Silicone Human Body RTV2 Medical Grade Platinum Liquid Silicone Rubber Mold for Lifecasting

Product Description

Specification

Addition Cured Silicone Rubber for Mold Making, which is also named addition cure silicone rubber and platinum cure silicone rubber, is generally a two-component liquid silicone rubber vulcanized under room temperature(RTV-2).

Applications

Addition Cured Silicone Rubber has extensive use,such as mold making of foods (candy,cake, cookie,chocolate, ice cube, fondant etc), jewelries, tires, rapid prototyping,life casting,realistic mask,epoxy resin products,candle,vacuum foaming,making of prosthetic breast,artificial skin,human body,adult toys,baby feeding nipples, case and so on.

Techinical Parameters

How to use

1.Substrate Preparation

The surface of the original should be clean and free of loose material. If necessary, and in particular with porous substrates, use a suitable release agent such as petroleum jelly or soap solution.

2. Mixing

Thoroughly stir Part A (silicone base) before use as filler separation may occur upon prolonged storage.

Weigh 100 grams PartA (silicone base) and 3 grams Part B (curing agent) in a clean container. Mix together until the curing agent is completely dispersed in the base. Hand or mechanical mixing can be used, but do not mix for an extended period of time or allow the temperature to exceed 35°C (95°F). Mix suitably small quantities to ensure thorough mixing of the par A (silicone base) and part B (curing agent).

It is strongly recommended that entrapped air be removed in a vacuum chamber, allowing the mix to completely expand and then collapse. After a further 1-2 minutes under vacuum, the mix should be inspected and can be used if free of air bubbles. A volume increase of 3-5 times will occur on vacuum de-airing the mixture, so a suitably large container should be chosen.

Caution: prolonged vacuum will remove volatile components from the mix and may result in poor thick section cure and non-typical properties.

Note: If no vacuum de-airing equipment is available, air entrapment can be minimized by mixing a small quantity of par A (silicone base) and part B (curing agent), then using a brush, painting the original with a 1-2mm layer. Leave at room temperature until the surface is bubble free and the layer has begun to cure. Mix a further quantity of base and curing agent and proceed as follows to produce a final mold.

3. Pouring the Mixture and Curing

Pour the mixed Par A (silicone base) and Part B (curing agent) as soon as possible onto the original, avoiding air entrapment. The catalyzed material will cure to a flexible rubber within 24 hours at room temperature (22°C-24°C/ 71.6°F - 75.2°F) and the mold can then be separated from the original. If the working temperature is significantly lower, the cure time will be longer. If the room temperature or humidity is very high, the working time of the catalyzed mixture will be reduced. The final mechanical properties of the mold will be reached within 7 days.

Addition Cured Silicone Rubber for Mold Making, which is also named addition cure silicone rubber and platinum cure silicone rubber, is generally a two-component liquid silicone rubber vulcanized under room temperature(RTV-2).

Applications

Addition Cured Silicone Rubber has extensive use,such as mold making of foods (candy,cake, cookie,chocolate, ice cube, fondant etc), jewelries, tires, rapid prototyping,life casting,realistic mask,epoxy resin products,candle,vacuum foaming,making of prosthetic breast,artificial skin,human body,adult toys,baby feeding nipples, case and so on.

Techinical Parameters

| ModelCode | GTSIL-P10 | GTSIL-P15 | GTSIL-P20 | GTSIL-P25 | GTSIL-P30 | GTSIL-P35 | GTSIL-P40 |

| Hardness-ShoreA | 8-10 | 14-16 | 19-21 | 24-26 | 28-30 | 34-36 | 38-42 |

| Viscosity-Cps | 3000-5000 | 4000-6000 | 4000-7000 | 5000-8000 | 6000-9000 | 6000-10000 | 4000-6000 |

| MixingRatio-% | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 | 1:1 |

| TearStrength-KN/m2 | 14-17 | 16-18 | 18-22 | 22-26 | 20-23 | 16-19 | 12-16 |

| TensileStrength-Mpa | 3.5-5.5 | 4-6 | 4-6 | 4-6 | 4-6 | 4-6 | 3.5-5.5 |

| Shrinkage-% | 0.10% | 0.10% | 0.10% | 0.10% | 0.10% | 0.10% | 0.10% |

| Elongation-% | 500-600% | 500-600% | 500-600% | 400-500% | 400-500% | 350-500% | 300-450% |

How to use

1.Substrate Preparation

The surface of the original should be clean and free of loose material. If necessary, and in particular with porous substrates, use a suitable release agent such as petroleum jelly or soap solution.

2. Mixing

Thoroughly stir Part A (silicone base) before use as filler separation may occur upon prolonged storage.

Weigh 100 grams PartA (silicone base) and 3 grams Part B (curing agent) in a clean container. Mix together until the curing agent is completely dispersed in the base. Hand or mechanical mixing can be used, but do not mix for an extended period of time or allow the temperature to exceed 35°C (95°F). Mix suitably small quantities to ensure thorough mixing of the par A (silicone base) and part B (curing agent).

It is strongly recommended that entrapped air be removed in a vacuum chamber, allowing the mix to completely expand and then collapse. After a further 1-2 minutes under vacuum, the mix should be inspected and can be used if free of air bubbles. A volume increase of 3-5 times will occur on vacuum de-airing the mixture, so a suitably large container should be chosen.

Caution: prolonged vacuum will remove volatile components from the mix and may result in poor thick section cure and non-typical properties.

Note: If no vacuum de-airing equipment is available, air entrapment can be minimized by mixing a small quantity of par A (silicone base) and part B (curing agent), then using a brush, painting the original with a 1-2mm layer. Leave at room temperature until the surface is bubble free and the layer has begun to cure. Mix a further quantity of base and curing agent and proceed as follows to produce a final mold.

3. Pouring the Mixture and Curing

Pour the mixed Par A (silicone base) and Part B (curing agent) as soon as possible onto the original, avoiding air entrapment. The catalyzed material will cure to a flexible rubber within 24 hours at room temperature (22°C-24°C/ 71.6°F - 75.2°F) and the mold can then be separated from the original. If the working temperature is significantly lower, the cure time will be longer. If the room temperature or humidity is very high, the working time of the catalyzed mixture will be reduced. The final mechanical properties of the mold will be reached within 7 days.

Send product request

Other supplier products

| Silicone Compound FDA Platinum Liquid Silicone Rubber Mold for Epoxy Resin Moldmaking | Product Description SpecificationAddition Cured Silicone Rubber for Mold Making, which is also named addition cure silicone rubber and plati... | |

| Hot Sale Liquid Silicone Tin Cured Moldmaking Silicone Rubber for Gypsum Plaster Decoration | Basic Info. Model NO. GTSIL-T15~T25 Shelf Life 10 Months or 12 Months Certificates FDA;MSDS;Reach;RoHS Type Tin C... | |

| Silicone Human Body RTV2 Medical Grade Platinum Liquid Silicone Rubber Mold for Lifecasting | Product Description SpecificationAddition Cured Silicone Rubber for Mold Making, which is also named addition cure silicone rubber and plati... |

Same products

| life casting food grade silicone rubber soft sex doll two parts liquid silicone | Seller: SHENZHEN INIBABA TECHNOLOGY CO., LTD. | life casting food grade silicone rubber soft sex doll two parts liquid silicone platinum cure si... | |

| life casting food grade silicone rubber soft sex doll two parts liquid silicone | Seller: SHENZHEN INIBABA TECHNOLOGY CO., LTD. | life casting food grade silicone rubber soft sex doll two parts liquid silicone Description Tw... | |

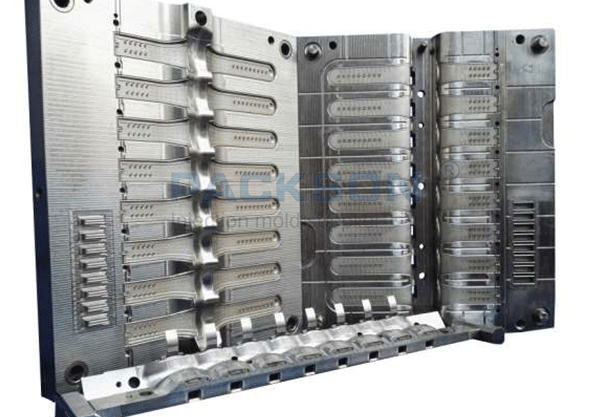

| Silicone Rubber Mold | Seller: Packson Mold Co.,Ltd | Silicone rubber is a kind of elastic material, which is widely used in industry and family. It ha... | |

| Embossed Silicone Rubber Wristbands/Bracelets Bulk | Seller: Yppromotion | In addition to those ordinary wristband types, YP Promotion also has a novel technology that can ... | |

| SILICONE BRACELET | Seller: Yppromotion | The silicone bracelet is made of solid silicone rubber pressed by an oil press. Wholesale persona... |