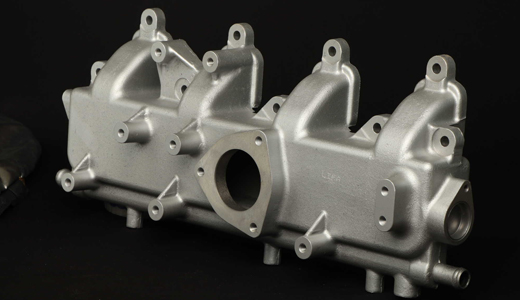

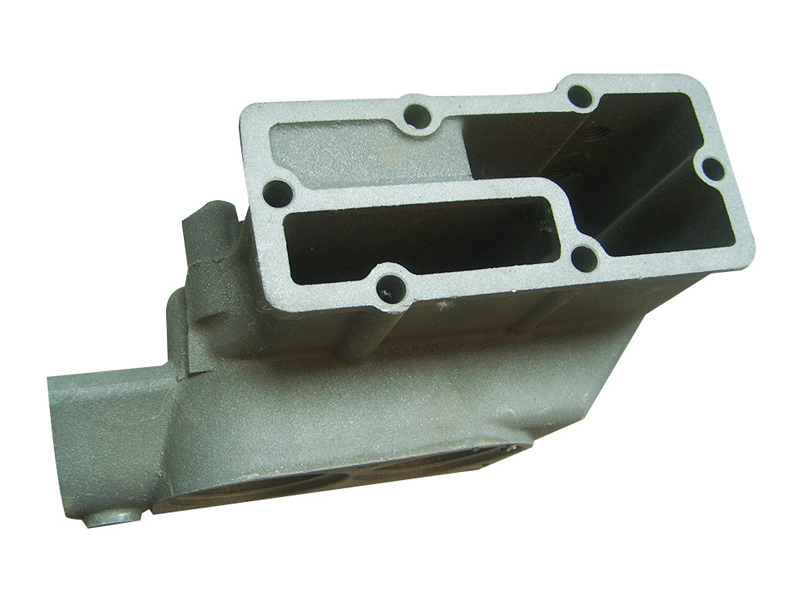

Silica Sol Investment Casting

The silica sol also shares the name of water glass in general, it is used by the meatal casting process as mold adhesive which is mixed with sand and several other materials. The silica sol is applied to both sand casting and investment casting technics. It is one of the most common investment casting processes. As the molding material, silica sol is able to stand temperature up to 1800℃. Similar to other investment casting processes, the silica sol investment castingprocess mainly consisted of wax injection, assembly, shell preparation, dewax, pouring, cut-off, and finished casting, etc.

Compared to the resin investment casting, the silica sol method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. The surface quality is not as good as the resin casting, but it's cheaper and a bigger-sized part could be manufactured than silica sol casting.

Application of Silica Sol Casting

Mainly the silica sol is applying to the precision casting, because of its relatively high production cost but gives out a very fine accurate dimension, nice surface finish, and very good quality result overall. One of the other advantages for silica sol is that the internal defects such as porosity, holes, shrinkage are better controlled compared to another way of casting. So when you looking for a method to produce a small part but with high accuracy, surface demand, high corrosion resistance and you don't want to waste time waiting for the casting quality in slow improved gradually, silica sol investment casting is surely on your options list.

The Basic Property of the Product Made by Silica Sol Casting:

dimension tolerance ±0.1mm, CT4~6;

surface finish Ra6.3;

wall thickness up to 1mm;

unit weight extent 0.1~100kg;

unit size limitation 0.01~0.5 meter;

degree of complexity- very complex;

machining required- less or none due to its accurate dimension;

production lead time- long;

production cost- high;

Influence Factor in Silica Sol Investment Casting

The whole casting process has more than 40 procedures, the process is complex, and there are many process factors that affect the casting quality.

There are many kinds of raw and auxiliary materials, such as silica sol, wax, zircon sand, molybdenum powder, defoamer, wetting agent, steel, rare metal, etc. According to the different mesh, there are more than 10 kinds of sols, including precision casting surface silica sol, precision casting backside silica sol, ordinary silica sol, enhanced silica sol, fast-drying silica sol, and zirconia powder. It is not suitable to control its quality, which affects the casting quality in different degrees.

The production cycle is long and there are many uncontrollable factors. In the whole process, only the shell-making process takes 3-5 days. It takes 6-8 hours to dry the surface shell of silica sol, 4-6 layers to dry the back shell of silica sol, and 8-12 hours to dry the shell without silica sol. There are too many uncontrollable factors and defects will be formed with slight deviations in the process operation.

Rayforce Manufacture is a privatemetal casting supplier, we provide metal casting china, vacuum die casting and etc. Want to know more? Please contact us.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| Sand Casting | Sand casting is the most commonly applied method for casting the metal part. It suits most of the raw materials, ferroalloy, and non-ferroalloy bot... | |

| Compressors & Gears | Rayforce's metal die casting gearscan be applied to Turbo blowers, air control components, piston compressors, casting gears, etc. Application o... | |

| Die casting | Die Casting involves 3 key elements: the die casting machine, the mold, and the alloy materials, and the die casting could be described as the proc... | |

| Investment Casting | Investment casting, also called the lost-wax casting process, is actually an ancient metal casting technology with a history of over 6,000 years. I... | |

| Green Sand Casting | Sand casting means the main material consisting of the mold is sand, and the melted metal fills the casting cavity only by its gravity. Generally, ... |

Похожие товары

| Industrial 3-Piece Stainless Steel Valve Parts | Продавец: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Продавец: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Инжекционная машина для керамических стержней | Продавец: Qinhuangdao Aifu Science & Technology Co., Ltd. | Инжекционная машина для керамических стержней является основным оборудованием для производства вы... | |

| Одностанционный восковой инжектор | Продавец: Qinhuangdao Aifu Science & Technology Co., Ltd. | Восковой инжектор используется для производства восковых форм в производственной линии для точног... | |

| Автоклав для удаления воска | Продавец: Qinhuangdao Aifu Science & Technology Co., Ltd. | Автоклав для удаления воска является специализированной машиной для удаления воска в технологичес... |