tofinish deep drawing, punching, rotary cutting, tapping, side punching, necking, flaring, and blanking in onemold.

Processing range:

- The minimum wall thickness of finished product: 0.08mm

Send product request

Other supplier products

| Plastic injection molding parts | Precision injection molding Double-shotmolding,tricolor injection moldingand overmolding—All kinds of precision plastic partscan be manufactu... | |

| Stainless steel stamping parts | We use progressive tools to do the stamping work,high volumes and precision manufacturing are its characteristics. We work withstainless steel, iro... | |

| Precision plastic injection molding parts | We haverealized full automation of material loading and assemblyin injection molding process. Various of metal insert injection moldingcan be manuf... | |

| Precision metal stamping parts | We use progressive tools to do the stamping work,high volumes and precision manufacturing are its characteristics. We work withstainless steel, ir... | |

| Precision metal deep drawing parts | Ironingin multi-stationtransfer mold Through multi-station transfer mold, we produce ironingparts of various non-ferrous metal materials with uni... |

Same products

| CNC Turn-Mill Copper Alloy Components | Seller: Dongguan Huahang Xinma Hardware Co., Ltd. | Turn-mill copper alloy parts with high dimensional consistency for connectors and electrical comp... | |

| Stainless Steel Mounting Brackets | Seller: Dongguan Huahang Xinma Hardware Co., Ltd. | Precision stainless steel brackets for sensors and automation systems. | |

| Alloy Steel Structural Machined Parts | Seller: Dongguan Huahang Xinma Hardware Co., Ltd. | High-strength alloy steel components for heavy-duty machinery and industrial equipment. | |

| Titanium Alloy Precision Screws | Seller: Dongguan Huahang Xinma Hardware Co., Ltd. | Lightweight, high-strength titanium screws for medical, sports, and aerospace applications. | |

| Custom Copper Connectors & Rivets | Seller: Dongguan Huahang Xinma Hardware Co., Ltd. | High-conductivity copper connectors and rivets for electronic and electrical applications. |