Overflow Ball Mill

CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold directly to end customers, business partners, and EPC projects. As a professional heavy equipment companies, CIC serves multiple roles, such as, cement machinery suppliers, mining machinery manufacturers, grinding mill manufacturer, rotary kiln manufacturer, rotary dryer manufacturer, sludge dryer manufacturer and so on.

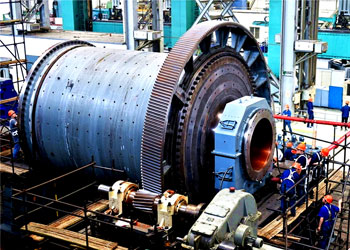

In recent years, with the continuous development of grinding technology, wet grinding has become the mainstream process, overflow ball millis the most widely used equipment in wet grinding. Overflow type ball millis mainly used for wet grinding of all kinds of ores. In the grinding process, raw materials and water are added at the same time to make the ground fine materials form pulp with water, which is discharged in the way of self flow, so as to complete the grinding operation, so it is called overflow ball mill.

Features of Overflow Ball Mill

lEasy to start, stable operation

lSimple structure, convenient maintenance

lVarious working modes and optional granularity

lThe grinding time is short and the service life is long

Application of Overflow Ball Mill

Overflow ball mill is often used for grinding fine ore or regrinding concentrate in mineral processing industry. In addition, it can also be used in silicate products, building materials, chemical fertilizers, non-ferrous metals, glass ceramics and other production industries.

Working Principle of Overflow Ball Mill

When overflow ball mill is working, raw materials and water are continuously added from one port, and the slurry is formed after being ground by steel ball inside the cylinder. After the slurry is ground to the target size and accumulated to a certain height, it will overflow from the other end.

Advantages of Overflow Ball Mill

lRich Experience: We have produced hundreds of overflow ball mill typesevery year. We ensure the quality and provide after-sales service. The product has a long service life.

lStrong Production Capacity: We can make quick delivery with our 6 factories and 800+ workers.

lReasonable Price: we have long-term cooperation with hundreds of suppliers, and will lower the cost of raw materials and processing.

Intelligent Grinding Expert System-Ball Mill

To realize the intelligent control for cement ball milloperation, we provide the intelligent grinding expert system. It will monitor the situation of ball mill working and the finished products status. Lower the labour cost with great efficient. Learn More...

Technical Properties List of Overflow Ball Mill

|

Specification |

Shell Diameter |

Shell Length |

Volume |

Rotary Speed |

Grinding Medium Load |

Transmission Type |

Motor |

Profile Dimensions |

Total Weight |

Remarks |

|

|

mm |

mm |

M3 |

r/min |

t |

Power(kw) |

Rotary Speed(r/min) |

(L×W×H)m |

t |

|||

|

MQY15×30 |

1500 |

3000 |

5 |

9 |

Side-edge Transmission |

95 |

742 |

Drum Feeder |

|||

|

MQY15×36 |

1500 |

3600 |

95 |

742 |

Rubber Liners |

||||||

|

MQY18×61 |

1830 |

6100 |

220 |

736 |

|||||||

|

MQY21×30 |

2100 |

3000 |

15 |

200 |

740 |

45 |

|||||

|

MQY24×30 |

2400 |

3000 |

21 |

250 |

980 |

55 |

|||||

|

MQY24×70 |

2400 |

7000 |

21 |

48 |

475 |

740 |

67 |

Rubber Liners |

|||

|

MQY27×36 |

2700 |

3600 |

39 |

400 |

|||||||

|

MQY27×40 |

2700 |

4000 |

38 |

400 |

70 |

||||||

|

MQY27×45 |

2700 |

4500 |

500 |

76 |

|||||||

|

MQY27×40 |

2700 |

4000 |

53 |

630 |

589 |

Rubber Liners |

|||||

|

MQY28×54 |

2800 |

5400 |

30 |

630 |

167 |

13×5.83×4.7 |

|||||

|

MQY28×80 |

2800 |

8000 |

43 |

20 |

800 |

137 |

115 |

For coal water slurry |

|||

|

MQY30×110 |

3000 |

11000 |

100 |

Central Transmission |

1250 |

429 |

|||||

|

MQY32×36 |

3200 |

3600 |

Side-edge Transmission |

500 |

167 |

||||||

|

MQY32×40 |

3200 |

4000 |

60 |

560 |

980 |

||||||

|

MQY32×45 |

3200 |

4500 |

630 |

167 |

13×7.0×5.82 |

||||||

|

MQY32×54 |

3200 |

5400 |

73 |

800 |

167 |

129 |

|||||

|

MQY32×64 |

3200 |

6400 |

86 |

1000 |

167 |

140 |

|||||

|

MQY32×75 |

3200 |

7500 |

102 |

1250 |

734 |

154 |

|||||

|

MQY32×90 |

3200 |

9000 |

1250 |

150 |

173 |

||||||

|

MQY34×45 |

3400 |

4500 |

37 |

800 |

167 |

||||||

|

MQY34×56 |

3400 |

5600 |

1120 |

985 |

|||||||

|

MQY36×45 |

3600 |

4500 |

76 |

1000 |

167 |

13×7.3×6.3 |

|||||

|

MQY36×50 |

3600 |

5000 |

1250 |

167 |

15×7.6×6.2 |

150 |

|||||

|

MQY36×50 |

3600 |

5000 |

Central Transmission |

1250 |

429 |

23×4.6×6.3 |

176 |

||||

|

MQY36×56 |

3600 |

5600 |

Side-edge Transmission |

1250 |

750 |

||||||

|

MQY36×60 |

3600 |

6000 |

Central Transmission |

1250 |

429 |

24×4.6×6.3 |

|||||

|

MQY36×60 |

3600 |

6000 |

54 |

102 |

Side-edge Transmission |

1250 |

167 |

||||

|

MQY36×61 |

3600 |

6100 |

1200 |

980 |

|||||||

|

MQY36×85 |

3600 |

8500 |

79 |

131 |

1800 |

743 |

20×8.2×7.1 |

||||

|

MQY36×90 |

3600 |

9000 |

138 |

Central Transmission |

1800 |

743 |

28×4.6×5.6 |

286 |

|||

|

MQY38×67 |

3800 |

6700 |

70 |

130 |

Side-edge Transmission |

1400 |

743 |

19×8.2×7.1 |

|||

|

MQY40×60 |

4000 |

6000 |

16 |

126 |

1500 |

200 |

|||||

|

MQY40×67 |

4000 |

6700 |

16 |

1600 |

200 |

||||||

|

MQY40×135 |

4000 |

13500 |

155 |

16 |

233 |

3300 |

200 |

23×10×4.9 |

343 |

For coal water slurry |

|

|

MQY43×61 |

4300 |

6100 |

80 |

144 |

1750 |

200 |

14×10×7.7 |

||||

|

MQY50×64 |

5030 |

6408 |

120 |

251 |

2600 |

200 |

|||||

|

MQY50×83 |

5030 |

8300 |

266 |

3300 |

200 |

22×10.5×9 |

|||||

|

MQY55×65 |

5500 |

6500 |

264 |

3400 |

200 |

||||||

|

MQY55×85 |

5500 |

8500 |

335 |

4500 |

200 |

||||||

在线联系供应商

Other supplier products

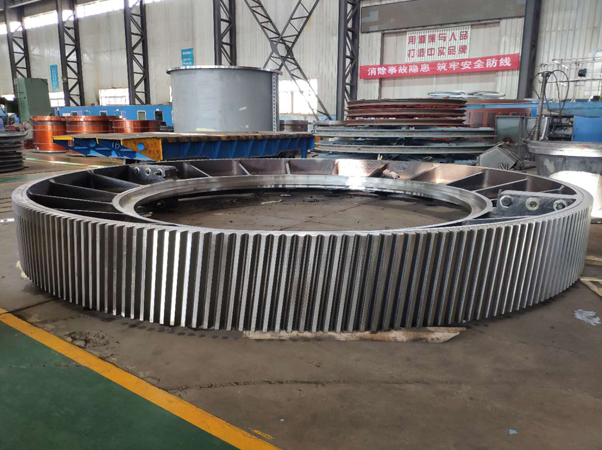

| Girth Gear | CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VO... | |

| Liner | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Overflow Ball Mill | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| CIC Mining And Cement Equipment | CIC's heavy machinery equipment include not only market-leading standardized products, but also customized products and related services according ... | |

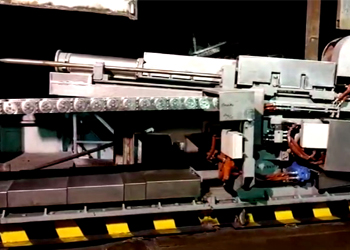

| Furnace Robotic Arm Machine | With the development of modern science and technology, industrial arm is a kind of high-tech automatic intelligent mechanical production equipment ... |

Same products

| Micronized polypropylene wax for injection moulding | 卖方: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | 卖方: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | 卖方: XIUCHENG RFID | ize:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transfe... | |

| Micronized wax used for industrial paint processing | 卖方: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | 卖方: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |