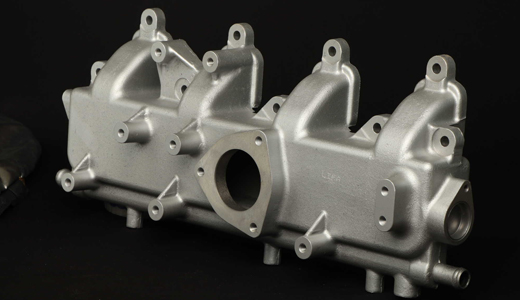

Silica Sol Investment Casting

The silica sol also shares the name of water glass in general, it is used by the meatal casting process as mold adhesive which is mixed with sand and several other materials. The silica sol is applied to both sand casting and investment casting technics. It is one of the most common investment casting processes. As the molding material, silica sol is able to stand temperature up to 1800℃. Similar to other investment casting processes, the silica sol investment castingprocess mainly consisted of wax injection, assembly, shell preparation, dewax, pouring, cut-off, and finished casting, etc.

Compared to the resin investment casting, the silica sol method dewaxes into the high-temperature water, and the ceramic mold is made of water glass quartz sand. The surface quality is not as good as the resin casting, but it's cheaper and a bigger-sized part could be manufactured than silica sol casting.

Application of Silica Sol Casting

Mainly the silica sol is applying to the precision casting, because of its relatively high production cost but gives out a very fine accurate dimension, nice surface finish, and very good quality result overall. One of the other advantages for silica sol is that the internal defects such as porosity, holes, shrinkage are better controlled compared to another way of casting. So when you looking for a method to produce a small part but with high accuracy, surface demand, high corrosion resistance and you don't want to waste time waiting for the casting quality in slow improved gradually, silica sol investment casting is surely on your options list.

The Basic Property of the Product Made by Silica Sol Casting:

dimension tolerance ±0.1mm, CT4~6;

surface finish Ra6.3;

wall thickness up to 1mm;

unit weight extent 0.1~100kg;

unit size limitation 0.01~0.5 meter;

degree of complexity- very complex;

machining required- less or none due to its accurate dimension;

production lead time- long;

production cost- high;

Influence Factor in Silica Sol Investment Casting

The whole casting process has more than 40 procedures, the process is complex, and there are many process factors that affect the casting quality.

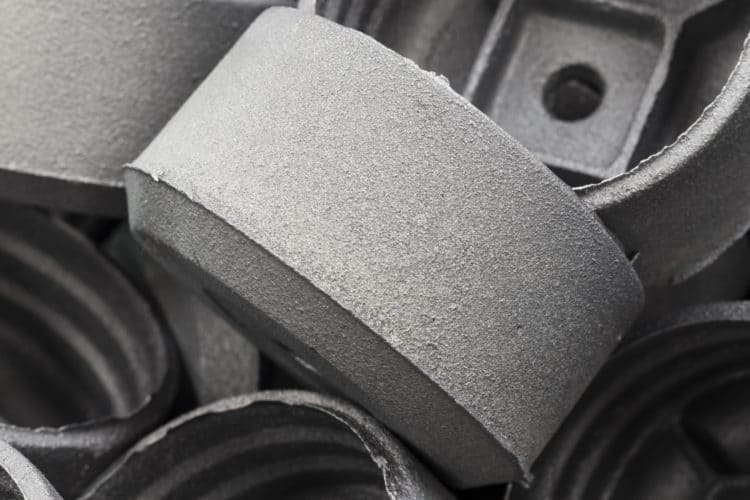

There are many kinds of raw and auxiliary materials, such as silica sol, wax, zircon sand, molybdenum powder, defoamer, wetting agent, steel, rare metal, etc. According to the different mesh, there are more than 10 kinds of sols, including precision casting surface silica sol, precision casting backside silica sol, ordinary silica sol, enhanced silica sol, fast-drying silica sol, and zirconia powder. It is not suitable to control its quality, which affects the casting quality in different degrees.

The production cycle is long and there are many uncontrollable factors. In the whole process, only the shell-making process takes 3-5 days. It takes 6-8 hours to dry the surface shell of silica sol, 4-6 layers to dry the back shell of silica sol, and 8-12 hours to dry the shell without silica sol. There are too many uncontrollable factors and defects will be formed with slight deviations in the process operation.

Rayforce Manufacture is a privatemetal casting supplier, we provide metal casting china, vacuum die casting and etc. Want to know more? Please contact us.

Send product request

Other supplier products

| Stainless Steel Investment Casting | The stainless steel has much better physical properties then iron and normal steel, but it possesses worse casting properties. Because the stainles... | |

| Grey Cast Iron Casting | The name grey iron is because of the gray color of the fracture it forms, which is due to the presence of graphite. Grey iron is the most common an... | |

| Brass, Bronze, Copper Casting | As defined by its main properties, copper offers excellent electrical and heat conductivity, and good corrosion resistance ability as well. But nat... | |

| Lost Wax Investment Casting | Lost Wax Investment Casting The lost wax casting aluminumprocess can differ depending on the application and the requirement, but it generally con... | |

| Lost Wax Investment Casting | The lost-wax casting process can differ depending on the application and the requirement, but it generally consists the following steps: Molde-maki... |

Same products

| Industrial 3-Piece Stainless Steel Valve Parts | Seller: Qingtian Baoli Casting Co., Ltd. | Industrial 3-Piece Stainless Steel Valve Partsare manufactured for use in pipelines and process s... | |

| METAL BRACKETS | Seller: JCL Precision Part Co.Ltd. | Custom metal brackets are some of the strongest supports. JCL precision-engineers them to your cu... | |

| Ceramic Core Injector | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Ceramic Core Injector is designedspecifically for producingcomplex, high quality and high pre... | |

| Wax Injection Machine | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | The Wax Injection Machine is used to make wax patterns in the investment casting process with mid... | |

| Automatic Dewaxing Autoclave | Seller: Qinhuangdao Aifu Science & Technology Co., Ltd. | Dewaxing Autoclave is specially designed for removing the wax patterns in the ceramic shell. Ins... |