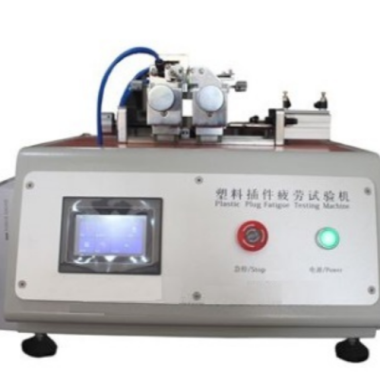

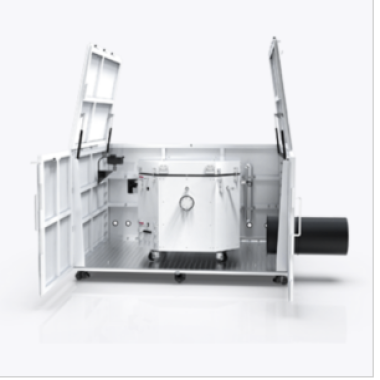

Bag Plastic Buckle Durability Tester

It is mainly used to test the service life of plastic plug-ins in luggage accessories.

Applications

This machine simulates the use of plastic clasp under reciprocating open and close movement to a specified number of times at a certain frequency. And testing the quality of plastic clasps for luggage and clothing.

Standards

QBT 5247-2018:Hardware fitting of case and bag-Test method for durability of plastic buckle

Features

1. We have a strong after-sales service team;

2. We can handle various problems promptly and efficiently, relieving our customers of any worries;

3. We have a complete range of spare parts, eliminating the hassle of long lead times for ordering parts;

4. We keep up with industry standard updates and provide testing instruments that meet the latest standards in a timely manner.

Technical Parameters

| Parameter | Specification |

|---|---|

| Control System | PLC+ Touch Screen (Man-machine interface control system with easy operation and power-off saving function) |

| Counting | 0——999 999 times, automatic stop function when reaches set amount and setting the insertion and extraction times functions in the man-machine interface |

| Drive Motor | High precision servo motor control, stable speed, lower noise, long life span. The right fixture seat can be controlled to left and right movement and positioning speed and angle is accurate than ordinary cylinder |

| Frequency of the Right Clamp | 25±1/ min |

| Open and Close Cylinders | 2 yadeke cylinders |

| Cushion Hydraulic Cylinder | 2 |

| The Right & Left Clamps | Convenient to adjust the samples under different position. This structure adopts a combination of mechanical and pneumatic design |

| Air Supply | exceeding 6kg/cm² |

| Servo Motor | 400w |

| Power Supply | Single phase, AC220V, 50/60HZ |

Accessoriess

It consists of two sets of sample clamps, left and right. The left sample clamp fixes the upper part of the connector and can periodically press the locking mechanism of the connector (left and right locking or up and down locking); the right sample clamp cooperates with the left one to make the upper and lower parts of the connector move horizontally back and forth, with adjustable movement frequency.

1. Counter: Records the number of opening and closing cycles; one opening and closing cycle counts as one time.

2. Control device: It has an automatic stop function in case of sample abnormality during the test and also has a memory function.

Test Procedures

To ensure the long-term stable operation of the testing machine, the following maintenance procedures should be performed regularly:

1. Accuracy Calibration

Calibrate the equipment annually using calibration weights and a torque wrench, keeping the error within 3%.

2. Cleaning and Maintenance

Cover the machine with a dust cover after each use, regularly clean dust from the drive bearings and guide rails, and perform lubrication maintenance every 9 million cycles.

3. Fixture Replacement

For recycled plastics containing additives or high-temperature flame-retardant materials, calibrate the parameters separately and replace with suitable fixtures.

4. Safety Protection

Ensure the equipment is properly grounded, avoid direct exposure of antibacterial components to ultraviolet light, and prevent changes in material properties from affecting test results.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

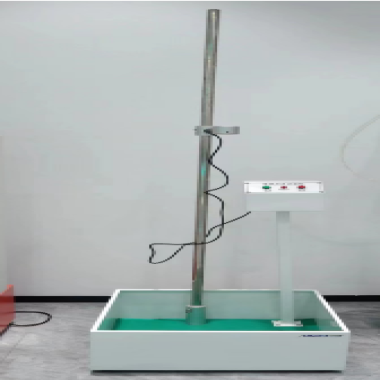

| Falling ball impact testing machine | Product Introduction: Falling ball impact tester is suitable for testing the fastness of plastic, ceramic, acrylic, glass fiber and other material... | |

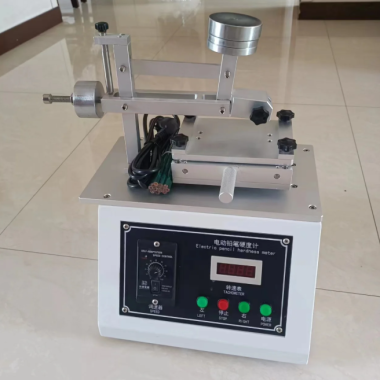

| Electrical Pencil Hardness Testing Device (for Electric pencil hardness tester) | Product Introduction: This machine is suitable for all kinds of finished product spray hardness test, such as: mobile shell, laptop computer shel... | |

| Spray Aerosol Ignition Distance Tester | Product Description Conforms to UN Recommendations on the Transportation of Dangerous Goods - Manual of Tests and Criteria 31.4 Ignition Distance ... | |

| Battery Adiabatic Calorimeter | Battery adiabatic calorimeters play a crucial role in battery research and development, providing essential thermodynamic data for safety assessmen... | |

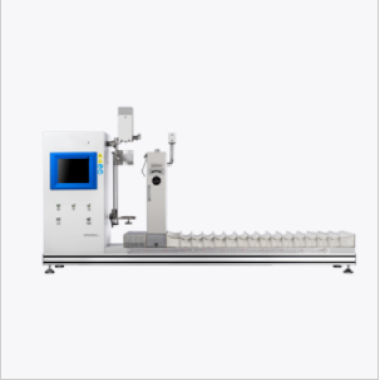

| Sliding Bearing Fatigue Testing Machine | The sliding bearing fatigue testing machine is an important testing device, mainly used to evaluate the fatigue life and performance of sliding b... |

Похожие товары

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Продавец: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Продавец: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Продавец: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Продавец: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |