Quick repair method for rubber conveyor belt scratching

Quick repair method for rubber conveyor belt scratching

When conveyor belt running under high load capacity, whose surface will be torn or longitudinal scratching, if we don’t repair in time, it will be cause big affect to normal production, then affect the economic benefits of enterprises.

After it appears scratching problem, we have to do quick repair, because we have limit halt time. If we choose traditional hot splicing method, though stable and reliable, but it waste time and affect operation time. So whether we have a method to repair it in short time? The answer is positive.

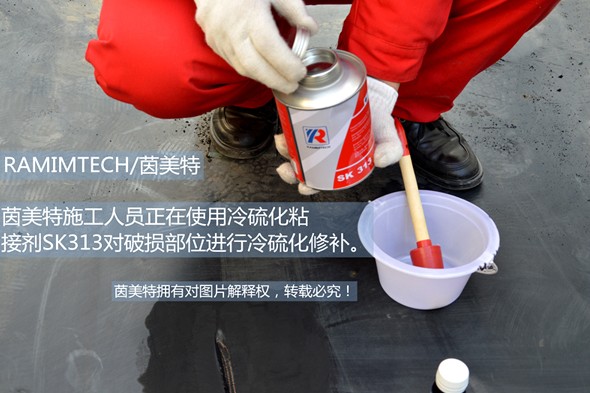

Ramimtech cold repair method choose high quality, abrasion resistant repair materials, applies the bonding technology that semi-cured layer bonding with cold vulcanizing glue sk313,not only easy construct, but also reliable technology, after repair, we can operate it immediately, which saves halt time and enhance the repair efficiency.

Repair methods for conveyor belt repair

First step: sand damaged parts, mark the damaged area, the marked part should be larger than the damaged part, then use the angle grinder L1202 together with K23 tungsten carbide buffing disc to sand the damaged part until the damaged part present a certain radian and no protrusion.

Second step: clean damaged parts, use brush to clean it, then use cleaning solvent to deeply clean it, wait until it dries.

Third step: brush cold vulcanizing adhesive, brush a coat of cold vulcanizing glue SK313 on damaged parts until it totally dry. Then brush cold vulcanizing glue SK313 the second time, meanwhile, repair strip whose semi-cured layer should brush a coat of cold vulcanizing glue SK313, until both of them have little stickiness and begin to bond them.

Forth step: combine repair strip along the damaged parts, avoid air in, after combine, use hand roller to press the repair parts from inner parts, and discharge air.

Notice:

If conveyor belt repair parts appears pierce through or pierce pass phenomenon, we should bond the working part and non-working part with repair strip, and fill the damaged parts with rubber repair agent SK786, then directly bond the repair strip.

Apply Ramimtech cold vulcanizing repairmethods, which suitable for Power Plant, Steel plant, coking plant, cement plant, granary, mine, dock and subway units, the technology is easy operation, no need for big equipment such as vulcanizing machine, which can realize quick repair to damaged parts, after repair, it can reach the work intensity immediately, and start-up and use.

Send product request

Other supplier products

| Ramimtech repair strip | Ramimtechrepair strip Ramimtech repair strip is a special material for conveyor belt repair, which is suitable for conveyor belt surface damage, sc... | |

| Ramimtech hot vulcanzing agent STL HS | Ramimtech hot vulcanzing agent STL HS Ramimtech hot vulcanizing agent is non-flammable,it is one of the indispensable materials of conveyor belt ho... | |

| Which kind of cover rubber is better for conveyor belt joints? | Which kind of cover rubber is better for conveyor belt joints? Which kind of cover rubber is better for conveyor belt joints? It depends on the qua... | |

| Quick Cold vulcanizing repair adhesive SK811 | Quick Cold vulcanizing repair adhesive SK811 In recently,RAMIMTECH construction workers have done conveyor belt repairing successfully by using qui... | |

| Belt repair glue SK811 | Belt repair glue SK811 When conveyor belt running for a long time, whose surface will be partly damaged, however, we should not regardless this dam... |

Same products

| Aluminum Extrusion 6063 scrap | Seller: Willies De Scrap Inc | Are you looking for aluminum extrusion 6063 or any other type of scraps and then you are welcome ... | |

| RUBBER ROLLER | Seller: THAKORJI TECHNOMECH | Rubber Roller Silicon Roller PU Rubber Roller Aluminium Roller- | |

| RUBBER ROLLER | Seller: THAKORJI TECHNOMECH | ||

| RUBBER ROLLER | Seller: THAKORJI TECHNOMECH | ||

| " EP/NN/CC high tensile strength Conveyor Belt with heavy load capacity and good elasticity" | Seller: Haichuan Belting Co.,Ltd | .It uses ployester canvas as carcass, and its structure is the same as that of General-used Conve... |