MOLD TEMPERATURE MACHINE CONTROLLER BY SOXI: ALWAYS THE RIGHT CHOICE

Mold temperature machine, MTC, mold heater, In a broad sense, called mold temperature controller, oil/water mold heaters. Mold temp controller contains heating and freezing temperature control. it is used to heat up the mould and maintain temperature.

Soxi is one of the earliest mould temperature controller manufacturers. When other mold temperature controller suppliers were producing traditional controllers, soxi developed first mould temperature controller China for high-gloss plastic in car parts and home appliance.

With accurate temperature control, mold temperature controller has many models for various applications such as injection molding, die-casting molding, extrusion molding, printing, reaction still/reactor, roller industries. By speeding up the production rate, reducing energy consumption, and saving energy. Mold temp controller is important equipment to ensure industrial processes are always operating at an optimal level.

Types Of Mold Temperature Controller

Soxi provides a wide range of plastic auxiliary machines which includes temperature controller for RHCM Moling, oil-type mold temperature controller, water mold temperature machine, a steam conversion machine, hot and cold integrated mold temp. controller.

Mold Temperature Controller China Development History of RHCM Molding

It Converges steam-forming Technology from Japan, South Korea, and Europe. The expensive and complicated boiler system was disposed of. Adopts standalone design and has a smaller size, it can be as portable as a commonly use mold temperature controller. The investment is small compared to benefits; clients are able to reclaim costs in a very short period. SOXI provides a complete traceless molding solution including traceless (highlight) mold design, mold testing, and production.

-In April 2007: the first generation of high gloss mold temperature controller which does not require a boiler was invented by SOXI technical team. It has a huge Size of 3.4M x 1.2M x 2.2M.

-In February 2008: We made the second generation of the high light control device which does not require boilers, and obtained national patents( patent number: .0)

and the European Union CE certification

-August 2009: The third generation was released and exported to Mexico and Hungary. Up to 2011 had gained a market share of more than 50%.

-During the period from 2012 to 2018: we bring our fourth generation RHCM molding temp controller; RHCM plastic mold temperature controller looks more aesthetical and saves energy. it is more Eco-friendly than the previous generation.

-At present: we bring to the market the fifth generation of high-gloss mold temperature controllers. With an updated design and bold innovation. All our works have one ultimate goal that is to build better products and meet clients' requirements.

Why Should Choose Mold Temperature Controller System Developed By Soxi?

Soxi is one of the earliest mould temperature controller manufacturers. When other mold temperature controller suppliers were producing traditional controllers, soxi developed first mould temperature controller China for high-gloss plastic in car parts and home appliance.

E-MOLD system: With the use of mold temperature machine directly installed in the mold heating system, the mold cost is higher, and the expensive mold design royalties to pay.

RHCM system: Is the system that uses high-temperature and high-pressure steam as the heat transfer medium. The RHCM system is the earliest, and the mold of this system is relatively mature. The steam can not be recycled in the production process, and the boiler equipment needs to be installed, resulting in high running costs. Research and commercialization Manufacturers using RHCM systems are mainly concentrated in Japan (eg Ono, Mitsubishi, Fuji Seiko, etc.).

SOXIHOT system (patent number: .0): SOXIHOT system is the first SOXI company after years of research and development of a temperature control system and obtained the relevant patents, the system uses high-pressure hot water (the use of pressure to change the boiling point of water) as a heat transfer medium, in China, the system is the first launch and It is used by a number of enterprises such as Flextronics (one of the world's top 500 leading enterprises) and its molds are compatible with the mold design of RHCM system. The secondary high-pressure hot water is recycled so that the energy can be greatly saved to reduce the operating cost. The system's control method is simple and can be based on the actual situation of choice, the control mode has timer control, signal control, temperature control in three ways, the system is stable and easy to operate without professionals, ordinary employees can operate, internal design has more than 10 safety Protection device to ensure zero accidents.

Why Should Choose Mold Temperature Controller System Developed By Soxi?

What Are The Main Features Of Soxi RHCM Temperature Controller And Application?

Multi-Purpose High-Light Mold Temperature Controller Uses

For the LCD TV, LCD computer, LCD monitors, lights and optical instruments, and other industries, in addition to flat-panel TV panels, this technology can also be widely used in computer LCD monitors, air conditioners, automotive interiors, and other appliances, Automotive, communications, medical and other industries.

Multi-Function High-Light Mold Temperature Controller Technology Advantages

The mold temperature machine combines the steam forming technology of Japan, South Korea, and Europe to remove the expensive and complicated boiler system, and combines the unique characteristics of domestic enterprises with the single-machine design. The equipment is small in size and strong in maneuverability and can be moved like a common mold temperature machine, Small investment returns fast, the company can provide a set of enterprises for traceless (highlight) molding programs, including traceless (highlight) mold design, test mode, production.

As a professional plastic machine factory, we provide plastic processing machine, plastic washer and dryer, injection moulding machineand etc. For mold temperature controller priceand more information, please feel free to contact us!

Send product request

Other supplier products

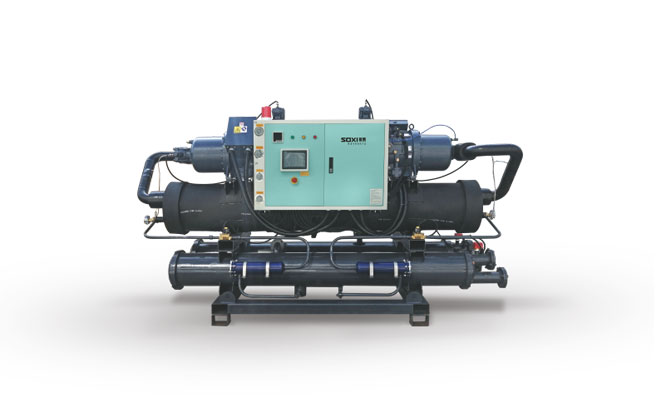

| AIR COOLED SCREW CHILLER | The air-cooled chiller adopts a finned condenser, which has fast heat conduction and good heat dissipation effect without the need to provide cooli... | |

| Water Cooled Screw Chiller | The water-cooled screw refrigeration unit adopts a shell and tube condenser, which has fast heat conduction and good heat dissipation effect. It ca... | |

| SOXI PLASTIC MOLDING MACHINE MANUFACTURERS | Are you in the market for a new plastic moulding machine but just not sure how or where to start? Soxi can be your competitive plastic molding mach... | |

| MOLD TEMPERATURE CONTROLLER BY SOXI: ALWAYS THE RIGHT CHOICE | Mold temp controller, MTC, mold heater, In a broad sense, called temperature control equipment, oil/water mold heaters. Mold temp controller contai... | |

| HOT AIR DRYER | The hot air dryer for plastic can be directly installed on the injection molding machine. Hot air enters evenly from bottom to top to ensure a good... |

Same products

| Caco3 Masterbatch HD-Ca02 | Seller: Tianjin Hongda Color masterbatch Co., Ltd | Caco3 Masterbatch HD-Ca02 Caco3 Content 82% Mesh 1250 ... | |

| White Masterbatch HD-2601 | Seller: Tianjin Hongda Color masterbatch Co., Ltd | Our factory specializes in manufacturing plastic color master batchesfor many serveces on advance... | |

| Black masterbatch HD-1608 | Seller: Tianjin Hongda Color masterbatch Co., Ltd | We have expert knowledge in production-processes for various applications in the plastics industr... | |

| ELECTRET MASTERBATCH | Seller: Zhejiang Honye New Materials Co., Ltd | ELECTRET MASTERBATCH An Electret Masterbatchrefers to a parent granule that retains charge in a ... | |

| CUSTOM COLOR MASTERBATCH | Seller: Zhejiang Honye New Materials Co., Ltd | CUSTOM COLOR MASTERBATCH Honye offers high-quality custom compounding color masterbatchwith fact... |