Film-forming Agent

A filmforming agentis a substance that forms a continuous, protective layer on a surface. This layer can be used for various purposes, such as providing protection, enhancing appearance, or improving functionality.

FILM-FORMING AGENT FOR SALE

Alcohol Ester-12

Alcohol Ester-16

MAIN FUNCTIONS OF FILM-FORMING AGENTS

1

Surface protection: Natural film forming agentscan protect surfaces from damage, wear, and tear, or environmental exposure. For example, they can be used to protect wood, metal, or plastic surfaces from moisture, UV radiation, or other environmental factors.c

2

Aesthetics enhancement: Film-forming agents can improve the appearance of a surface by adding gloss, color, or texture. For example, these additives for paints and coatings can be used to add a glossy or matte finish to a surface or to enhance the color and texture of paint or coating systems.

3

Functionality improvement: Film-forming agents can improve the performance of a surface by adding functional properties. For example, they can be used to improve the water resistance, slip resistance, or electrical conductivity of a surface.

4

Durability: Film-forming agents such as alcohol ester 12 can improve the durability of a surface, making it resistant to fading, chipping, or peeling.

FILM FORMING AGENT FEATURES

Ⅰ

Adhesion: Film-forming agents possess good adhesion properties, allowing them to adhere firmly to the surface they are applied to. This ensures that the film remains intact and does not easily peel off or detach.

Cohesion: Film-forming agents have cohesive properties, meaning they can bind to themselves, forming a continuous and uniform film. This cohesive nature ensures the film is structurally stable and resistant to cracking or breaking.

Film Transparency: Many film-forming agents are transparent or have the ability to form transparent films. This is particularly important in applications where the underlying surface or substrate needs to be visible or aesthetically pleasing.

Solubility: Film-forming agents, as industrial bulk and fine chemicals, are often soluble in specific solvents or dispersible in water, allowing for easy application and uniform distribution on the surface. Solubility properties may vary depending on the specific film-forming agent used.

Drying Time: Film-forming agents typically have a suitable drying or curing time, allowing the film to form and set within a desired timeframe. The drying time can be adjusted based on the specific application requirements.

Mechanical Strength: Film-forming agents can provide mechanical strength to the film, making it resistant to abrasion, scratching, or other physical stresses. This feature ensures the longevity and durability of the film.

Barrier Properties: Film-forming agents made by most fine chemical suppliers can create a protective barrier on the applied surface, shielding it from external factors such as moisture, chemicals, UV radiation, or pollutants. This barrier function helps to preserve the integrity of the underlying material.

Flexibility: Some natural film-forming agents exhibit flexibility, allowing the film to bend or stretch without cracking or breaking. This flexibility is particularly important in applications where the film needs to adapt to substrate movement or deformation.

Compatibility: Film-forming agents should be compatible with other ingredients or additives present in the formulation, ensuring stability and homogeneity of the film. Compatibility considerations include solubility, dispersibility, and chemical interactions with other components.

Environmental Considerations: Increasingly, there is a demand for film-forming agents that are environmentally friendly and sustainable. This includes considerations such as low VOC content, biodegradability, and reduced environmental impact.

FILM FORMING AGENT APPLICATIONS

①

Coatings and Paints: Film-forming agents are used in the formulation of coatings and paints to create a protective and decorative film on surfaces. They provide adhesion, durability, and weather resistance to the coating, enhancing its performance and appearance. Film-forming agents are utilized in applications such as architectural coatings, automotive coatings, industrial coatings, and wood finishes.

Food and Beverage Industry: Film-forming agents find applications in the food and beverage industry for edible coatings and films. They are used to enhance shelf life, prevent moisture loss, maintain freshness, and provide a protective barrier to food products. Film-forming agents in this context may include edible polymers or natural substances like proteins and lipids.

②

Packaging Materials: Film-forming agents are employed in the production of packaging materials such as films, laminates, and coatings. They improve the mechanical strength, moisture resistance, and barrier properties of packaging materials, extending the shelf life of packaged products and protecting them from external factors such as oxygen, light, and moisture.

Textiles and Fibers: Film-forming agents are utilized in textile and fiber applications to provide water repellency, stain resistance, or flame resistance. They create a protective film on the fabric surface, enhancing its performance and durability. Film-forming agents can be applied through various methods such as padding, spraying, or coating.

Send product request

Other supplier products

| Acetonitrile Cas 75-05-8 Wholesale | Acetonitrile Cas 75 05 8Wholesale Acetonitrileis an organic chemical compound with the chemical formula CH3CN. It is a colorless liquid that is us... | |

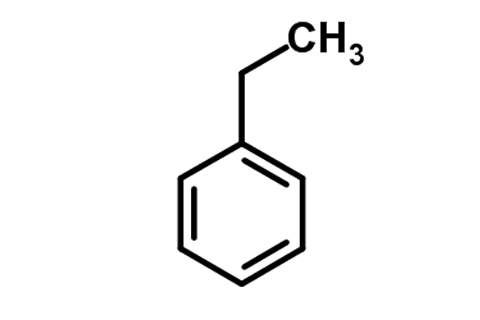

| Aromatic Hydrocarbons | Aromatic hydrocarbons are the collective name for benzene and its carbon and hydrogen-only derivatives, which are hydrocarbon compounds with one or... | |

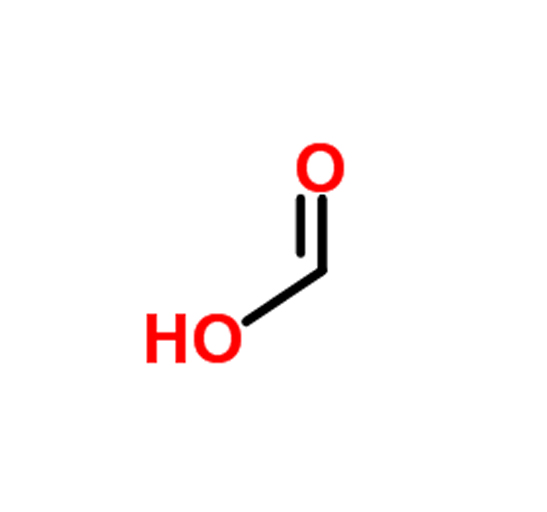

| Formic Acid Cas 64-18-6 Wholesale | Formic Acid Cas 64-18-6 Wholesale Formic Acid China(HCOOH) is a colorless, volatile liquid that is the simplest carboxylic acid. It is naturally p... | |

| Fine Chemicals | Fine chemical productsare specialty chemical products that are manufactured in small quantities and have a high level of purity. They are used as i... | |

| Film-forming Agent | A filmforming agentis a substance that forms a continuous, protective layer on a surface. This layer can be used for various purposes, such as prov... |

Same products

| Glitter Heat Transfer Vinyl | Seller: JIANGYIN QIANTAI NEW MATERIAL TECHNOLOGY CO.,LTD. | Glitter heat transfer vinyl is made by glitter flakes with sparkle effect. Wide application in fa... | |

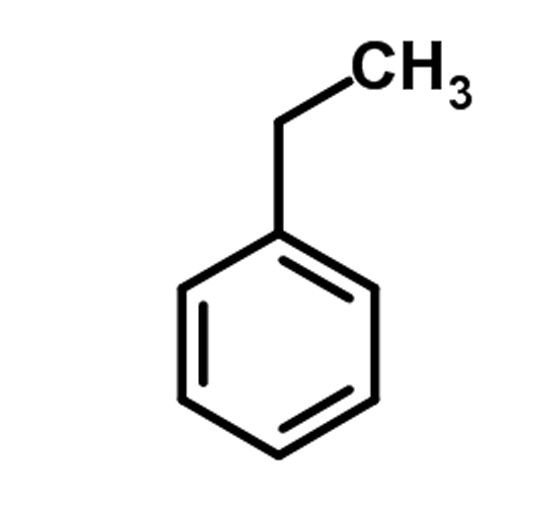

| Ethylbenzene Cas 100-41-4 Wholesale | Seller: SHANGHAI TOPFINE CHEMICAL CO., LTD | A colorless transparent liquid with an aromatic odor. As one of the common aromatic hydrocarbons... | |

| Film-forming Agent | Seller: SHANGHAI TOPFINE CHEMICAL CO., LTD | A filmforming agentis a substance that forms a continuous, protective layer on a surface. This la... | |

| Different designs of paper box sleeve | Seller: XIAMEN RISING FORTUNE IMP&EXP CO.LTD | paper sleeve is used for packing box, bowl and cup etc. There are different designs which can be ... |