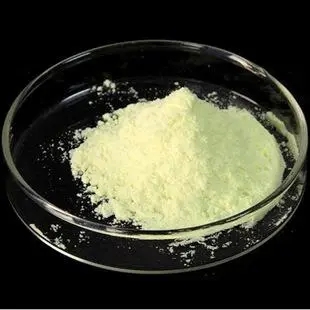

Phospholipid Powder

Phospholipids (e.g., lecithin from soybeans, egg yolks, or sunflower seeds) stand out in food processing due to their unique structural and functional traits, adapting to multiple product types and processing needs.

Their amphiphilic structure (with hydrophilic phosphate groups and hydrophobic fatty acid chains) enables multiple functions, reducing the need for multiple additives:

- Primary emulsifier: The most common use—stabilizing oil-water mixtures that are prone to separation. For example:

- In dairy products (milk drinks, ice cream): Prevents fat globule aggregation, making the texture smoother and extending shelf life by 10%–15%.

- In bakery products (bread, cakes): Emulsifies oil and water in dough, improving dough elasticity and reducing staling (stale rate decreases by 20%–30%).

- Nutritional fortifier: As a source of essential fatty acids (e.g., linoleic acid) and choline, it enhances the nutritional value of foods. For instance:

- In infant formula: Added to supplement choline (supports brain development) and improve the absorption of fat-soluble vitamins (A, D, E).

- In functional foods (protein bars, meal replacements): Used as a natural nutrient to replace synthetic additives, aligning with "clean label" trends.

- Texture modifier & antioxidant aid:

- In chocolate: Reduces viscosity during processing, making it easier to mold and giving a glossy surface; also slows fat bloom (white spots on the surface) by 50%–60%.

- In meat products (sausages, ham): Binds water and fat, reducing cooking loss (loss rate drops from 15% to 8%–10%) and keeping the texture tender.

Phospholipids work well with most food ingredients and processing conditions, with strong adaptability:

- pH stability: Effective in a wide pH range (3.0–8.0), suitable for acidic foods (fruit juices, yogurt) and neutral foods (milk, bread) without losing functionality.

- Heat resistance: Maintains emulsifying activity at temperatures up to 120°C (common in baking or sterilization), unlike fragile emulsifiers (e.g., some plant gums that degrade at high temperatures).

- Compatibility with other additives: Synergizes with stabilizers (e.g., carrageenan, xanthan gum) to enhance stability, or with antioxidants (e.g., vitamin E) to extend the shelf life of oil-rich foods (fried snacks, cooking oils).

Most commercial phospholipids are extracted from natural sources (soybeans account for ~80% of global production, followed by egg yolks), with no synthetic chemical residues. This makes them ideal for replacing synthetic emulsifiers (e.g., sodium stearoyl lactylate, SSL) in products targeting health-conscious consumers. For example:

- In organic foods: Compliant with organic certification standards (e.g., USDA Organic, EU Organic) to avoid synthetic additives.

- In plant-based foods (plant milk, vegan cheese): Used as a natural emulsifier to replicate the texture of animal-based products, with higher consumer acceptance than synthetic alternatives.

Другие товары поставщика

|

|

Phosphatidylserine |

Phosphatidylserine is a crucial phospholipid molecule with various important functions in the body. It supports neuronal function, maintains cell m... |

|

|

Key Considerations for Phospholipids in Applications |

Phospholipids are versatile ingredients in the food industry, with applications ranging from basic emulsification and stabilization to advanced nut... |

|

|

Phosphatidylserine |

Phosphatidylserine, also known as serine phosphatidylserine, diacylglycerol phosphoserine, is a kind of white or light yellow loose powder, can be ... |

|

|

Phosphatidylserine Powder |

Phosphatidylserine offers distinct benefits for athletes and fitness enthusiasts by targeting the muscle-cortisol axis, filling the gap in post-exe... |

|

|

important phospholipid |

Phosphatidylserine is present in the biofilms of all animals, higher plants, and microorganisms. It is a very important component of phospholipids ... |

Все товары поставщика

Похожие товары