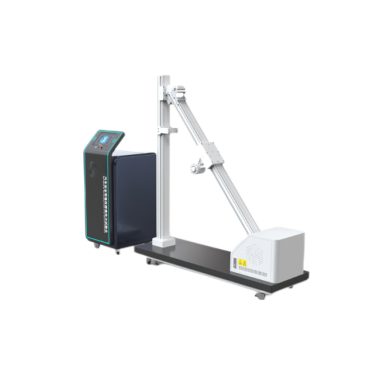

360 rotary tank cleaning equipment, orbital tank washer

High impact 3D rotary tank washer

Working Principle:

Impeller is driven by cleaning fluid and drives internal reduction mechanism. Gear mechanism operates according to set track to realize the revolution and the rotation, thereby achieving 360° thorough cleaning.

Programmed rotation machines:The cleaning fluid drives via the turbine an internal gear reducer that keeps the sprayer turning in two planes.In the course of spraying cycle, the jets sweep the entire inside surface of the tank according to the preprogrammed, model-specific pattern.This takes a certain amount of time, but these models generate the highest jet pressures (= force of impact) and are therefore ideal for very large tanks and the toughest of cleaning tasks.

The standard machine configuration uses two or four nozzles to blast the tank walls and rinse all surfaces. In operation, the unit has to run for the cycle time between on type 8 and 12 min depending on type and pressure. This ensures full cleaning. For extremely difficult applications the cleaning time might have to be extend.

●Optimized structural design results in a water jet that produces greater impact

●Excellent sealing design, less than 3% leakage, thus saves cleaning fluid

●Independent gearbox design protects gear from damage and can work inpoor water quality

●Adopt high hardness and wear resistant materials, long service life

TApplication:

STD DG5 rotary tank washer is suitable for 3D cleaning of small to medium sized tanks,vessel or machines. It is commonly used in beer industry, petroleum, beverage,fuel ethanol, chemical, industrial fermentation,marine and where a high cleaning performance is required.

● Storage tank

● Fermentation tank

● IBC totes

● Fish vessel

● Reactors

●Process vessels

●Underground storage tanks (USTs)

●Rail cars

●Dryers, silos, towers (2d)

Отправить запрос, связаться с поставщиком

Другие товары поставщика

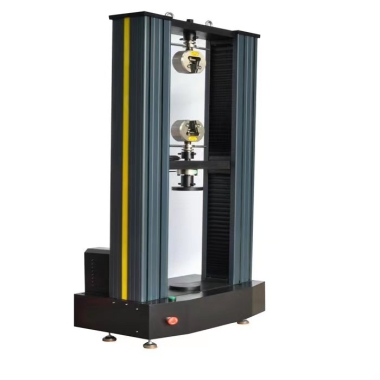

| Geosynthetics thickness tester-QINSUN | Scope of application: Used to determine the thickness of various geosynthetic materials under specified pressure and time. The sample is placed on... | |

| Retractable CIP rotary spray nozzle | STD-150 retractable CIP rotary spray nozzle Dynamic Retractor CIP systems clean even the remotest corners. Where to attach the spray head? This qu... | |

| Automotive Comfort Air Conditioning Dummy Test System | Applicable standards: ISO related standards, such asISO 14505-2. which provide test methods and evaluation indicators for thermal comfort. Berkel... | |

| Industrial water purifier | Applicable Standards Industrial water purifier systems adhere to global purity and safety benchmarks, including: ASTM D1193(Specifications fo... | |

| Fabric Anti-Electromagnetic Radiation Performance Tester | Standards GB/T23326. GB/T25471. ASTM D4935. SJ2054 Application It is used for testing the electromagnetic shielding effectiveness of electromagn... |

Похожие товары

| Seat Bumping and Creep Test Bench | Продавец: Standard International Group (HK) Limited | This test bench is used for simulating the car seat bumping and creep situation when a car is run... | |

| Automobile seat belt fixed point test bench | Продавец: Standard International Group (HK) Limited | Applicable standards: National mandatory standards: GB 15083-2006"Automobile seats, seat fixtur... | |

| Impact strength tester for car seat headrest | Продавец: Standard International Group (HK) Limited | Applicable standards: GB 15083-2006 "Automobile seats, seat fixtures and headrest strength requi... | |

| Impact strength tester for car seat launching headrest | Продавец: Standard International Group (HK) Limited | Main parameters: Impact speed:The impact speed of the tester is usually between 25 and 30km/h, w... | |

| Automobile Headrest Strength Tester | Продавец: Standard International Group (HK) Limited | Applicable standards: GB 11550-2009"Automobile seat headrest strength requirements and test me... |