CNC Boring

CNC boringis used for the shaft sleeve in the transmission shaft of large equipment, and the tolerance of the bearing position is +0.03mm. After welding the accessories, use CNC horizontal boring and milling equipment to process both sides with a concentricity of 0.05mm.

CNC Boring Capabilities

CNC horizontal milling and boring machine are suitable for machining large and medium-sized parts and box parts rough and fine boring, milling, and other processes. The worktable is equipped with 4x90 ° optical positioning device, which can meet the requirements of large parts turning. The CNC horizontal milling and boring machine are suitable for the hole and plane processing of box parts with many processes, turning of a cylindrical surface, cutting of annular groove in the hole, tapping of male and an English screw thread with a tap, etc. It also has the technological functions of the rectangular coordinate system, polar coordinate system and contour processing of CNC machine tool. The CNC horizontal milling and boring machine is a high-efficiency and precision technique of advanced precision machiningChina.Because the CNC horizontal milling and the boring machine have high rigidity and closed-loop detection system, which can meet the requirements of rough and fine machining.

Advantage of CNC Boring

CNC boring and milling machining has the characteristics of strong rigidity, high machining accuracy and efficiency, good stability, long transverse travel, large bearing capacity and powerful cutting. CNC boring and milling machining is a kind of extreme precision machining. It is especially suitable for the boring and milling of the large planes and the finishing of large box parts and hole series. In addition to drilling, boring, expanding and reaming, various accessories can also be used for turning, milling and screw pattern processing.

As a leading CNC machining manufacturing company in China, ETCN offers high-precision CNC machining and manufacturing services covering different fields in China CNC grinding services like iron metal casting services, CNC machining (including plastic) services, CNCmanufacturing services, CNC milling services, CNC punching services and CNC turning services.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Extrusion Molding | Extruded Molding The products are processed by injection molding extruder, with a smooth surface and high dimensional accuracy. Products of differ... | |

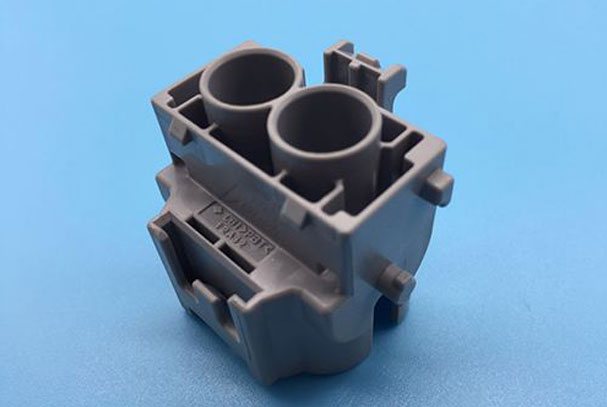

| Plastic Injection Molding | Plastic injection mold and moldingis a method of using an injection machine to quickly inject molten plastic into a mold and solidify it to obtain ... | |

| Progressive Die Stamping | As a professional progressive die manufacturer, ETCN provides progressive die tooling, petroleum equipment accessories, processes include stamping,... | |

| Cold Forging | As a professional cold forging manufacturer, ETCN provides our clients with cnc manufacturing servicesand cold forging die with different types of ... | |

| Die Casting | Die Casting As a professional aluminum die casting co inc, ETCN provides our clients qualified mould die castingservice. The product uses a die-ca... |

Похожие товары

| MaAnt M061 олово волочения иглы FPC разъем позолоченный припой бар | Продавец: Shenzhen Wikshu Technology Co. | Набор паяльных штифтов MaAnt M061 с золотым покрытием и легкой ручкой из углеродного волокна для ... | |

| High Hardness Linear Rail Flat Bed CNC Lathe | Продавец: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | It can cut all kinds of turning surfaces by bicycle, such as conical surfaces, special surfaces, ... | |

| Automation Suction Cups | Продавец: Zhejiang Shijing Tools Co., Ltd. All Rights Reserved. | The ALUMINUM SUCTION CUP 6106 D is a versatile and reliable tool designed to handle various lif... | |

| Machinery | Продавец: O&K GROUP LIMITED | Okwishing supplies all kinds of Machinery. Okwishing () is a cross-border e-commerce platform de... | |

| Mini Excavator Carrier Roller for Kobelco SK045/SK045SR/SK50SR/SK70SR | Продавец: Xiamen Globe Truth (GT) Industries Co., Ltd | The carrier roller use 50Mn steel, after free forging into work-piece by a 560KG air hammer, comp... |