High Precision durable Right vertical milling head

1, TX series milling head TX series milling head is a general power parts, it is equipped with a milling table or power slide supporting a variety of supporting parts can be composed of various forms of combination milling machine. Milling head to use the teeth face milling cutter As the basis, can also use a smaller diameter of the dense tooth end milling cutter for steel, cast iron, non-ferrous metals and other parts of the material for surface milling; installation of auxiliary tool table, but also to complete milling, milling and other processes.

This series of milling head for steel, cast iron and non-ferrous metal parts of the plane milling, milling and other processes. Common-level precision milling head for rough milling, the use of dense tooth end mills can be a strong knife strong milling. High-precision (G) milling head for high-precision milling, the maximum feed speed up to 2500mm / min. Maximum processing accuracy: flatness 0.01 ~ 0.03 / 1000, surface roughness ≤ 0.4. The milling head is divided into: I type (manual movement and tightening sliding sleeve); II type (with hydraulic automatic knife mechanism).

Milling head with four kinds of transmission: belt drive, spindle speed is higher for non-ferrous metal processing; tail-type transmission, mainly for vertical configuration type; handle variable speed transmission device, suitable for changing the cutting speed Requirements; overhead transmission. Wide range of applications.

2, TA series boring head

TA series boring head in line with JB1531-75 combination machine common parts - boring head standard requirements, widely used in combination machine tools and automatic machine tool line. This series of boring head and the same specifications of the hydraulic slide or mechanical sliding table supporting the composition of boring machine combination, to complete the cast iron, steel and non-ferrous metal parts of the uniaxial rigid rough, fine boring process.

This series of boring head and the same specifications of the hydraulic slide or mechanical sliding table supporting the composition of boring machine combination, to complete the cast iron, steel and non-ferrous metal parts of the uniaxial rigid rough, fine boring process. Highest Boring Accuracy IT7. The optimum roughness of the machined surface is 1.6. Special order is available for manual speed change.

3, TD series power box

TD series power box This series of power box for the gear drive power source components, it is compatible with the spindle box to achieve the main movement of the machine, mainly for multi-axis box with a combination of machine tools and automatic lines.

This series of power box for the gear drive power source components, which with the spindle box to achieve the main movement of the machine, mainly for multi-axis box with a combination of machine tools and automatic lines.

4, HJ series of mechanical slide

HJ series of mechanical slide for the feed movement, horizontal can also be used vertically, in the mechanical slide to install power box (equipped with multi-axle box). Drilling head, boring head, milling head, boring head and other components, to complete the drilling, expansion, hinge, boring, counters nest nest. Scraping face, chamfering, car face, milling and tapping and other processes.

Mechanical slide table for the feed movement, horizontal can also be used vertically, in the mechanical slide to install the power box (fitted with multi-axle box). Drilling head, boring head, milling head, boring head and other components, to complete the drilling, expansion, hinge, boring, counters nest nest. Scraping face, chamfering, car face, milling and tapping and other processes. Table width of 320 mm below the mechanical slide, if the installation of grading feed device, you can also complete drilling deep hole process.

Slide table according to the length of travel, divided into Ⅰ, Ⅱ, Ⅲ, Ⅳ type, according to different specifications divided into 250,400,630, l000,1600 mm. Users can choose according to need, order must indicate the length of travel. When the slide for deep hole machining, should also indicate with a graded feed device.

Другие товары поставщика

|

|

Large CNC double - headed milling machine manufacturer |

Double-headed milling machines are one of the most widely used milling machines in machinery manufacturing and assembly plants, and the difference ... |

|

|

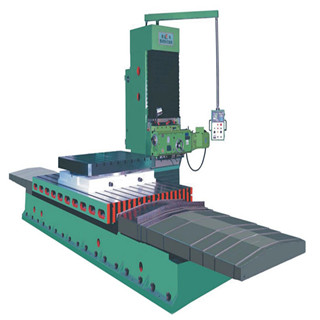

High Precision stable durable alloy steel horizontal milling machine supplier |

1, machine rigidity is good, can carry heavy load cutting. 2, horizontal milling machine spindle motor power, variable speed range, give full play ... |

|

|

High Precision durable Right vertical milling head |

1, TX series milling head TX series milling head is a general power parts, it is equipped with a milling table or power slide supporting a variety ... |

|

|

Large High Quality CNC gantry grinder manufacturer |

Gantry grinder as a whole for the gantry layout, bed, column, beam composed of a rigid frame structure (table double-layer structure), gantry grind... |

|

|

Strong carrying capacity Large CNC Horizontal Milling Machine |

1. Spindle sleeve can be manually micro-feed, and set the limit device, milling head can be followed, counterclockwise rotation adjustment 45 °... |

Все товары поставщика

Похожие товары