Sterile Agitated Nutsche Filter Dryer(ANFD)

The Agitated Nutsche Filter Dryer(ANFD) has formed two major series of about 40 specifications since 2001. We are the drafting unit of National Standards of Pharmaceutical Agitated Nutsche Filter Dryer.

Application: ◆Intermediates for pharmaceutical and sterile API ◆Biological pharmacy ◆Fine chemical industry ◆Printing and dyeing industry

Functions: ◆Feeding ◆Filtering: Solid-liquid separating is carried out under vacuum or pressurization condition. ◆Filter cake smoothing: The agitator rotates anticlockwise to smooth the crevices of the filter cake surface so as to avoid short circuit of cleaning solvent whenmeeting the crack. ◆Slurry mixing and cleaning: The cleaning fluid can be sprayed on the container evenly by the rotating spray ball, which can carry out inner cleaning and filter cake cleaning. By raising and lowering the agitator, the filter cake and the cleaning fluid can be mixed so as to clean the filter cake adequately. ◆Drying: In the case of vacuum, the agitator rotates clockwise toheat and scrape the cake loosely. The heating system of the equipment heats the wet liter cake to vaporize solvent. ◆Sampling on Line: Take sample by sampling valve during drying process. ◆Side discharging: After drying the agitator shall rotate clockwise to scrape and propel materials out of the side discharging valve nozzle automatically. ◆CIP and SIP

Features:

◆The design and assembly of the equipment is carried out strictly following the national GMP and the US FDA requirements, and fully conforming to pharmaceutical production process requirements. The system is safe, stable and reliable. ◆The equipment materials are strictly controlled. The parts that directly contact with materials are made of SS316L, PTFE or EPDM sealing materials. The filtrate plate is made of SS316L sintered mesh , which avoids producing fiber. ◆The interior surface of the equipment that directly contact materials are flat and smooth without dead corner which is convenience to clean and sterilize.

◆The equipment does not contaminate the external environment, and dust prevention, leakage prevention, heat insulation and noise prevention technologies are properly adopted. Under the fully closed working status, the motor, gear box and lifting device are protected by stainless steel covers and the jacket reflow channel is plus with heat preservation carpet used for heat insulation so as to well reduce heat loss and influence from the outside. ◆ Safe and reliable explosion-proof electrical appliances are adopted. The pulleys that can eliminate static electricity and other safe interlocks and safety devices are allocated. ◆All the pipes of materials, solvents and nitrogen gas are designed to have no dead corner or blind pipe. The equipment surface is subjected to mechanical automatic fine polishing or electrolytic polishing with the interior surface Ra≤0.4 and the exterior surface Ra≤0.8. ◆The blending shaft and lateral discharging valve stem are installed with bellows. ◆The removable rotary cleaning spray ball is used for CIP. ◆Double-face dry mechanical seal, nitrogen protection and cooling. ◆Dust capture device with CIP.

Basic parameters:

| Model | Filtering surface area(㎡) | Internal diameter (mm) | Nominal volume(m3) | Filter cake height(mm) | Blade lifting height(mm) | Motor power(kw) | Net weight(kg) | Total height(mm) |

| DN325 | 0.08 | 325 | 0.04 | 100 | 120 | 0.37 | 600 | 2050 |

| DN400 | 0.125 | 400 | 0.07 | 120 | 150 | 0.55 | 860 | 2550 |

| DN500 | 0.19 | 500 | 0.14 | 100 | 150 | 2.2 | 1450 | 2700 |

| DN600 | 0.28 | 600 | 0.22 | 150 | 200 | 2.2 | 1700 | 3250 |

| DN800 | 0.5 | 800 | 0.46 | 180 | 220 | 3 | 2250 | 3600 |

| DN1000 | 0.8 | 1000 | 0.95 | 200 | 250 | 5.5 | 3500 | 4100 |

| DN1200 | 1 | 1200 | 1.2 | 250 | 300 | 7.5 | 4900 | 4000 |

| DN1400 | 1.5 | 1400 | 1.9 | 300 | 350 | 11 | 6500 | 4500 |

| DN1600 | 2 | 1600 | 2.59 | 300 | 350 | 15 | 7400 | 4650 |

| DN1800 | 2.5 | 1800 | 3.2 | 350 | 400 | 15 | 10000 | 4700 |

| DN2000 | 3 | 2000 | 4.5 | 400 | 450 | 18.5 | 11700 | 5100 |

| DN2300 | 4 | 2300 | 6.4 | 400 | 450 | 22 | 12800 | 5200 |

| DN2600 | 5.3 | 2600 | 9 | 400 | 450 | 22 | 16250 | 5200 |

Send product request

Other supplier products

| Aluminum Cap Cleaning Machine | Developed since 1996, the aluminum cap cleaning, sterilizing and drying equipment has been developed into the sixth generation, forming two major s... | |

| Rubber Stopper Cleaning Machine | Developed since 1996, the rubber stopper cleaning, sterilizing and drying equipment has been developed into the sixth generation, forming two major... | |

| Sterile Agitated Nutsche Filter Dryer(ANFD) | The Agitated Nutsche Filter Dryer(ANFD) has formed two major series of about 40 specifications since 2001. We are the drafting unit of National Sta... |

Same products

| Investment Cast Valve Body Component | Seller: Qingtian Baoli Casting Co., Ltd. | The Investment Cast Valve Body Componentis developed for industrial valve systems requiring accur... | |

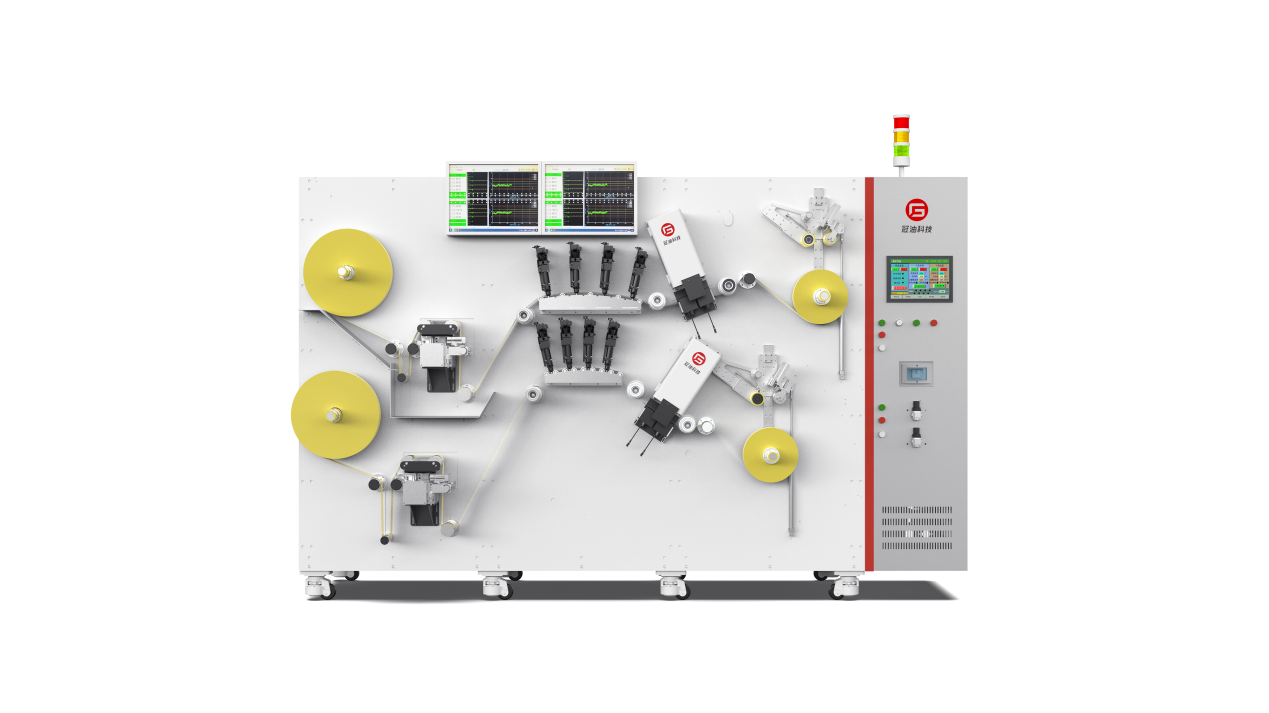

| Double Workstations 16-head cigarette tipping paper Laser Perforating Machine | Seller: Wuhan Guan You Technology Co., Ltd. | During the smoking process, the gas inhaled into the smoker's mouth is not solely composed of the... | |

| CNC-YF-8208/8212 2-Axis Small Compression Spring Coiling Machine | Seller: Zhejiang Yinfeng Automation Technology Co., Ltd. | The 2-axis Spring Coiling Machine offers a reliable and efficient solution for spring manufacturi... | |

| Off Grid Solar System Supplier | Seller: Henan JM Solar Energy Solution Co.,Ltd | Off Grid Solar System Supplier Off Grid Solar System An , also known as a stand-alone sol... | |

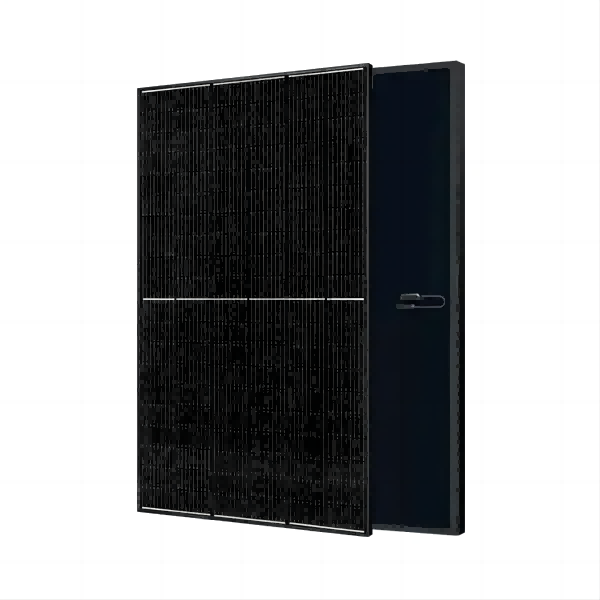

| perc solar panels | Seller: Henan JM Solar Energy Solution Co.,Ltd | perc solar panels (Passivated Emitter and Rear Cell) solar panels represent an advancement i... |