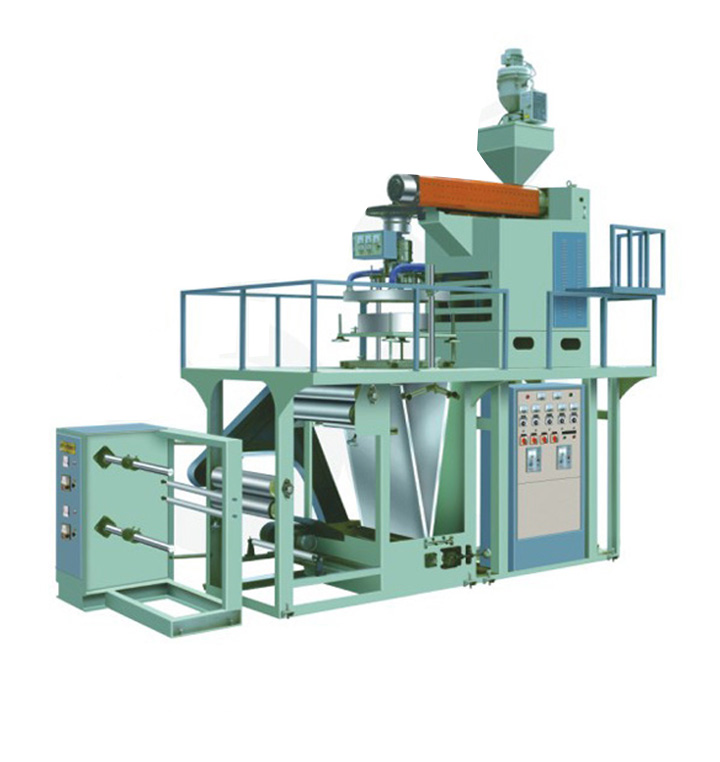

Bottom Film Blowing Machine Set

The Closest Service:

1.Free installation and ajustment.(for consumers purchase more than $100000 only)

2.One year free after-sales service and mechanical parts lifetime warranty.

3.No charge for changing parts in one year by TNT Express.

Purpose

Making use of bottom blowing technology, this machine set is used to blow PPL, LDPE and HDPE plastic film to produce various civil and industrial packaging bags of food, clothing, textile and article of daily use, etc.

Feature

It can rotate in 360 degrees to enhance the strength and uniformity of plastic films

Both the screw and the charging barrel are made of 38 CRMOALA alloy steel through nitrogen treatment and precision machining with the optimal hardness, corrosion resistance and outstanding durability.

The die head is plated with hard chrome with a structure of screw spindle type; the extruded molten materials are well distributed and the blown film is of smooth finish; the air cooling device is of maze structure with well-proportioned air volume. It adopts circulating water cooling method to reach the best transparency of the film.

The winding unit adopts pressure friction or center winding and the torque motor to adjust to ensure the flat winding and convenient changing

Main Technical Parameters

Model CHSJ--40F CHSJ--45F CHSJ--50F CHSJ--60F

Diameter of screw 40 mm 45 mm 50 mm 60 mm

L/D ratio of screw L/D 30:1

Specification of die head 80 mm 90 mm 160 mm 180 mm

Film thickness 0.015-0.06 mm

Folding width of film 30-250 mm 35-400 mm 50-500 mm 50-600 mm

Total power 11 kw 15 kw 18 kw 21 kw

Capacity 10-25 kg/h 10-35 kg/h 10-48 kg/h 10-70 kg/h

Machine weight ≈1.9 T ≈2.0 T ≈2.1 T ≈2.2 T

Overall dimension 5*2*3.3 m 5.2*2.1*3.4 m 5.3*2.2*3.5 m 5.4*2.3*3.6 m

Other supplier products

All supplier products

Same products