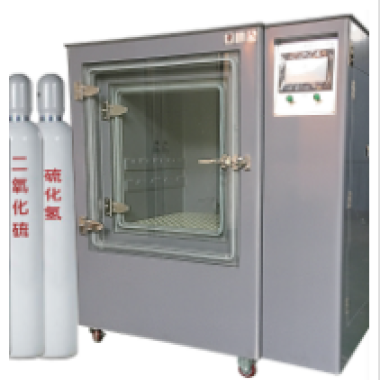

Hydrogen Sulfide Corrosion Test Chamber

The Hydrogen Sulfide Corrosion Test Chamber is a precision environmental testing instrument designed to evaluate the corrosion resistance of metals, coatings, and chemical-treated surfaces under controlled hydrogen sulfide (H₂S) gas conditions. It provides accurate control of temperature, humidity, and H₂S concentration, allowing simulation of corrosive environments to assess material durability, color change, and coating performance.

Application

(1) Testing corrosion resistance of metal and non-metal coatings.

(2) Evaluating color change resistance of metal plating and chemical treatment layers.

(3) Assessing durability of electrical products and components exposed to H₂S gas.

(4) Material quality control in automotive, aerospace, and industrial manufacturing.

(5) Research and development of protective coatings and corrosion-resistant materials.

(6) Certification and compliance testing for domestic and international standards.

(7) Laboratory evaluation of alloys, steels, copper, zinc, nickel, and painted or plated surfaces.

Standards

(1) GB/T 978.9-88 – Corrosion Test of Metal and Non-Metal Coatings Under Condensing Sulfur Dioxide.

(2) ISO 6988 – Corrosion Tests in Artificial Atmospheres – Sulfur Dioxide Tests.

(3) QB/T 3831 – Color Change Resistance Test for Metal Plating and Chemical Treatment Layers.

(4) GB 2423.20-81 – Hydrogen Sulfide Test for Electrical Products.

(5) Additional international and national standards for gas corrosion, environmental simulation, and accelerated aging tests.

Features

(1) High-precision PID microcomputer controller with 0.1°C resolution.

(2) Stable temperature control: ±0.5°C or ±2°C depending on model.

(3) Bottled gas supply system with precise H₂S concentration regulation (0.1–1% v/v).

(4) Humidity control: 93–98% RH with ±2% deviation.

(5) Titanium alloy nickel-chromium heating system with PID+SRR synchronization.

(6) Safety protections including leak detection, short-circuit protection, and over-temperature protection.

(7) Equipped with 6 V-shaped corrosion-resistant racks and 12 O-shaped test rods.

(8) Robust rotary table system allowing simultaneous testing of multiple samples.

Technical Parameters

| Model | Inner Chamber Size (W×D×H) | Outer Dimensions (L×W×H) | Power Consumption (kW) | Temperature Range | Humidity Range | Gas Concentration |

|---|---|---|---|---|---|---|

| H2S-150 | 450×600×450 mm | 680×1000×1050 mm | 1.1 | 25–40°C | 93–98% RH | 25±5 ppm |

| H2S-250 | 600×900×500 mm | 850×1420×1120 mm | 1.2 | 25–40°C | 93–98% RH | 25±5 ppm |

| H2S-750 | 750×1100×500 mm | 1000×1650×1320 mm | 2.1 | 25–40°C | 93–98% RH | 25±5 ppm |

| H2S-010 | 850×1300×550 mm | 1150×1900×1370 mm | 2.2 | 25–40°C | 93–98% RH | 25±5 ppm |

Accessories

(1) Gas regulators and safety valves.

(2) Sample holders: 6 V-shaped racks, 12 O-shaped test rods.

(3) Power cable and grounding cable.

(4) User manual and product qualification certificate.

(5) Optional data logging and timer extension modules.

Test Procedures

(1) Place test samples onto V-shaped racks or O-shaped rods.

(2) Insert the sample holders into the rotary table and secure the chamber.

(3) Set target temperature, humidity, and H₂S concentration on the controller.

(4) Activate fan rotation for uniform gas distribution across all samples.

(5) Run the test for the designated duration according to the selected standard.

(6) Record weight changes, color change, or corrosion effects after exposure.

(7) Repeat testing for multiple cycles or comparative studies as needed.

Maintenance Information

(1) Regularly inspect gas supply system and valves for leaks.

(2) Calibrate temperature and humidity sensors periodically.

(3) Clean chamber interior and sample holders to prevent residue build-up.

(4) Verify fan operation and rotary mechanism to ensure uniform gas distribution.

(5) Store the instrument in a dry environment and avoid direct sunlight exposure.

(6) Check electrical components, PID controller, and safety interlocks before each use.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Suture Needle Cutting Force Tester | The Suture Needle Cutting Force Tester is a precision instrument specifically used to detect the force required by medical suture needles during th... | |

| Carpet Dynamic Load Tester | Compliance Standards ISO 2094: 1999 (BS) QB/T 1091-2001 ASTM D3574 TEST I4 Instrument Features Provide information on the reduction in the thi... | |

| Minimum Ignition Energy (MIE) – Dust Cloud Tester | Dust Cloud Minimum Ignition Energy Tester disperses a certain mass of dust specimen to be tested into the Hartmann tube device through a certain pr... | |

| Textile Thermal Insulation Property Tester | Standard GB/T 41560-2022 (China): Specifies thermal resistance testing protocols for protective clothing and industrial fabrics. BS 6526:1998 (... | |

| Metal Corrosivity Tester | The Metal Corrosivity Tester is used to determine the corrosivity of liquids and solids that may become liquid during transport. It conforms to the... |

Похожие товары

| Full-Body Garment Stress Tester,FZ/T 70015 | Продавец: Standard International Group (HK) Limited | TheFull-Body Garment Stress Testeris a precision instrument designed to quantify the pressure exe... | |

| Industrial Dry Cleaning Machine,industrial garment steamer | Продавец: Standard International Group (HK) Limited | TheIndustrial Dry Cleaning and Energy-Saving Dryer Machinesare designed for high-performance, rel... | |

| MST Medical Compression Stocking Tester,compression sock tester | Продавец: Standard International Group (HK) Limited | The MST Medical Compression Stocking Tester is a professional instrument designed to evaluate the... | |

| MMT Liquid Water Separation Tester,MMT Liquid Water Analysis Tool | Продавец: Standard International Group (HK) Limited | Applications Textile Manufacturing:Testing waterproof fabrics for outdoor gear R&D:Developi... | |

| Dental material color stability tester | Продавец: Standard International Group (HK) Limited | Application The applications of color stability testers for dental materials are mainly reflecte... |