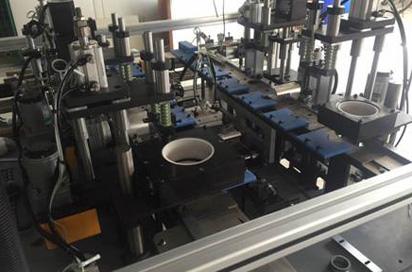

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all defects.

The cause of the cracks in the bearing rings is complicated. From the raw materials to the finished products of the ferrules, if the process is not proper, the cracks may be directly caused or the hidden cracks may be buried for the occurrence of the lap ring grinding cracks.

There are many ways to form cracks in bearing rings: Raw material defects include: cracks in raw materials and the effects of raw material defects on the grinding process.

Forging defects include forging cracks, effects of forged microstructure defects on the grinding process, and cutter cracks. There are also various heat treatment defects and the like. Therefore, crack detection and hardness testing are essential. BKN has considerable experience in crack detection, and Bearing Ring Crack and Hardness Combination crack testing equipmentis a perfect combination.

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 Brief Introduction

Detection process

Vibrating plate and string charging →hardness test→crack detection→automatic blanking

↓

Bad product sorting

Automatic charging —automatic detection—automatic sorting —automatic blanking

Charging mechanism

Hardness testing

Crack detection(the probe uses stainless steel casing+nano abrasion material ) to ensure long-term normal of the probe

Discharging sequencing mechanism

Crack sensitivity: a crack with a depth of ≥0.05 mm and a length of ≥1 mm extending inward from the surface of the ferrule; for a crack that has not extended to the surface inside the ferrule, when the thickness between the subcutaneous surface and the surface of the workpiece is ≤0.2 mm, the depth is ≥0.20 mm Cracks of length ≥ 1 mm can be detected.

Hardness sensitivity: Rockwell 1HRC ~ 2HRC (other parameters remain stable and consistent).

As one of non destructive testing equipment suppliers, we can offer sorts of ndt testingmachines for sale, anything you need, please leave us a message.

Отправить запрос, связаться с поставщиком

Другие товары поставщика

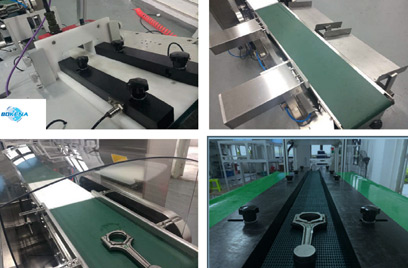

| Connecting rod hardness eddy current sorting machine LGYDFX-01 | The connecting rod hardness eddy current sorting machinehas a calibration device, input compensation parameters, automatic/manual temperature compe... | |

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| Eddy Current Testing Equipment | Electromagnetic detection is a very important non-destructive testing method and is widely used. Magnetic flux leakage testingis a magnetic method ... | |

| Eddy Current Testing Equipment | ECT Eddy current testingis a non-contact testing method, which mainly uses the electromagnetic field and electromagnetic induction between metals t... | |

| Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 | During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all d... |

Похожие товары

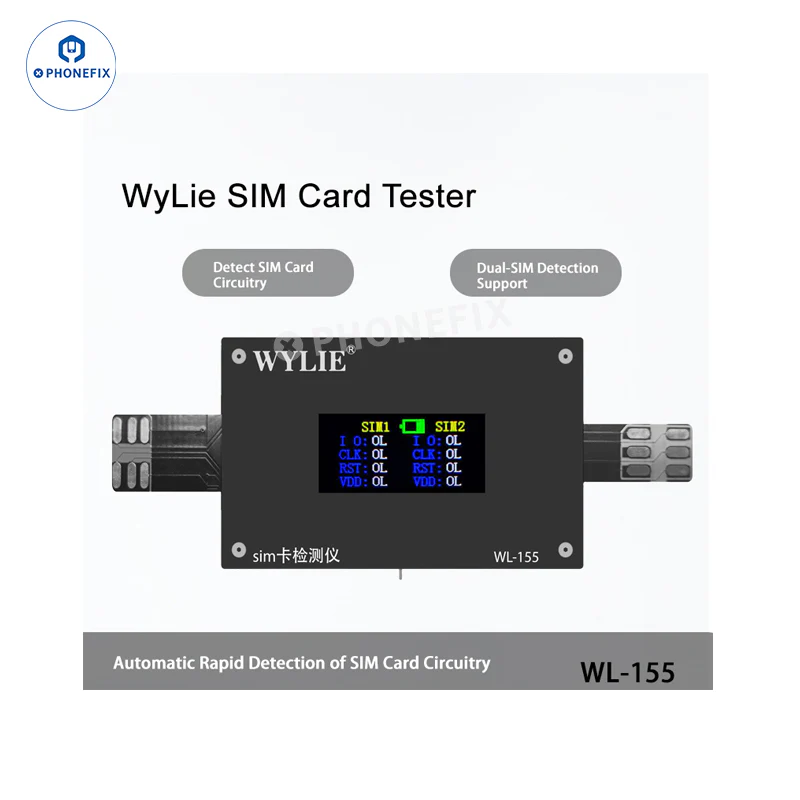

| WYLIE WL-155 SIM Card Tester for iPhone 14-17 Pro Max & Android | Продавец: China PHONEFIX Technology Co., Ltd | Тестер SIM-карт WYLIE WL-155 используется для обнаружения цепей SIM-карт и поддерживает обнаружен... | |

| Высокоточный датчик напряжения HCV1500 | Продавец: Shenzhen Hangzhi Precision Electronics Co., Ltd | Высокоточный датчик напряжения HCV1500 — это датчик напряжения, способный измерять постоянн... | |

| Xenon Test Chamber | Продавец: Standard International Group (HK) Limited | Features and Benefits 1.The use of xenon arc lamp as a light source, can simulate the full sunli... | |

| Single Cable Vertical Flame Tester | Продавец: Qinsun Instruments Co., LTD | Introduction Single Cable Vertical Flame Tester is used for the vertical flame propagation of a ... | |

| Safety Helmet Flammability Tester | Продавец: Qinsun Instruments Co., LTD | Product Introduction: Safety hat flame retardant performance tester for safety hat flame retarda... |