Fiber Optic Corner Pressure Polishing Machine

Product DescriptionCE Fiber Optical Polishing MachineThe Fiber Optical Polishing Machine On The Base Of International Universal Standards And Long-Term Hands-On Experience, It Exceeds Requirements For Gr-326 End Face Geometry, And This Fiber Optical Polishing Machine Adapt To Four Corners Compression And New I. P. C. Holder Technology Yields The Best Results In The Industry. No Variability In Result When Polishing 1 Or 24 Connectors, Jig Will Be Installed Stable, And Compact Size. This Fiber Optical Polishing Machine Can Process Excellent Connector End Force Polishing Quality. Our This Type Of Fiber Optical Polishing Machine Designed For Volume Production, High Productivity. For More, The Fiber Optical Poslishing Machine Can Save Material And Low Cost For Polishing. 1 Compatibility Of 0ther Equipments When We Designed This Polishing Machine, Taken Full Account Of The Consumables (Abrasive Film), Jig & Fixture Used Currently The Most Widely Used 127mm And Corner Positioning, Compression Work. Fixture Can Be With Other Manufacturers Equipment Exchange, And Do Not Make Any Adjustments. 2 Applies To A Wide Range Of Equipment, With No Need Of Any External Equipment, An Area Of Less Stable Production. As Long As Necessary In Accordance With The Replacement Of Fixtures, It Can Produce Different Types Of Connectors, Suitable For Production And Scientific Research Trial Orders. The Polishing Machine Is Versatile And Be Efficient And Fast Produced All Kinds Of Standard Fiber Optic Connectors Type With DedicatedFixture: Fc / Pc Fc / Apc Sc / Pc Sc / Apc St / Pc St / Apc Lc / Mu Mt-Rj 8 Deg. Or 0 Deg Mpo Mpx Mtp, E2000, D4 Etc Bd. In Addition, The Polishing Machine Is Able To Polish Sm, Mm And Pm Optical Fiber Connectors And Other Specialized Types. Special Circumstances, Can Be Customized According To User's Request Special Connector Fixture. This Equipment Can Be Used Not Only The Production Of Ceramic-Core Connector, The Same Can Be Used For Energy-Coupled Fiber-Optic Connector, Dark Fiber And The Optical Fiber Connectors Made Of Glass Or Plastic And Other Tiny Elements As Well And Production. 3 Operation Simple, Convenient To Simplify Production Processes, Improve Work Efficiency. Fixture Cleaning, Replacement Of Convenient And Quick. 4 Equipment Maintenance Equipment In The Use Of Easy Just To Avoid The Process Of Polishing Paste And Cleaning Of The Residue To Get Jig Polishing Machine Platform. 5 Connectors Produced By This Polishing Machine Are Of Low Insert Loss And Low Return Loss, Good Interchangeability And Good Repeatability. Our This Fiber Optical Polishing Machine Also Have Other Striking Strengths Such As: High Quality Reliability And Versatilit, Heat-Treated, Stainless Steel For Amazing Precision, Durability And Easy Operation. 6 Well-Chosen Polishing Films Can Improve Productivity, Lower Production Cost And Enhance Product Quality As Well.

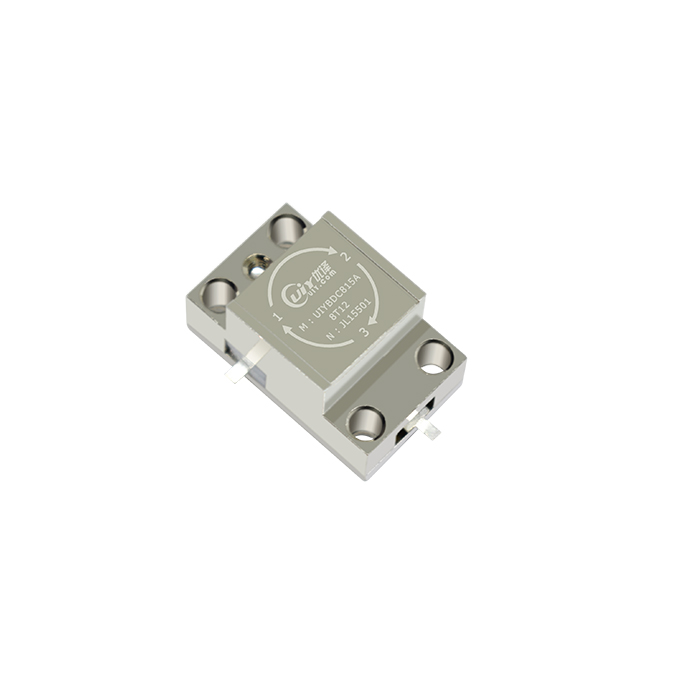

Pressure way4 coil springInsert Loss0.3 dB (SM)

0.2 dB (MM)polishing capacity(max)SC, FC, ST: 20, 48 units LC: 24, 48unitsReturn Loss50 dB (PC)

60 dB (APC)polishing connector typeFC, SC, ST, LC, MU, MTP, MPO, MTRJ and so onRadius10~25mmmotor speeed90rpm rotation, 2rpm revolutionOffset50 μ Mdimension230*230*255mmUnder cut50nmfilm size5' 'Repeatability0.1dBweight24KGInterchangeability0.2 dBInput voltage100-120VAC, 50/60Hz or 220-240VAC, 50/60HzWorking Situation Temperature-10_ +40º Cpolishing cycle2.83minsHeavy punch500g or 250gPolishing chassis diameter130mmPolishing time setting0-3minCounterweight pressure2.1~3.6kgf/cmTime Range0-300SPolishing Time2 min. (quick assembly type)3-4 min. (standard connectors)Pressure Range0~5kgPrecession Speed1.5rpm

Other supplier products

|

|

SC Fiber Optic Adapter With Shutters |

SC/UPC fiber optic adapters with shutterBrief IntroductionSC optical adapter is of flange type, single mode adapters are with zirconia sleeve . imp... |

|

|

Armored Cable Slitter |

Model:ACS Producing Area:Made in USA Key Features:

* Professional grade tool, ideal for slitting the corrugated copper, steel or aluminum armor ... |

|

|

FTTA LC RRU Armored Outdoor Fiber Patch Cable |

PDLC Waterproof fiber optic patch cord is standard size for Duplex LC Connectors, and he outer housing with metal protective device. The connecting... |

|

|

FC Fiber Optic Connctors |

FC Fiber Optic Connectors FC Fiber Optic Connector is comprised of a Nickel plated Brass body and a Ceramic ferrule/spring/crimp barrel assembly pl... |

|

|

OTB-0224 Fiber Termination Box |

Introduction Suitable for corridor, basement, room and building's outer walls application

With the function of mechanical splice, fusion splice, ... |

All supplier products

Same products