Оборудование для вихретокового контроля для труб, проволоки

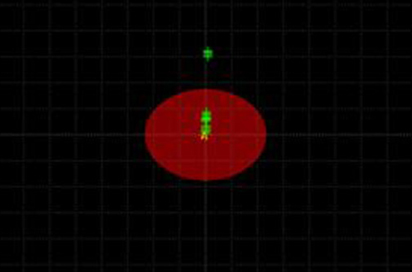

ECT Eddy current testing is a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals to detect. It is one of the NDT non-destructive testing methods in the industry.

We can use different coils according to the shape of the specimen and the purpose of detection. There are usually three types of coils: through a coil, probe coil and insert coil. It is mainly used for the rapid detection of metal pipes, rods and wires on production lines, and for the detection of large quantities of parts such as bearing steel balls, valves, etc.

The main features of eddy current machine for sale:

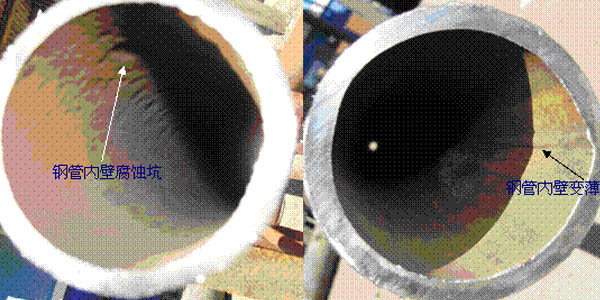

1) The detection sensitivity of the surface of the conductive material and the near surface defects is high;

2) A wide range of applications can be monitored for various physical and technological factors affecting eddy current testing;

3) It is easy to realize high-speed, high-efficiency and automatic detection of tubes, rods and wires without using a coupling agent;

4) Under certain conditions, it can reflect information about the crack depth;

5) Monitoring can be carried out in the case where other detection methods such as high temperature, thin-walled tubes, thin wires, and inner surface of the parts are not applicable.

Eddy current tube testing equipment are mainly applicable to the surface defect detection of ferromagnetic non-ferrous metals, austenite, stainless steel tubes, rods and discs. It can be widely used for on-line or off-line NDT non-destructive testing of raw materials in energy, petrochemical, bearing, automobile, transom manufacturing, household appliances and other industries, such as bearings, raw materials of high strength bolts, copper, aluminum tubes of various refrigeration equipment, condenser tubes of evaporators, etc. This system is the necessary testing equipment for pipe and bar and wire production and application factory. This system adopts rotating balance point probe, resolver signal coupling, synchronously adjusting double detection probe, and the detection method of workpiece passing straight line. It has the characteristics of stable and reliable performance, high detection sensitivity, fast detection speed, no need for magnetizing and demagnetizing devices, and is sensitive to defect detection of pipe, bar and wire. It can make 100% NDT non-destructive detection of raw material surface. The equipment has the functions of defect alarm, automatic feeding and unloading and automatic sorting to achieve the detection automation. It provides an effective detection means for mass production of application pipes, rods and wires in factories and enterprises to ensure quality.

BKN has eddy current equipment for sale for sale, which has high detection sensitivity and is avaliable for a wide range of applications.

We have been committed to developing and manufacturing high-quality and high-performance NDT equipment to provide customers with the best quality service.

Why BKN NDT Testing Equipment

The technology of BKN originated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a leading high-tech ultrasonic testing equipment manufacturers in China. The company is committed to the development of eddy current, ultrasonic, magnetic flux leakage and various non-standard equipment, holding independent research and development of a number of national patents.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| BKNET-0102 Welded Pipe Eddy Current Flaw Detector | Eddy current weld testing is the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. ... | |

| Eddy Current Testing Equipment for Tube, Bar and Wire | ECT Eddy current testing is a ndt testing equipment, which mainly uses the electromagnetic field and electromagnetic induction between metals to de... | |

| Bolt Vortex Sorter BKNFX-11 | Bolt: Mechanical parts, cylindrical threaded fasteners with nuts. A type of fastener consisting of a head and a screw (a cylinder with an external ... | |

| Steel Pipe Testing | Steel having a hollow section that is much longer than the diameter or circumference. According to the cross-sectional shape, it is divided into ro... | |

| MFL-7389 Tube Magnetic Flux Leakage Detector | Tubing repair is an important measure to reduce the comprehensive cost of production in oil production plants to improve the quality of repairing t... |

Похожие товары

| UV Detector | Продавец: Xinsheng Pharmaceutical Instrument Co., Ltd | The ultraviolet-visible dual-wavelength detector features high sensitivity and a wide linear rang... | |

| Fabric ici pilling and snagging box | Продавец: Шанхайская компания Qianshi Precision Electromechanical Technology Co., Ltd | Fabric ici pilling and snagging boxis composed of the same speed motor drive, and to maintain the... | |

| Martindale Abrasion And Pilling Tester | Продавец: Шанхайская компания Qianshi Precision Electromechanical Technology Co., Ltd | To determine the abrasion and pilling resistance of all kinds of textile structures. Samples are ... | |

| Circular Locus Pilling Tester | Продавец: Шанхайская компания Qianshi Precision Electromechanical Technology Co., Ltd | Testing Standards: GB/T 4802.1. JIG 040-1990 Product Information: The Circular Locus Pilling... | |

| Bean Bag Snag Tester | Продавец: Шанхайская компания Qianshi Precision Electromechanical Technology Co., Ltd | Bean Bag Snag Tester, to determine the snagging and picking resistance of knitted and woven fabri... |