high quality Mo-30W Mo-50W Mo-85W Tungsten-molybdenum Alloy

The melting point of tungsten-molybdenum alloy is improved along with the increase of tungsten content. When the tungsten content is increased to 25%, the melting point of the alloy is about 200℃ higher than that of pure molybdenum. Therefore, corresponding alloy components can be selected at the temperature of 2,620~3,410℃ according to the operating temperature and the required alloy melting point. This advantage is also one of advantages that enable molybdenum-tungsten alloy to be used relatively widely. The lattice constant and density of molybdenum-tungsten alloy are improved according to linear functions along with the increase of the tungsten content. The hardness and strength of tungsten-molybdenum alloy are basically improved along with the increase of the tungsten content. The highest hardness value of the alloy at room temperature is 90%~100% of the tungsten content, and its Vickers hardness value is up to 3,530~3,860MPa which is more than one time that of pure molybdenum. The highest hardness value of the alloy at high temperature is 70%~85% of the tungsten content. When the tungsten content is increased from 0 to 40%, the tensile strength of molybdenum-tungsten alloy at room temperature in the processing state is increased from 617MPa to 900MPa. The nominal compositions of frequently used molybdenum-tungsten alloy include Mo-30W, Mo-50W, Mo-85W, etc

Другие товары поставщика

|

|

good conductor of electricity and heat stable chemical properties Tungsten Carbide |

Chemical formula: WC. Black hexagonal crystal, metal luster, high hardness similar to that of diamond, good conductor of electricity and heat. Melt... |

|

|

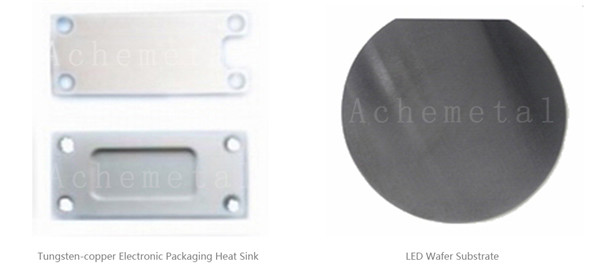

Heat Sink Material stable operating temperature |

With the development of electronic technologies, the heating of components has increasingly become a bottleneck of their functions and service life... |

|

|

High-specific-gravity higher mechanical property Tungsten Heavy Alloys with 80%~98% tungsten |

Tungsten heavy alloys material formed by adding a small amount of Ni, Fe, Cu, Co, Mo, Cr and other elements into tungsten (generally with the conte... |

|

|

high-temperature strength creep resistance Molybdenum Piercing Mandrel |

With excellent high-temperature strength and creep resistance, TZM alloy can be used for manufacturing mandril ejectors of seamless steel pipe pene... |

|

|

easy to machine Tungsten-lanthanum hot sale Chinese supplier |

Tungsten-lanthanum alloy is formed by adding lanthanum oxide (La2O3) with the weight percent of 1% to 2% into tungsten to improve its creep resista... |

Все товары поставщика

Похожие товары