SMC/BMC Framework

SMC/BMC Framework Description

Strong plasticity, precise size, high insulation and high temperature resistance.

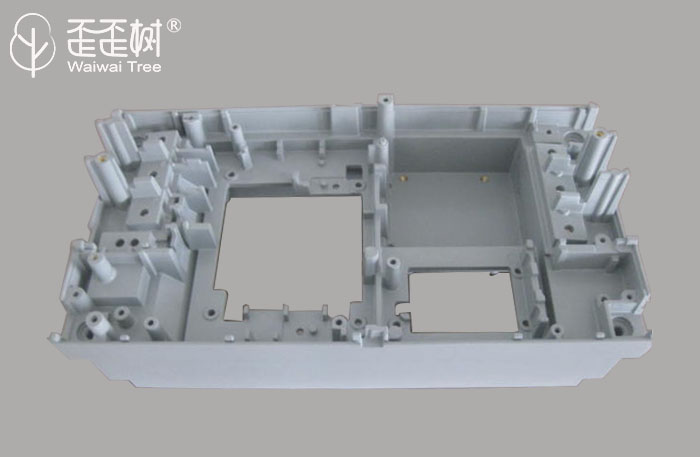

BMC molded framework is suitable for various framework. Because of its short glass fiber characteristics, this kind of BMC compositematerial is more suitable for complex components, such as electrical equipment, automotive components, electrical energy parts shell, and so on. Some BMC products are required to meet A-level surface requirements due to high precision, high quality, and appearance, and the construction period is completed on time.

SMC/BMC FrameworkManufacturer

Since the inverter frame size depends one the power of inverter, different inverter would have various frame size. BMC framework would not only help to improve production efficiency, but also help to save cost.

What Is Frame Moulding and Bmc Framework?

Molding is the process of forming liquid or other easy-to-use materials with a mold. A mold is a hollowed out container used to shape the material. Frame Moulding is to mold the material into frames for equipment, construction, electronic products, etc. Moulding frame is an important step of producing in many sections since many product would need an integrated framework.

BMC is a thermosetting plastic, mixed with various inert fillers, fiber-reinforced materials, catalysts, stabilizers, and pigments. According to the final application, compounds can be prepared to achieve strict size control, flame retardancy, high dielectric strength, corrosion and stain resistance, and color stability.

The Advantages of Bmc Framework

The excellent flow characteristics of BMC framework make them ideal for applications requiring accuracy and dimensional accuracy. BMC has many unique characteristics, such as high hardness, lightweight, corrosion resistance, UV resistance, good insulation, excellent thermal properties, which lead to more satisfaction than thermoplastic. At the same time, since many components can be molded at the same time with these components, there is no need for later processing, which is more economical from the production point of view.

Why Choose Aobang for Bmc Framework?

Waiwaitree is a professional supplier of BMC products and a reliable moulding for frames manufacturer. We are engaged in the design and manufacture of BMC products. We have a complete set of mould test line for BMC products and related moulding services. We have developed many BMC products, such as BMC insulation board, BMC shell, BMC flange, BMC household goods, etc. BMC frame owns many advantages that other materials cannot offer, and now, the BMC frame has become a popular choice in many sections. We can offer various services such as panel frame moulding, plastic frame moulding, etc.

For more information about bmc molding, please feel free to contact us!

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| SMC Cable Braket | The SMC cablebracket is a combination consisting of a cable bracket, a post and a fixed pin. The material of the column and the pin is also made by... | |

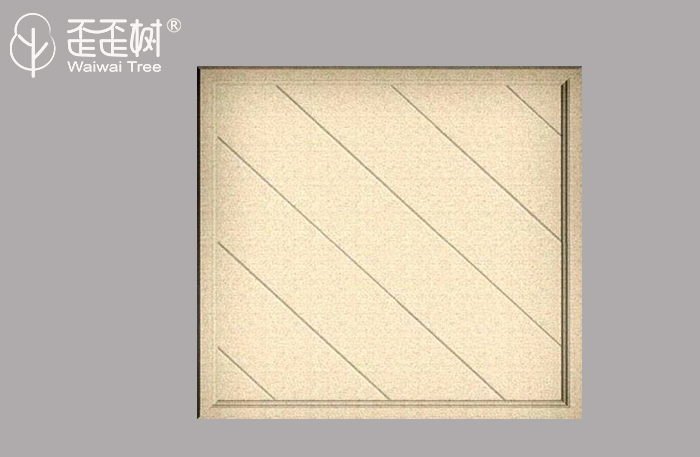

| BMC, SMC, GRP, GFK Wall Panel | Aobang composite Wall Panel is divided into: BMC Wall Panel, SMC Wall Panel, GRP Wall Panels, GFK Wall Panel. Composite Wall Panel the main fun... | |

| BMC, SMC, GRP, GFK Roof Tiles | Aobang composite roofing tiles is divided into: BMC roofing tiles, SMC roofing tiles, GRP roofing tiles, GFK roofing tiles. Due to the excellent p... | |

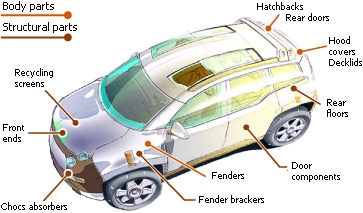

| SMC Automotive Molding, Car Mould | SMC AutomotiveMolding, Car Mould Cars, buses, trucks, transport and special vehicles • Weight: Parts made from sheet molding compound (... | |

| BMC/SMC Insulation | High-strength, wear-resistant, fire-resistant, color BMC material for medium and low voltage insulators such as SMC Insulated. Typical applicat... |

Похожие товары

| SMC/BMC Framework | Продавец: ZHEJIANG AOBANG TECHNOLOGY CO.,LTD | SMC/BMC Framework Description Strong plasticity, precise size, high insulation and high temper... |