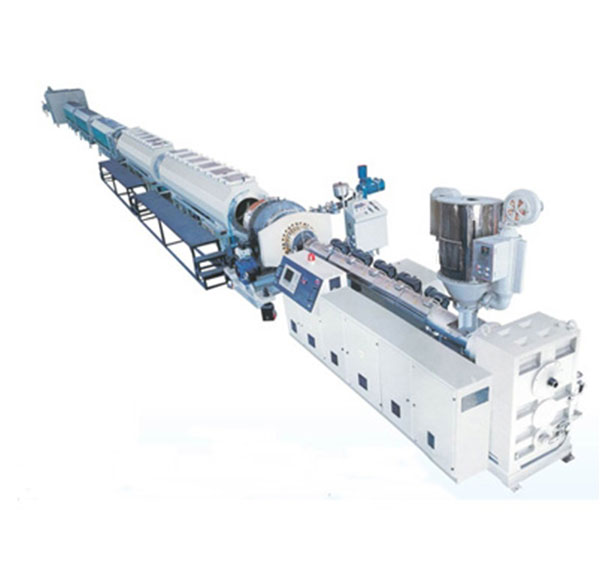

Plastic Pipe Production Line

This machine developed by Kailite company plastic pipe production line manufacturersis featured of unique structure, a high degree of automatic, easy operation and stable reliable continuous manufacture performance can meet all kinds of plastic pipe production needs.

Plastic Pipe Production LineList

High Pressure Helical Hose Sheath Production Line

PVC Woven Fiber Reinforced Pipe Production Line

GF-63 Twin Pipe Extrusion Production Line

PVC Rigid Pipes Production Line

Corrugated Optical Cable Pipe Production Line

PVC Double Pipe Production Line

PVC Double-wall Corrugated Pipe Production Line

PVC Pipe Production Line

How to Extrude PVC Pipe?

- In the vacuum cooling machine, it is better shaped by water and vacuum cooling and blowing the tube

- Pull down the pipe at the same extrusion speed to control the production speed and pipe thickness

- Use a cutter to cut the tube into a customized length (fix the length with a limit switch or a rotary encoder)

- Automatic loading and unloading of pipes by stacker (controlled by limit switch)

PVC Pipe Extrusion Process

The plastic raw materials are loaded into the hopper and then fed into the extruder machine.

The molten plastic material is moved through the extruder by rotating bolts. It is important to note that some extruders can have one or two rotating bolts.

The molten raw material flows down from the feed hopper through the feed throat and flows to the large spinning screw running in the horizontal barrel of the micro single screw extruder.

In a horizontal bucket, the molten material is filtered to ensure a uniform consistency.

The performance of the plastic material will vary according to the material it is made of. However, relative to the type of raw material passed, the raw material is processed by heating it at a specific temperature.

After processing, the molten plastic is pushed into a small opening called a mold. This allows the material to be sized or shaped to the desired final size.

The die cutting for specific plastic profiles is designed to help smooth and even flow from the cylindrical profile of the extruder to the final profile shape.

The consistency of plastic flow is essential to obtain a high-quality and reliable final product.

When the plastic is extruded from the mold, it is transported to a conveyor belt for cooling. The finished product can be cooled by air or water.

Features & Advantages of Plastic Pipe Production Line

Main extruder has advantages of wide adjustment range, high precision, convenient operation and so on.

The haul-off is specially designed by our company with a fast and smooth movement for the big profile.

The vacuum calibration tank adopts a special cooling system to ensure the sizing effect.

The moving speed of the cutter and haul-off are synchronous and the speed is controlled by PLC computer.

According to different molds, calibration tank of 4m, 6m, 8m and 11m can be chosen.

Qingdao Kailite plastic machinery Co., LTD. is aprofessional plastic pipe production line manufacturers, we provide tube extrusion line, tube extrusion and pipe making, pipe line plastics, plastic pipe extrusion line, pipe extrusion line, plastic pipe extrusion machine, wood plastic extrusion lineand etc. Want to know more? Please contact us.

Send product request

Other supplier products

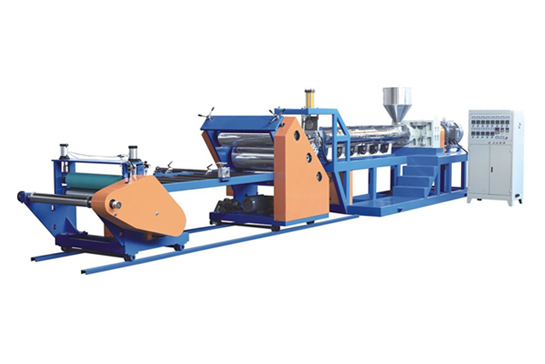

| Kailite Plastic Extrusion Machinery | Plastic extrusion is defined as a manufacturing process (high-volume), in which the raw plastic / raw plastic material is melted and then formed in... | |

| PE Foamed Sheet/Film Production Line | ( WIDTH ) 700-2000MM ( THICKNESS ) 0.5-15MM Polyethylene foamed sheet ( film ), also named as pearl cotton. Performance & Advantages of ... | |

| PP-R/PP/PE Plastic Tube Production Line | That production line design special, adoption BM separate type efficiently the pole of automating the degree is high, operation convenience, contin... | |

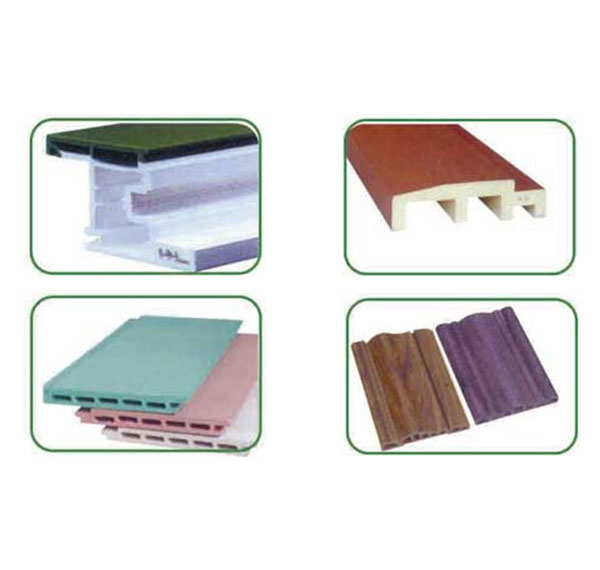

| Plastic Extruding Profile Production Equipment | This line is the manufacture facilities of PVC plastic profile materials, including window and door series profile, plate, sheet, tiny bubble profi... | |

| Plastic Pipe Production Line | This machine developed by Kailite company plastic pipe production line manufacturersis featured of unique structure, a high degree of automatic, ea... |

Same products

| Iron Single Adjustable Cafe Rod Set | Seller: Deqing Bochuang Hardware Co., Ltd | The Iron Single Adjustable Cafe Rod Setis a durable and stylish window treatment solution. Featur... | |

| Competitive Price OEM Waterproof Nylon Injection Molding Parts | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| Wholesale Plastic Injection Insert Molding Custom Plastic Parts | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Pla... | |

| Professional Factory Supply Custom Plastic Injection Molding Service | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... | |

| China Factory OEM High Quality Plastic Molded Parts Plastic Injection Molding Price | Seller: Hebei Erye Rubber & Plastic Products Co.,Ltd | Product Specification Description Products Name: Custom plastic and rubber parts Materials: Plast... |