Incline Impact Tester

The Incline Impact Tester is designed to evaluate the impact resistance of products, packaging, and transport systems under controlled oblique loading conditions. It simulates real-world drop, collision, and tilt scenarios, providing quantitative assessment of structural integrity, energy absorption, and deformation for a wide range of consumer, industrial, and automotive components.

Application

(1) Packaging drop and transport impact testing

(2) Consumer goods durability evaluation under oblique impact

(3) Industrial machinery and palletized freight crash simulation

(4) Automotive component oblique load testing

(5) Quality control in logistics and manufacturing

(6) Material and design validation for R&D laboratories

Standards

(1) ASTM D7748 – Impact resistance testing of packaging and transport systems

(2) ISO 13355 – Automotive component durability evaluation under oblique load conditions

(3) ISTA 3E – Simulates truck collision scenarios for palletized freight testing

Features

(1) Rapid Precision Deployment: Pneumatic positioning system with <0.1 mm repeatability and tool-free impact speed adjustment.

(2) Modular Impact Configuration: Multiple load capacities (1,000–10,000 lbs) and scalable collision surfaces for various product sizes.

(3) Advanced Data Acquisition: High-speed 4-channel TLP system with laser velocimetry for peak force and deformation capture.

(4) Ergonomic Workflow: Low-profile sled and self-centering guides for repeatable impact angles and easy specimen handling.

(5) Industrial Durability: Hardened steel AR500-grade collision plates and IP67-rated sealed drive system for long-term reliability.

(6) Safety Systems: Enclosure interlocks, laser safety curtains, and overload protection to prevent operator hazards.

Parameters

| Model | Load Capacity | Collision Surface | Sled Size | Max Speed | Simulated Drop Height |

|---|---|---|---|---|---|

| Ⅱ1000 | 1,000 lbs | 60” × 60” | 48” × 48” | 8 ft/sec | 18” |

| Ⅱ2000 | 2,000 lbs | 72” × 72” | 60” × 60” | 8 ft/sec | 18” |

| Ⅱ4000 | 4,000 lbs | 84” × 84” | 72” × 72” | 8 ft/sec | 18” |

| Ⅱ6000 | 6,000 lbs | 84” × 84” | 72” × 72” | 8 ft/sec | 18” |

| Ⅱ8000 | 8,000 lbs | 84” × 84” | 72” × 72” | 8 ft/sec | 18” |

| Ⅱ10000 | 10,000 lbs | 96” × 96” | 84” × 84” | 8 ft/sec | 18” |

Accessories

(1) Collision Surface Upgrades: AR600 steel targets, replaceable rubber bumpers

(2) Software Add-Ons: CrashView Pro™ (high-speed video up to 10,000 fps), Cloud Safety remote monitoring

(3) Calibration Services: Annual NVLAP-accredited velocity calibration, accelerometer cross-axis testing

(4) Safety Upgrades: Explosion-proof enclosure, seismic-rated anchoring system

(5) Consumables: High-temperature lubricant for linear bearings, replacement laser sensor covers

Test Procedures

(1) Secure the specimen onto the sled or collision surface using appropriate clamps.

(2) Select load capacity, impact speed, and oblique angle via touchscreen interface.

(3) Initiate pneumatic launcher and monitor real-time force, velocity, and deformation data.

(4) Capture post-impact data and high-speed video for analysis.

(5) Repeat for additional test conditions or specimens as required.

Maintenance Information

(1) Inspect pneumatic components, sled rails, and collision plates regularly for wear.

(2) Clean laser sensors, sled guides, and collision surfaces after each test series.

(3) Verify calibration of velocimetry and accelerometer sensors at scheduled intervals.

(4) Lubricate moving components with high-temperature lubricant.

(5) Store in a dry environment to prevent corrosion and maintain measurement accuracy.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Qinsun Xenotest 220 | Standards ISO 105-B02: Lightfastness testing for colored textiles. AATCC TM16 (Option 3): Accelerated weathering for textiles under controlled co... | |

| Automated Freezing/Pour Point Chiller Tester | Product Introduction: The automatic freezing point pouring point Freezing point tester is suitable for petroleum, biological, chemical and other f... | |

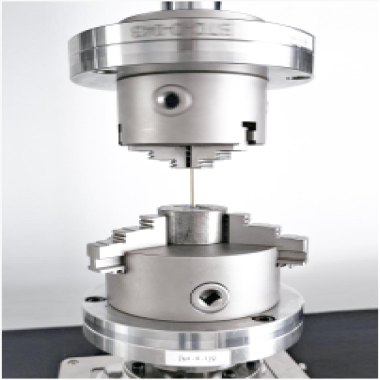

| Safety Helmet Impact Acceleration Tester | The safety helmet impact acceleration tester is an instrument used to test the performance of safety helmets when subjected to impact. It can simul... | |

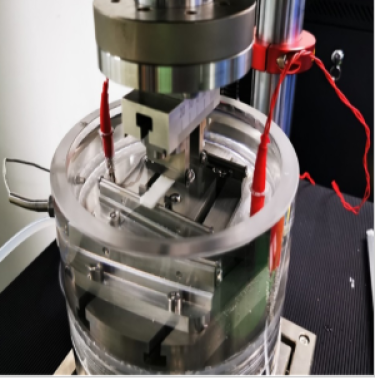

| Spinal Internal Fixation Components System Tester | Standard YY/T 0961-2014 (China): Specifies static/fatigue testing protocols for spinal fixation systems, including connection integrity and anti-l... | |

| Absorbable Bone - connecting Plates Four - point Bending Tester | Standard ASTM F2119: Standard test method for constant load testing of bioabsorbable screws and washers, applicable to bending performance evalu... |

Похожие товары

| Air Permeability Tester STD- F8 | Продавец: Standard International Group (HK) Limited | The Air Permeability Tester is designed to quickly and accurately measure the breathability and p... | |

| Surface Performance Tester STD-FB4 - A | Продавец: Standard International Group (HK) Limited | Introduction TheSurface Tester analyzes finger movements-particularly, strokes-performed by arti... | |

| Compression Tester STD - FB3 - A | Продавец: Standard International Group (HK) Limited | TheCompression Tester analyzes hand movements-particularly, pushing with a finger-performed by ar... | |

| Single - Strand Bending Tester STD - FB2 - SH | Продавец: Standard International Group (HK) Limited | Standards ASTM A370. ASTM A416. ISO6934.4 The Single Fiber Bending Tester makes it possible to ... | |

| Bending Tester STD- FB2 - S | Продавец: Standard International Group (HK) Limited | Compliance Standards ASTM D790 (Plastics Flexural Properties) ISO 178 (Flexural Strength of Rig... |