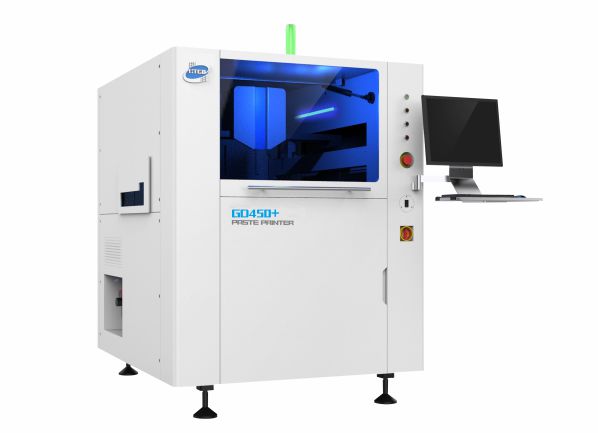

Online AOI Machine S810

Online AOI Machine S810

- Inspection Component: 01005 chip

- PCB size::50×70mm-510×460mm

- Dimension:1000mm×960mm×1600mm

- Weight: 710kg

- Product description: Online AOI Machine S810,Inspection Component: 01005 chip,PCB size::50×70mm-510×460mm,Dimension:1000mm×960mm×1600mm,Weight: 710kg

- INQUIRY

Online AOI Machine S810

Products description

Flexible / versatile AOIDifferent models are suitable for the production of multiple quality control positions in the line, including 2D solder paste quality inspection after solder paste printing, component measurement before reflow soldering, PCBA process quality inspection after reflow soldering, and hand-insertion wave soldering inspection

New light source designThe multi-angle multi-angle light source design scheme is used to sample the detailed features of the detected object by different angles of illumination, and the assembly and welding information of the component are accurately obtained, and the defect is effectively eliminated.

Comprehensive application of multiple software detection algorithmsIt integrates more than 30 kinds of software detection algorithms, integrates a variety of vector information analysis and calculation, and adopts a tree form program editing architecture. It can define various inspection items according to the detection requirements, and can accurately cope with the poor appearance analysis of various electronic assembly and welding processes.

Visual acquisition systemThe vision system is the eye of AOI, and the S810 uses a 5 megapixel industrial camera imported from Germany, which has a very high color reproduction effect.With high-resolution, high-definition telecentric lens, the product has high recognition accuracy and provides high-definition image output for AOI equipment.

Motion Control SystemMulti-axis coordinated control of multiple servo motors using high-performance DSP and large-scale programmable devices with 4-axis motion control card with independent intellectual property rights

central control systemCentral server mode, which can collect test information of all machines through the central control server, which is convenient for comprehensive management of production. Only one operator is needed for multiple devices.

Main components of the equipmentServo control system: All imported servos and motors imported from Japan to ensure high-precision transmission control.Screw and slide rail: Adopt high-precision ball screw and slide rail imported from Japan.PLC: Imported from Germany.Pneumatic control system: imported pneumatic control accessories imported from Japan and Taiwan.

The whole board matches the multi-piece detection function at any position.Imported industrial camera with high frame rate, combined with industrial telecentric lens, adopts high-speed dynamic image acquisition, can complete hundreds of image information collection tasks per second, combined with the whole board matching algorithm in software, can be used anywhere on the board. Accurate detection of multiple pieces, foreign objects, scratches, etc.

Comprehensive and detailed SPC softwareThe SPC database can perform detailed analysis of the daily test data for pie analysis, alignment analysis, column analysis, trend analysis, etc.SPC can feedback the information of the production line in real time, so that engineers and technicians can respond as soon as possible, find the root cause of the problem and solve it as soon as possible.

Feature:

- 99%, Repeat accuracy 3 pcs, False Negative 10PPM, False Positive 5000PPM

Inspection System & Optical System

|

Inspection Object |

Skew / Tombstone / Wrong part / Missing / Overturning / Damaged /Cold joint / insufficient solder / Excess solder |

|

Inspection Component |

0201 chip , IC pitch 0.3mm, wave soldering point |

|

Inspection Method |

Color image comparison, OCR, IC Short Analysis, Graphics Similarities Analysis, Color Analysis, Gray Analysis |

|

Camera |

Color CCD (2M) , Resolution 15um, FOV 24*18mm, Speed :2000 mm2/s |

|

Light Source |

RGB cascade multi-angle LED combination lighting, high brightness, 2M pixels tele-centric lens, DOV:8mm |

Software & Computer

|

Inspection capability |

120 points/sec ; programming time : 1-1.5 hr/1000 components, NG inspection rate >99%False reject rate : 005 - 3.0% (repeatability <3pcs) , False accept rate <0.01% |

|

Mark Recognition |

2 points, support multi-board multi-mark points, support bad mark ; Process speed 0.5sec/pcs |

|

Computer |

Dual core 2.7G, DDR II 2.0G, 500G harddisk, 22"wide screen LCD |

Mechanical System

|

PCB Thickness |

|

|

PCB Height |

Top: 30mm, Bottom 35mm (can be customized) |

|

Driving Method |

AC Servo Motor + ball screw rod + linear guide rail |

|

Motion Speed |

Max 700mm/s |

|

PCB Size |

510*460mm, Auto-width adjustment |

|

Conveyor Height |

900± 20mm |

|

Power |

220V/50Hz, 650W,UPS 1000 VAuninterruptible power supply |

|

Compressed Air |

Max 0.3MPa |

|

Dimension |

1000mm×960mm×1600mm(alarm lamp height not included) ;alarm lampheight:550mm |

|

Weight |

710kg |

Keywords:

AOI Machine,Panasonic AOI Machine,SMT AOI Machine,PCB AOI Machine

Flason Electronic Co, Ltd provide a fullSMT Assembly Linesolutions, includingSMT reflow oven,Wave Soldering Machine,Pick and Place Machine,solder paste printer,PCB loader,PCB unloader,SMT AOI Machine,SMT SPI Machine,SMT X-Ray machine,SMT assembly lineequipment,smt spare partsetc, any kind SMT machines you may need, please contact us by: Email: