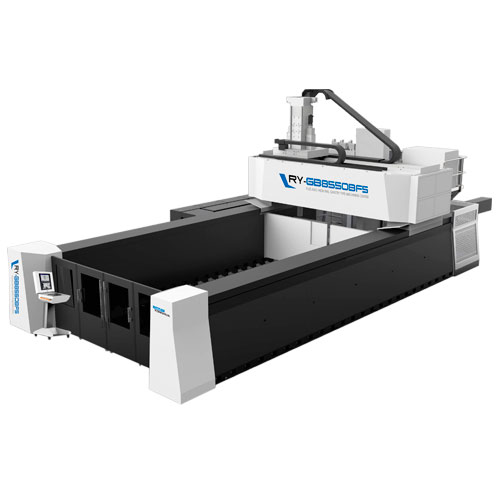

PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE

The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut preloaded ball screw. The machine tool guide rail adopts the roller linear rolling guide rail pair. The X-axis and Z-axis adopt the three guide rail design to ensure the high bearing and high stability of the deed machinetool.

FEATURES OF PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE

X/Z axis adopts three imported heavy-duty roller linear guide rails, imported ball screw pair, fully closed telescopic shield, and fully closed-loop control. Two-speed reduction gearbox plus one-stage gear is adopted for deceleration, with the maximum speed of 2000, the maximum output torque of 2000Nm, the maximum reduction ratio of 1:14.46, and the minimum reduction ratio of 1:2.63. The spindle bearing adopts FAG special bearing, which is cooled and lubricated by thin oil circulation, so as to ensure the long-term and high-precision operation of the spindle.

HOW DOES PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE WORK?

The planer type horizontal boring machineis suitable for processing various kinds of basic large parts, plates, discs, shell parts, molds and other parts with large and medium size, large and medium weight. After one-time workpiece clamping, a variety of processing such as milling, drilling, boring and reaming can be continuously completed with the characteristics of automatically, efficiently and accurately.

WORKING PRINCIPLE OF PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE

The planer type horizontal boring machinetool is column movable, with a single column, transverse base, and side hanging spindle box layout, and is equipped with a tool and workpiece cooling system, The transverse (x-axis) feeding movement of the machine tool is realized by the transverse movement of the worktable along the bed, the longitudinal (Z-axis) feeding movement of the machine tool is realized by the longitudinal movement of the spindle box and column along the longitudinal base, the vertical (Y-axis) movement of the machine tool is realized by the up and down movement of the spindle box along the column, and the longitudinal movement of the boring bar is realized by the movement of the boring bar in the spindle box sleeve (W-axis), the worktable can realize 360 ° continuous rotation of B coordinate on the sliding saddle (with four-point precise positioning function), the arbitrary indexing positioning function of the rotary table is realized through disc spring clamping and hydraulic loosening.

PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE SPECIFICATION

PBC1120PBC1330/40

|

Model |

Unit |

PBC1120 |

||

|

Boring spindle |

Diameter |

mm |

110 |

|

|

Taper type |

BT50 |

|||

|

Spindle motor |

kW |

|||

|

Max torque |

Nm |

2000 |

||

|

Max speed |

rpm |

2500 |

||

|

CNC rotary table |

Worktable |

m |

||

|

Positioning accuracy |

" |

±6 |

±6 |

|

|

Repeatability |

" |

±3 |

±3 |

|

|

Load capacity |

Kg |

8000 |

100000 |

|

|

Travel distance |

X-axis |

mm |

2000 |

|

|

Y-axis |

mm |

1600 |

||

|

Z-axis |

mm |

1200 |

||

|

W axis |

mm |

600 |

||

|

Feed speed |

Transverse (X) |

mm/min |

2-6000 |

|

|

Vertical (Y) |

mm/min |

2-6000 |

||

|

Longitudinal (Z) |

mm/min |

2-6000 |

||

|

Axial (W) |

mm/min |

2-2000 |

||

|

Rapid traverse |

Transverse (X) |

mm/min |

10000 |

|

|

Vertical (Y) |

mm/min |

10000 |

||

|

Longitudinal (Z) |

mm/min |

10000 |

||

|

Axial (W) |

mm/min |

3000 |

||

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| CNC HORIZONTAL TURNING LATHE CENTER FOR WHEEL HUB | The CNC horizontal turning lathe center bed adopts "mineral casting" material and technology of Germany, which guarantees DEED CNC horizontal turni... | |

| CNC MACHINING CENTER | CNC milling machine is automatic processing equipment developed on the basis of a general milling machine. Their processing technology is basically... | |

| 5 AXIS GANTRY MACHINING CENTER | 600*600mm large cross-section ram to ensure that even when the ram is overhung, it maintains strong cutting rigidity. X/Y axes are each equipped wi... | |

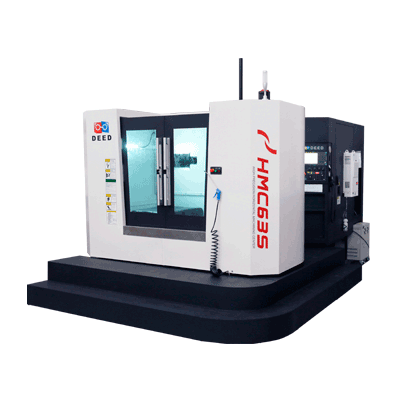

| Horizontal Machining Center For Sale | single station CNC horizontal machining center is suitable for various heavy cutting and high precision machining fields CNC HORIZONTAL MACHI... | |

| PBC SERIES PLANER TYPE MILLILING AND BORING MACHINE | The X/Y/Z servo axis adopts the servo motor direct connected precision planetary reducer to drive the large-diameter, high-precision double nut pre... |

Похожие товары

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Продавец: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Продавец: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... | |

| Fungicide Supplier | Продавец: HEBEI LAIKE BIOTECH CO.LTD | Fungicide Supplier Wholesale Fungicide - Laike Biotech is a professional supplier and manufa... |