Supporting Roller

CIC is a more than 30 years manufacturer and reputed supplier of support roller used in rotary kilns, rotary type driers and so on. CIC has been specialized in designing, producing whole set of rotary machinery, so also has rich experience in supplying support device, such as support roller, support roller assembly and so on. CIC possesses professional design teams, advanced equipments and detecting method, strict quality control system to meet all your customized requirements of support roller. High quality, excellent performances and competitive price will make you rely on us and choose us. CIC has manufactured spheroidal cast iron supporting rollerwith max. diameter 1.5m, and high quality alloy steel support roller of max. diameter 2.1m.

Feature of Supporting Roller

Material: spheroidal cast iron, cast steel, forged steel and as your requests.

Standard: ANSI, API, ASTM, BSI, DIN, GB, ISO, JIS and more standards.

Mechanical Properties: customized requirements are accepted.

Hardness: customized requirements are accepted.

Surface treatment: rust preventive oil and according to your requirements.

Application: mainly used for supporting devices of rotary kilns, rotary type driers and so on.

QA and DOC: chemical composition report, mechanical properties report, sphere iodization rate report, UT report, PT report, heat treatment report, dimensions check report, hardness report and more.

We can offer third-party inspection.

Process: raw material purchasing - casting- rough machining - heat treatment - semi machining - finish machining - shrinkage fitting - painting and packing.

Various process conditions are available.

Certificates: ISO 9001:2008.

Products ability: Max OD: 2.5m.

Heat treatment: quenching and tempering, normalizing and tempering.

QC: fabrication schedule, fabrication process chart, inspection and test plan.

Packing: coated with rust preventive oil, wood- steel frame, seaworthy packing.

Our Advantage of Supporting Roller

More than 30 years of experience

ISO 9001:2008 Standard certified

Custom-made design

Strict quality control

Prompt delivery

More wearable

Lower noise

Longer service life

Technical Parameter of Supporting Roller

|

Name |

Supporting Roller |

|

Material |

Spheroidal Cast Iron |

|

Chemical Composition |

C: 3.08~3.30, Si: 2.49~3.13, Mn: 0.55~0.61, S: 0.017~0.022, P: 0.045~0.052 |

|

Spheroidal Rate |

≥90% |

|

Hardness Value |

HB 265~300 |

|

Mechanical Properties |

Tensile Strength: ≥720N/mm2, Yield Strength: ≥420N/mm2, Elongation: ≥2% |

Package and Delivery of Supporting Roller

Careful and safe packaging ensures that your products arrive at the customer site smoothly.

There are many cement machinery suppliers, but we are one of the best choices for you.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Rotary Kiln | CIC’s equipment includes leading standardized heavy equipment and machinery products and related heavy machinery services, which can be sold ... | |

| Vertical Centrifuge | Vertical Centrifuge The vertical centrifuge machineis made up of the screen which diameter range from 700 to 1,000 mm , the rotor body (including ... | |

| CIC Customized Cement Grinding Mill and Rotary Kiln for Cement | As a kind of building material, cement is widely used with large demand and fierce competition in the industry. As the leader of cement production... | |

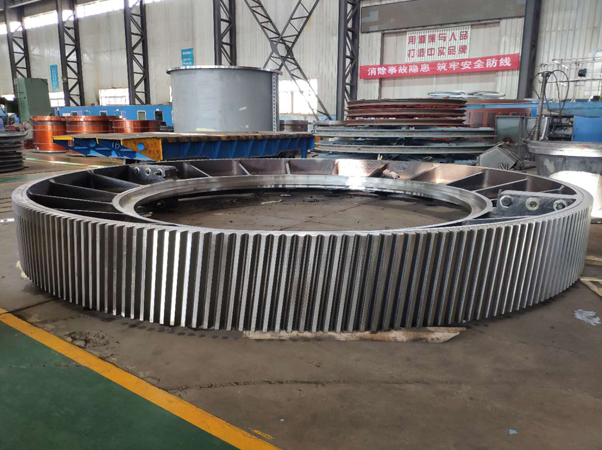

| Girth Gear | CIC is the casting & forging center in central-south China, possessing a 50t electric arc furnace, 60t LF ladle refining furnace, and 60t VD/VO... | |

| Calcium Carbide Furnace Tap Hole Machine | Dig furnace robot arm controlhas a walking mechanism, multi-station operator, hydraulic, electronic control, and other components. The operation is... |

Похожие товары

| Supporting Roller | Продавец: CITIC IC LUOYANG HEAVY MACHINERY CO., LTD | CIC is a more than 30 years manufacturer and reputed supplier of support roller used in rotary ki... |