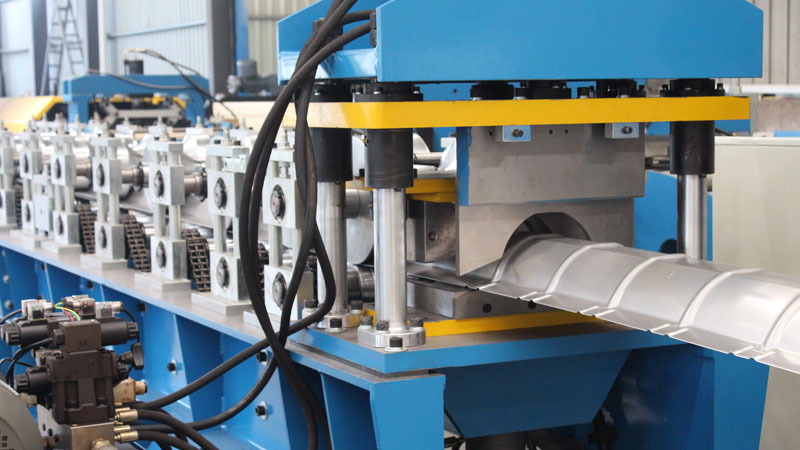

Rolling Shutter Door Roll Forming Machine

This series of rolling door machines are mainly used to make various rolling shutter door panels. Our rolling shutter slats roll forming machineis capable of not only forming the panels but also punching holes and embossing. And the profile of the panels can be customized. As a mature rolling shutter machine manufacturer, Hangzhou Roll Forming Technology possesses advanced technologies for producing rolling shutter profile machineand we conduct strict quality control during the whole production process. All of our roller shutter door roll forming machineare made with consistently high quality.

Features and Advantages of Rolling Shutter Door Roll Forming Machine

Roll Shutter Door Roll Forming line, specially designed for forming a rolling shutter door panel, under mass-production.

Production speed: 20/30/40/50/60 m/min optional.

Working with a non-stop flying cut and full automatically stacking system, Max speed of the line can reach 60 m/min.

Cassette-type platform quick-change Machine base for multi-profile purposes is available for choice.

Certified with Multi-Patents; CE Certified, EUROPEAN quality standard

For most hot & popular profile models, we have ready garage door roll formers in stock for prompt delivery.

Suitable Coil Sheet Material for Rolling Shutter Roll Forming Machine

|

Suitable material: |

Cold/hot Rolled Steel, Galvanized Steel |

|

Thickness: |

|

|

Yield Strength: |

230-300 (MPa) |

|

Width: |

Tailored in accordance with the customers' own requirements |

Production Line Components and Parameters of Rolling Shutter Roll Forming Machine

|

5t/8t/10t/15t Motor/hydraulic motor/passive (optional) |

|

|

optional |

|

|

optional |

|

|

no need |

|

|

20/30/40/50/60 m/min (optional) |

|

|

optional |

|

|

Motor/hydraulic (optional) |

|

|

Manual supporter/ Automatic Stacker (optional) |

|

|

Stackmaster |

(Output direction) Lateral/Longitudinal (optional) |

|

Power supply for decoiler /post-cutting system |

|

|

MITSUBISH/ SIEMENSE/AMS (optional or as requested) |

Working Flow of Rolling Shutter Roll Forming Machine

Pre-cutting flow:

Decoiler (passive/auto) → Feeding and Guiding Table →leveling system → hole punching system (as profile requests) → pre-cutting to length → Roll Forming System → Output Manual Supporter/Auto Stacker(optional)

Post-cutting flow:

Decoiler (passive/auto) → Feeding and Guiding Table →leveling system → hole punching system (as profile requests) → Roll Forming System → Post-Cutting to length (Hydraulic) → Output Manual Supporter/Auto Stacker(optional)

How Does A Roller Shutter Door Work?

The roller shutter door is a multi-joint movement of the door piece in series together, in the fixed slide, with the upper part of the door scroll as the center of rotation up and down the door. Roll shutter door is usually widely used in shops, garages, and industrial buildings.

Rolling shutter door has the effect of level space like the wall, it by curtain board, seat board, guideway, support, reel, box body, control box, roll door machine, limiter, door lintel, manual speed release close device, button switch, and insurance device many parts are composed, general installation is in the place that inconvenience build wall.

Specification ofRolling Shutter Roll Forming Machine

|

Machine Condition y |

Fully New, A-Grade quality |

|

Panel Shape |

As profile drawing and customer’s requirements |

|

Operator |

needed 1-2 persons |

|

Power Supply |

220V/380V/415V/460V, 50/60Hz, 3P (as requests) |

|

Equipment Weight |

About 15t |

|

Dimension |

(L*W*H) about 25*3*2m |

|

LOADING SIZE |

Normally need 1 x 40' container. |

|

Equipment Color |

Normally Blue/White, or as requests; |

|

Place of Origin |

Zhejiang, China (Mainland) |

|

Packing |

Standard and careful export packing |

As a professional tube mill supplier, we provide roll forming equipment for sale, roll forming machineand etc. Contact us to know roll forming machine specificationor buy our roll forming equipment.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Cold Roll Forming Machine | The cold roll forming machine is the equipment for continuously processing metal sheets of a coil, a strip, by a multi-pass forming roller which is... | |

| High Frequency ERW Pipe Mill Line | High-Frequency ERW Pipe Mill Lineis mainly used for making ERW welded steel pipes. ERW is short for Electric Resistance Welding. At present, ERW pi... | |

| Ridge Cap Roll Forming Machine | ridge cap machineIntroduction This machine is used to make ridge capping. Ridge capping is a critical part of the structure of a roof. Ridge cappi... | |

| AG PANEL ROLL FORMER | AG panel roll formeris a machine used in the manufacturing process of metal roofing panels. The machine is used to shape flat metal sheets into a c... | |

| AUTOMATIC ROOF SEAMING MACHINE | This electric seaming machineseries is assistant equipment for the roof roll forming machine. Seaming the roof panels, our electric roof seamer is ... |

Похожие товары

| Wide-Mouth Mold | Продавец: Taizhou Qihong Mold Co., Ltd. | A Wide-Mouth Mold is a specialized mold used to produce containers with a wider opening, often fo... | |

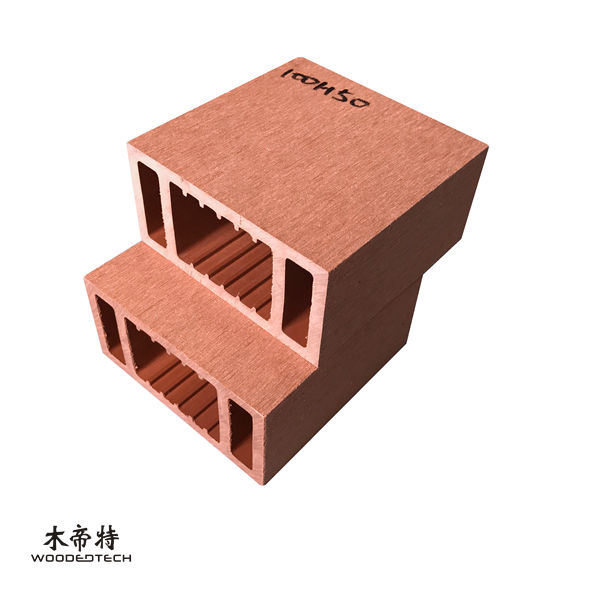

| Высококачественные наружные перила из деревопластикового композита (WPC) квадратной формы из Китая – прочное и стильное решение для ограждений | Продавец: Guangzhou woodedtech Co.,Ltd | Описание продукта: L10050 Квадратный поручень из древесно-пластикового композита (WPC) Преоб... | |

| Molybdenum Electrode | Продавец: Baoji City Changsheng Titanium Co.,Ltd | Molybdenum electrodemade by powder metallurgy technology with pure molybdenum powder has high mel... | |

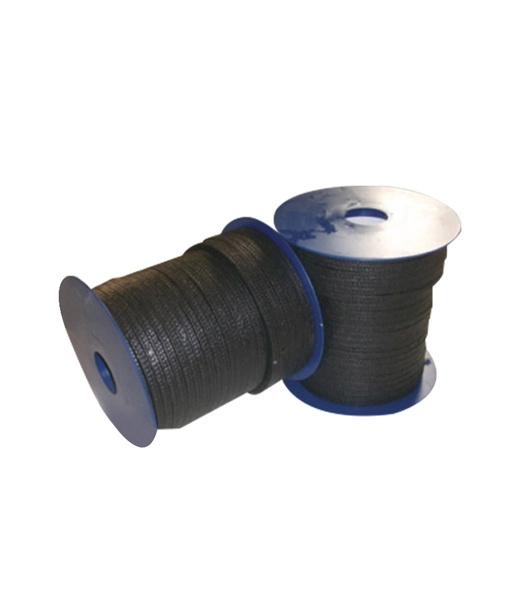

| PTFE Braided Packing | Продавец: Jiangsu Xinrui Plastic Technology Co.,Ltd | PTFE braided packingis a new type of sealing packing with desperse Teflon tape or tensile belt af... | |

| Molybdenum Boat | Продавец: Longhua Technology Group (Luoyang) Co., Ltd | Molybdenum boats are small, boat-shaped containers made of pure molybdenum or molybdenum alloys, ... |