Steel Bar Testing

The steel bar is rolled by a rolling mill and produce both surface defects and internal defects during the rolling process. The internal defect is that the original defects of the steel chain or billet are extended during the rolling process. These defects are mainly concentrated in the central part of the steel rod. The forms mainly include slag inclusion, shrinkage, delamination, and looseness. The amount of rolling deformation increases and increases. In actual production, these internal defects of the steel rod have a serious impact on the performance of the steel. For example, steel rods used for forging, these internal defects will continue to exist inside the steel rod during the forging process, and some will continue to extend. Some will form a mezzanine. Therefore, the non-destructive testing of the internal defects of steel bars has attracted more and more attention.

Wireless Transmission Steel Bar Ultrasonic Flaw Detector

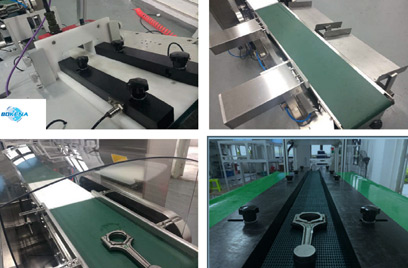

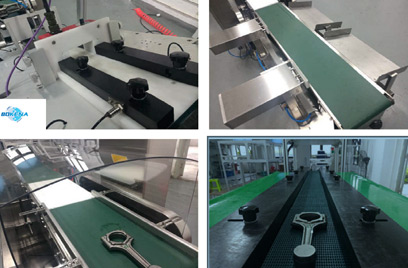

Steel bar is a conventional product with high density, moderate noise. The system is suitable for automatic detection of internal and external defects of various steel bars.

LEARN MORE >

Wireless Transmission Steel Bar Ultrasonic Flaw Detector

Ultrasonic automatic detection system for steel bars

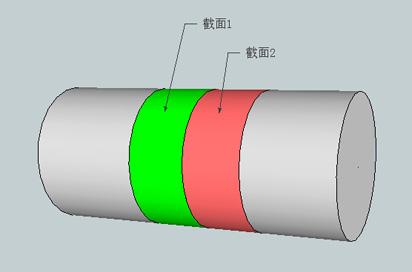

The ultrasonic automatic detection system for steel bars is a device that uses ultrasonic longitudinal wave detection to detect defects such as delamination and inclusions inside the steel bar. The steel rod enters a six-way ultrasonic probe that rotates at a high speed through a communication mechanism, and each channel is set to a different frequency. The steel rod advances at a low speed, so it can cover 100% of the surface of the steel rod. After the steel rod enters the ultrasonic system, the system begins to detect.

When a defect is detected, the probe will feed back the defect signal. The defect signal is processed, amplified, converted to the oscilloscope, and the oscilloscope is transmitted to the computer. The program in the computer responds accordingly, that is, the defect location is identified. In the subsequent production, the marked steel bar will be cut off, thereby avoiding the quality problems caused by the internal defects of the steel bar.

As a non destructive testing equipment manufacturer and supplier, we have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

BKNis a professionalmfl suppliers. We provide Eddy Current Testing, Magnetic Flux Leakage Testing, ndt testing, ultrasonic testing of steel bars, steel bar testand so on. Want to know more? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Steel Bar Testing | The steel bar is rolled by a rolling mill and produce both surface defects and internal defects during the rolling process. The internal defect is ... | |

| Eddy Current Testing Equipment | ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals ... | |

| Wireless Transmission Pipe Ultrasonic Flaw Detector | The ultrasonic pipe testing equipmentsystem is suitable for the automatic detection of various internal and external defects of steel pipes. The pr... | |

| EDM Notch | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testingis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. A... |

Похожие товары

| Micronized polypropylene wax for injection moulding | Продавец: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Продавец: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |