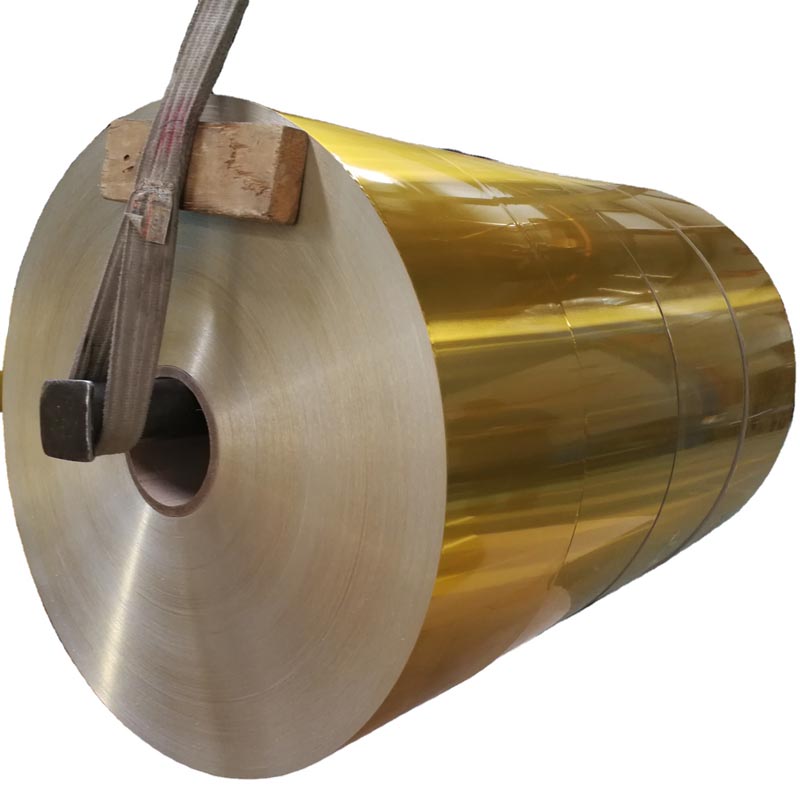

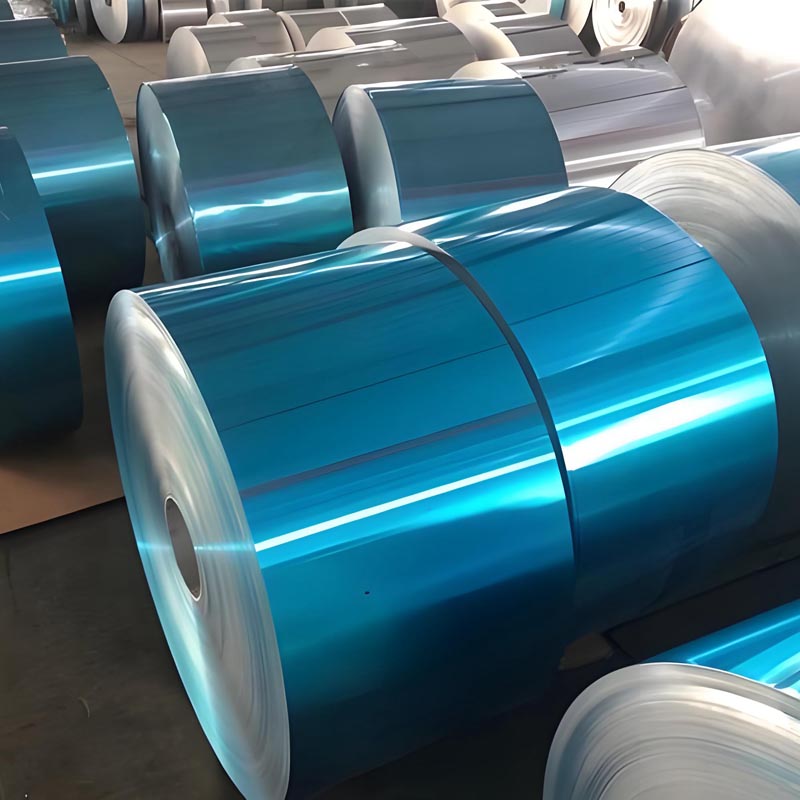

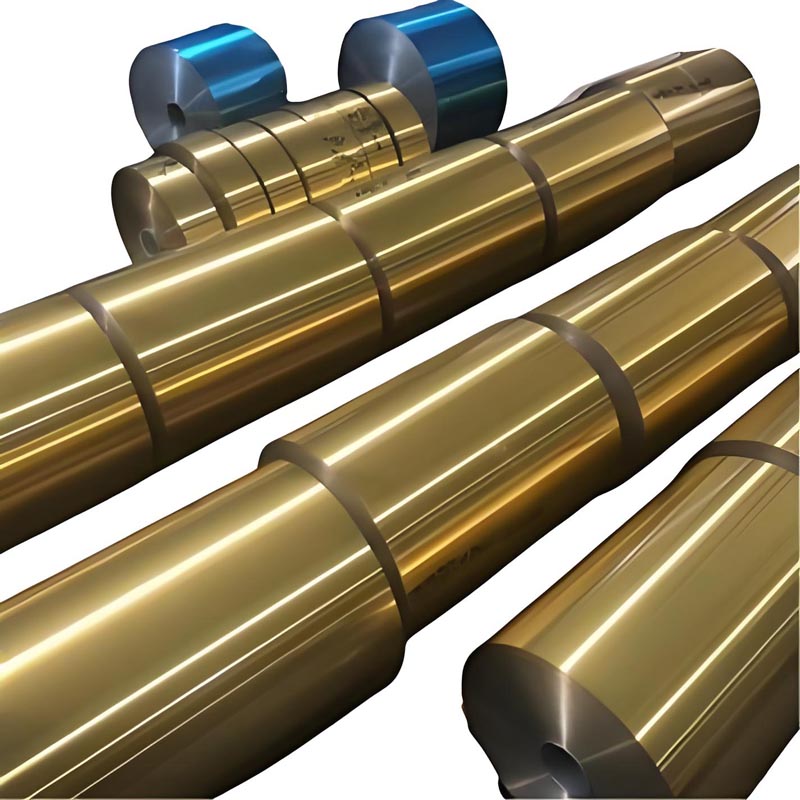

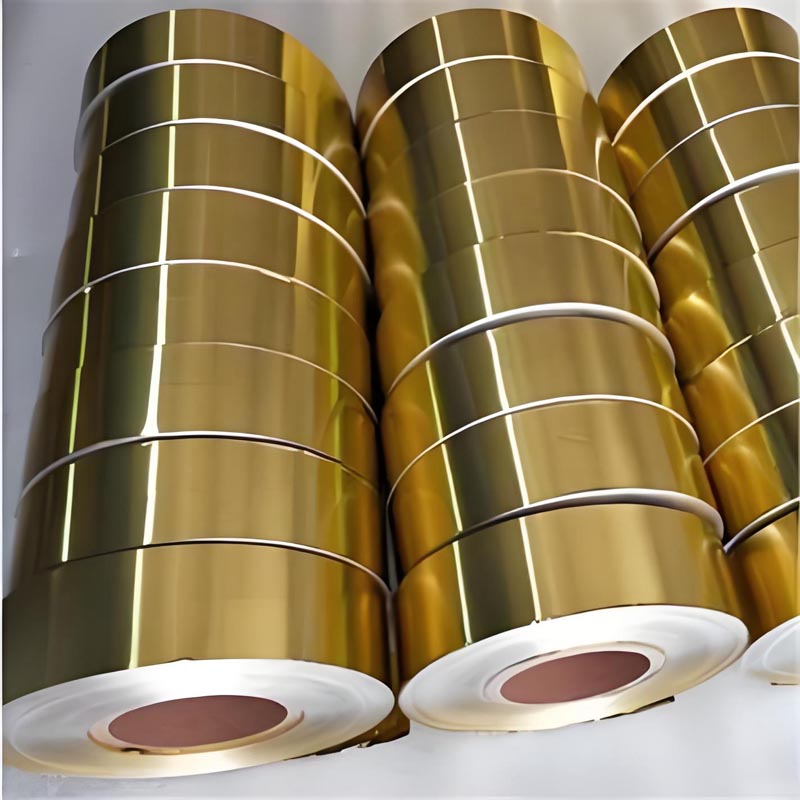

Wholesale 1100/1030B/3102/8011 Epoxy-Coated Aluminum Foil for Air Conditioner Heat Exchangers

Epoxy-coated aluminum foil is widely used in air conditioner heat exchangers, HVAC condensers, evaporators, and radiator fins. It offers high thermal conductivity, excellent corrosion resistance, and strong coating adhesion, significantly improving system efficiency, durability, and service life.

We supply 1100/1030B/3102/8011 series aluminum foils in bulk, ensuring stable mechanical performance and uniform coating quality. Our production standards meet the requirements of international air conditioner manufacturers and fin processing factories.

Product Overview

1100 Aluminum Foil: Pure aluminum (≥99.0%), low strength, excellent plasticity, easy to process, and high thermal conductivity. Ideal for general fins and household AC heat exchangers.

1030B Aluminum Foil: Pure aluminum alloy, designed for high-performance AC fins, with higher mechanical strength, excellent stamping performance, and thermal conductivity. Highly compatible with epoxy resin and hydrophilic coatings.

3102 Aluminum Foil: Al-Mn series alloy, offering improved strength and compression resistance, along with excellent anodizing and coating adhesion. Widely used in large HVAC systems and commercial AC units.

8011 Aluminum Foil: Al-Fe-Si series alloy, with excellent overall performance, durability, and formability. Commonly used for hydrophilic and epoxy-coated condenser foils.

Key Features

- Excellent Heat Transfer Efficiency: Aluminum foils made from 1100/1030B/3102 alloys ensure rapid heat dissipation and enhance AC system performance.

- Hydrophilic Performance: Condensed water spreads evenly across the fin surface, flows away quickly, and avoids water bridging, maintaining uninterrupted airflow and efficient heat exchange.

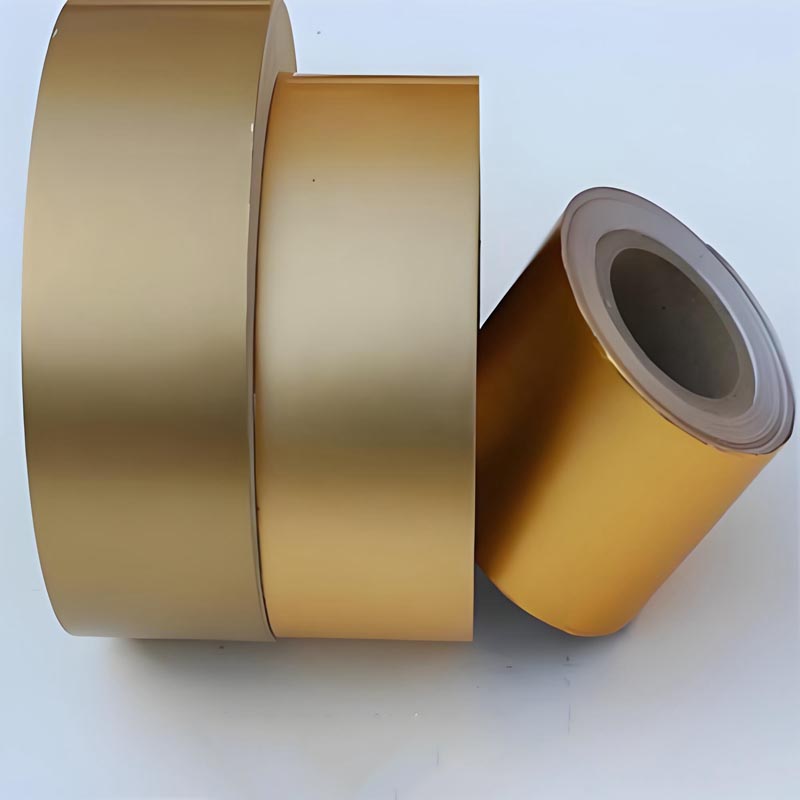

- Uniform Coating: Advanced roll-coating production lines guarantee consistent thickness and color.

- Excellent Formability: Perfect for fin stamping and high-speed production, without cracking or powder shedding.

- Long-Lasting Corrosion Resistance: Suitable for coastal, high-humidity environments, and long-running condensers.

- Anti-Mold Performance: Effectively inhibits bacteria and mold growth on fin surfaces, improving air quality and supporting modern healthy AC design trends.

Technical Parameters

Alloy: 1100 / 1030B / 3102 / 8011

Temper: O, H22, H24, H26

Thickness: 0.08-0.20 mm (customizable)

Width: 100-1400 mm

Length: 1000-16,000 mm

Coating Type: Epoxy resin / Hydrophilic / Anti-corrosion

Color: Gold, Blue, Black, etc.

Coating Thickness: 2-15 μm

Tensile Strength: 100-180 MPa (depending on alloy)

Elongation: 10%-20%

Surface: Epoxy coating / Hydrophilic coating

Core: Aluminum / Steel (75 mm / 150 mm)

Packaging: Standard export wooden boxes + moisture protection

MOQ: 1-3 tons

Applications

AC heat exchangers (fin stock)

HVAC evaporator and condenser fins

Commercial and industrial AC systems

Refrigeration equipment

Heat pump coils

Radiator fins

Company Profile

We are a leading aluminum foil manufacturer, specializing in epoxy-coated aluminum foil, hydrophilic aluminum foil, HVAC fin materials, and 1xxx/3xxx/8xxx series aluminum products. With over 20 years of experience, we have become a trusted supplier for global air conditioner manufacturers and heat exchanger factories.

Factory Highlights:

Advanced continuous coating production lines

Multiple precision slitting machines

High-standard surface treatment workshops

In-house laboratory for coating testing (salt spray, boiling water, adhesion tests)

We export to 60+ countries, including Europe, Southeast Asia, the Middle East, South America, and Africa. Our monthly production capacity exceeds 2,000 tons, supporting large-volume orders, OEM/ODM projects, and long-term supply contracts.

FAQ

Q1: Are you a trading company or manufacturer?

A1: We are a manufacturer with over 20 years of industry experience.

Q2: What payment terms do you accept?

A2: 30% TT as deposit, 70% TT / 70% LC at sight for the balance before shipment.

Q3: How long does it take for samples and mass production?

A3: After order confirmation, new molds and free samples (≤5 kg) usually take 15-20 days. Mass production takes 25-30 days.

Q4: Do you provide OEM/ODM services?

A4: Yes, we do!

Q5: Can you provide samples?

A5: Yes, free samples are available for quality inspection. Shipping and taxes are borne by the buyer.

Q6: Do you accept sample orders?

A6: Yes, we accept sample orders.

Send product request

Other supplier products

| Wholesale aluminum closure for yogurt lid 8011 aluminum foil | Dairy products have complex components and are easily affected by temperature, oxygen, light, microorganisms, mechanical effects, etc., which can l... | |

| 3003 H14 H24 Aluminum Strip for Hollow Glass Strip Factory Price | Hollow glass aluminum strip is used for hollow glass strip spacers. The commonly used material is 3003 aluminum alloy. Its quality is directly rela... | |

| PE PVDF Color-coated Aluminum Coil 1100 3003 5052 5083 Construction/Transportation/Packaging Aluminum Alloy Coil | What is color-coated aluminum coil? After the aluminum coil is cleaned, chromized, roller-coated, and baked, the surface of the aluminum coil is c... | |

| 1235 Alloy Aluminum Foil for Chewing Gum Packaging and Flexible Packaging | 1235 aluminum foil is a high-purity aluminum material with an aluminum content of no less than 99.35%, containing minimal impurities. It complies w... | |

| Household aluminum foil customization 1235 8011 | Household aluminum foil is mainly used for cooking and decoration. In terms of cooking, aluminum foil can be used to store food, cover baking surfa... |