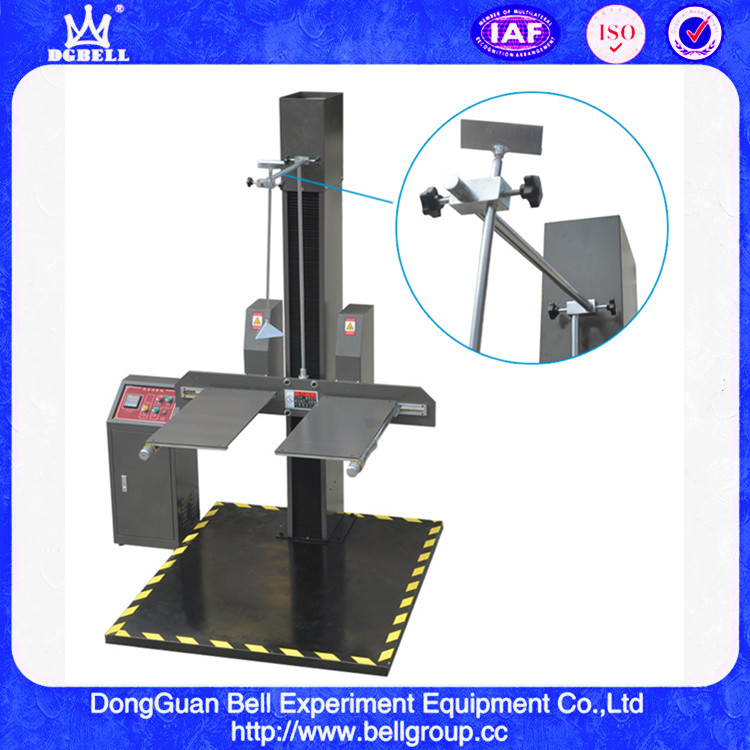

Double Wings Package Drop Impact Tester Drop Testing Machine BF F 415D

Applications

Drop Impact Test machineis to test large and heavy package products’ drop impact performance

throughsimulate real face ,edge and corner drop conditions. This equipment mainly used toinspect package products drop resistance capability during transportation ,load and unload works, thus help improve the package design.

Testing Principle

Specimen automatically lifting to pre-setting height, then free drop and shock on the drop plate.

Standard Compliance

ISO 2248 ,

GB/T4857.5-92

Features

1 This machine available for package face, corner, edge free drop testing.

2 With height digital display instrument and tracing height with encoder, so can measure the precision drop height.

3 The drop height tolerance within2% or 10mm;

4 This machine with single wing double column structure, with electronic return, electric control dropping and electronic lifting & dropping devices, easy for operation.

5 Particular impact attenuation device largely increased the machine service life, stability and safety.

6 Drop angle impact surface and bottom plane angle less than 5º;

7 Bottom base with enough weight and thrust surfacearea, ensure 70kg loading from 1.5 meters height, machinewith no tilt, no shake when testing, thus makes the specimen with free dropping.

Technical Parameters

|

Drop Height |

400~1500mm(digital display, controllable) |

|

Testing Method |

Face, edge, corner dropping |

|

Test Loading |

0~70kg |

|

Specimen Max. Dimension |

W1000 x D800 x H800mm |

|

Drop Plate Dimension |

W1200 x D1700 x H40mm(core plate) |

|

Machine weight |

About 750kg |

|

Machine dimension |

W1200 x D1700 x H2400mm |

|

Controller Dimension |

W270 x D270 x H1150mm |

|

Motor Power |

0.75KW |

|

Power Source |

3PH 4wires+grounding wire ,380V 50Hz |

|

Others |

With impact attenuation device, encoder precisely set the height. |

Testing Procedure

1 Fix the specimen on the drop arm, lift to the certain drop height, only±2% difference allowed between the height and setting value. Drop height refers to the distance between the lowest point when release the specimen and the shock impact plate.

2. Release the specimen according to below predetermined state:

A.Face dropping, the angle between the specimen drop face and flat plane should within 2º;

B.Edge dropping, the angle between the edge and the flat plane within 2º,the angle between upper face of specimen and shock plate within±5ºor 10% of angle(Whichever is the larger value),ensure the specimen gravity line through the dropping edge.

C.Corner dropping, the angle tolerance between the specimen upper face and shock impact plate less than or 10% of the angle(Whichever is the larger value),ensure the specimen gravity line through the dropping corner..,

D. No matter what kind shape or status of the specimen, all have to ensure the gravity line of the specimen through the dropping face, edge and corner.

3 The difference between the actual shock speed and the speed when free dropping should within±1% .

4 After testing, check the package and inner products damage condition according to related standard or regulations. And analyze the testing result.

Notice

1 Suggest to put this machine on first floor because of the large volume, and weight about 750kg, normal elevator can not enter in, un-easy for moving.

2 Pay attention to safety when do dropping test, do not close to the shock plate when specimen dropping, avoid injuries caused by specimen dropping or arm return, and influence of the testing results.

3 This machine need regular maintenance to longer the machine service life

Отправить запрос, связаться с поставщиком

Другие товары поставщика

| UL1642 Battery Squeeze Machine Nail penetration Testing BE 6047 | Application To test battery safety performance by crushing & nail-penetration through real-time test data ( battery voltage, max. battery tempe... | |

| Comprehensive Lithium Battery Safety Performance Testing System BE-JKXT-08 | 1. Introduction Integral Battery safety control system is mainly appliedto test battery performanceswhen batteryin hazard environment or damaged ex... | |

| Tensile Test Machine 5KNS | Application This equipment is designed and manufactured tomeasure & test tensile strength, compression strength, peeling strength, tearing... | |

| High Low Temperature/ Alititude Test Chamber BTHQ series--Standard Vacuum Chamber | Applications This equipment is widely applied for aviation, communication ,electronic etc. industries, instruments and meters ,electric products, m... | |

| Double Wings Package Drop Impact Tester Drop Testing Machine BF F 415D | Applications Drop Impact Test machineis to test large and heavy package products’ drop impact performance throughsimulate real face ,edge and... |

Похожие товары

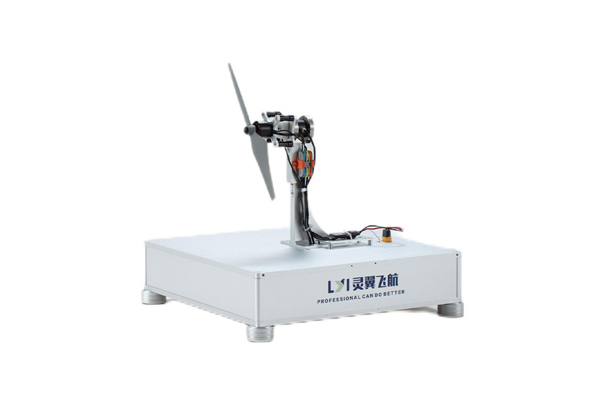

| WF-EDU-02 Motor & Propeller Test Kit | Продавец: Wing Flying Technologies Co., Ltd | WF-EDU-02 Motor & Propeller Test Kit Product Description Motor & Propeller Test Kitsare... | |

| WF-EDU-01 Motor and Propeller Test Kit | Продавец: Wing Flying Technologies Co., Ltd | WF-EDU-01 Motor and Propeller Test Kit Product Description Suggested Propulsion system ... | |

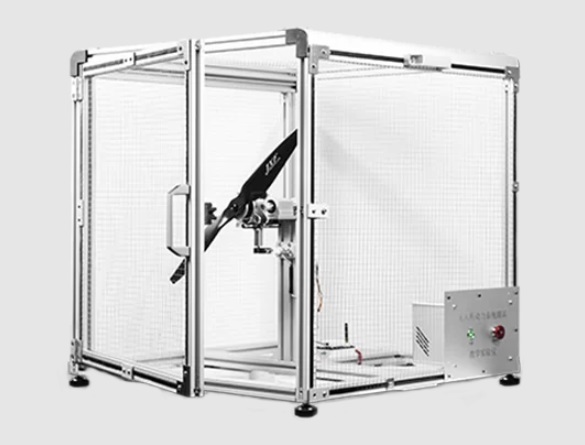

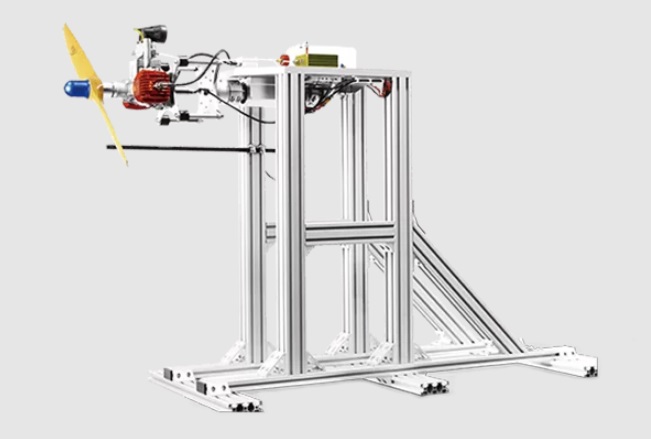

| WF-EN-50 Engine Test Bench | Продавец: Wing Flying Technologies Co., Ltd | Suggested Engine 110cc-350cc Engine Max Hanging Type Engine 20kg ... | |

| WF-EN-15 Engine Test Bench | Продавец: Wing Flying Technologies Co., Ltd | WF-EN-15 Engine Test Bench Product Description Suggested Engine 110cc Engine ... | |

| BS EN 12600 Two Tyres Impactor | Продавец: Qinhuangdao Yuanchen Technology Equipment Co., Ltd. | Reference Standard: BS EN 12600:2002Glass in building – Pendulum test – Impact test m... |