Blowout Preventor

Blowout Preventor(BOP)

Ram BOP

Single and double ram type BOPs are widely used in oilfield and offshore platform. They have the features of compact structure, easy handling and reliable seal. The pipe ram adopts the pressure increasing seal way, which makes it seal drill tool rapidly and efficiently, even remain its seal effect after the disappearance of fluid control pressure.

The open or close of ram preventor and ram replacing are both hydraulically controlled. The onsite replacing of pipe ram and sealing parts saves much time.

•Driving mode:Manual & hydraulic

•End connection:Flanged and bolted

•Working pressure:2000~10000PSI

•Nominal bore:90mm、120mm、179.4mm、279.4mm、346mm

•Executive standard: API 16A and relevant specification

Annular BOP

In case of blowout and well-sealing is needed,high pressure oil coming from control system enters the bottom closing chamber from bottom inlet to push piston moving upward.The movement of piston forces tubber core to move upward along the sphere surface, then supporting ribs get closer to push the internal rubber towards the wellhead center to fulfill the function of sealing drill equipment or the wellhead. When unlocking the seal is needed,hydraulic oil pushes the piston moving downward and the rubber core will reset to its original under its elastic force.

Structure Characteristics

1.The connection between top cap and housing ,top and bottom ends adopt flanges and bolts.

2.Semisphere rubber core has many advantages,such as not easy folding back, big volume of rubber storage.Under the well pressure,the piston pushes the rubber core upward to form a funnel shape.The funnel effect of rubber core increases its sealing performance and life span.

3.Characteristics of the sealing structure

The BOP has three important sealing positions:piston external surface seal,piston internal surface seal and mud blocking ring seal.Radial direction cross sectionof the piston comes of the shape"Z",which makes the piston have short stroke length,low height and big diameter.There are two wear-rings stick to the external surface of the piston and a wear-ring stick to the internal surface of the housing.The structure prevents metal to metal contact and protects piston and housing.

Other supplier products

|

|

Fishing Magnet |

The Fishing Magnets are used to retrieve all types of small objects having magnetic attraction from bore hole bottoms. Such undrillable objects as ... |

|

|

Valves |

Check Valve

Usually used for Kill Manifold

The sealing face of core and seat is overlaying-welded with hard alloy with erosion and corrosion resi... |

|

|

Jar Intensifier |

Jar Intensifier Type YJQ

Jar Intensifier Type YJQ is designed on the principle of compressible fluid. It is used in conjunction with Fishing Jar T... |

|

|

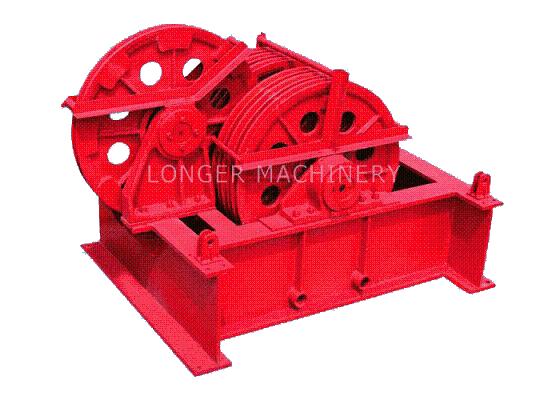

Crown Block |

The crown frame is made of high strength steel shapes.

Sheave grooves are hardened by medium frequency induction to provide extended service life.... |

|

|

Derrick (Mast) |

Derrick is divided into A, K, the tower type, masts and other types of packages.

1. A cross-section of a derrick thigh, such as rectangular or tr... |

All supplier products

Same products