Crawler cranes link KH180

1) Material:ofMnB35or40Mn2

2)heat treatment process:

Quenched:30-36HRC+treadIFquenching:48-54HRC

3)Processing: Millingside-drillscrewholes-redsquare- roughboring-heat treatment- Shot-testing-fineboring,endedmouthandchamfering

Other supplier products

|

|

cutting bladge |

cutting bladge TY140 |

|

|

Crawler cranes link KH180 |

1) Material:ofMnB35or40Mn22)heat treatment process: Quenched:30-36HRC+treadIFquenching:48-54HRC3)Processing: Millingside-drillscrewholes-redsquare-... |

|

|

Crawler crane track roller LS120 |

1.Material: Wheel:40Mn2axisofthebody: 50Mn Inside and outside thecover,shaft seat:QT450-10 Ironsets,bracket:QT450-10 Bush:CuPb10Sn102.Hea... |

|

|

shantui sd13 10Y-03B-01000 |

shantui sd13 10Y-03B-01000 |

|

|

Bucket teeth CAT320 |

1.Material:medium carbonalloy structural steel.2.Heat treatment:the overall quenching.46-52HRC.3.Casting Process:waxcasting.4.Shelf life:normal wea... |

All supplier products

Same products

|

|

Full automatic double end terminal crimping machine 2Pin flat wire |

Seller: 816004 |

product link:

Features

Full automatic terminalcrimping machine, using high-tech frequency con... |

|

|

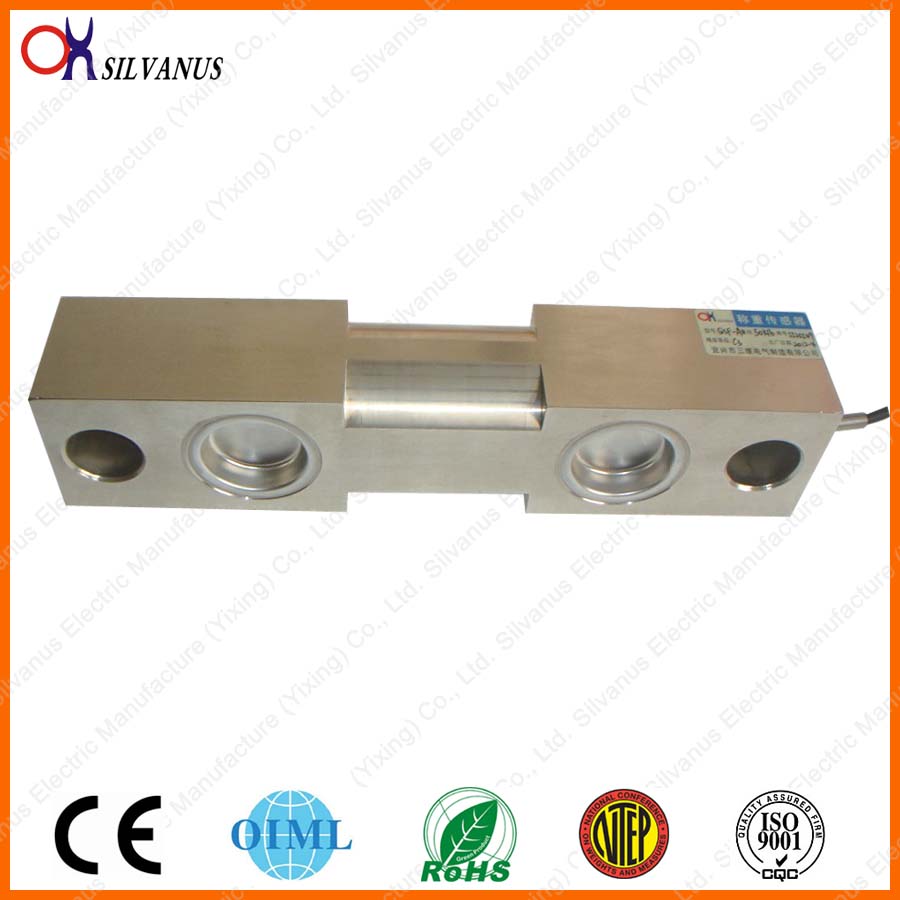

Bridge type Double Ended Shear Beam Load Cell QSF50~75klb weighing scales for electronic truck scale |

Seller: Yixing City Sanwei Electric Manufacturing Co., Ltd. |

Bridge type double shear beam, unique floating bearing structureSelf-resetting , good side force ... |

|

|

Weighing loadcell for silo loadcell 1t-20t |

Seller: Yixing City Sanwei Electric Manufacturing Co., Ltd. |

Fully compatible with Toledo FW weighing module;Rated load: 500kg ~ 20000kg;Unique structure, can... |

|

|

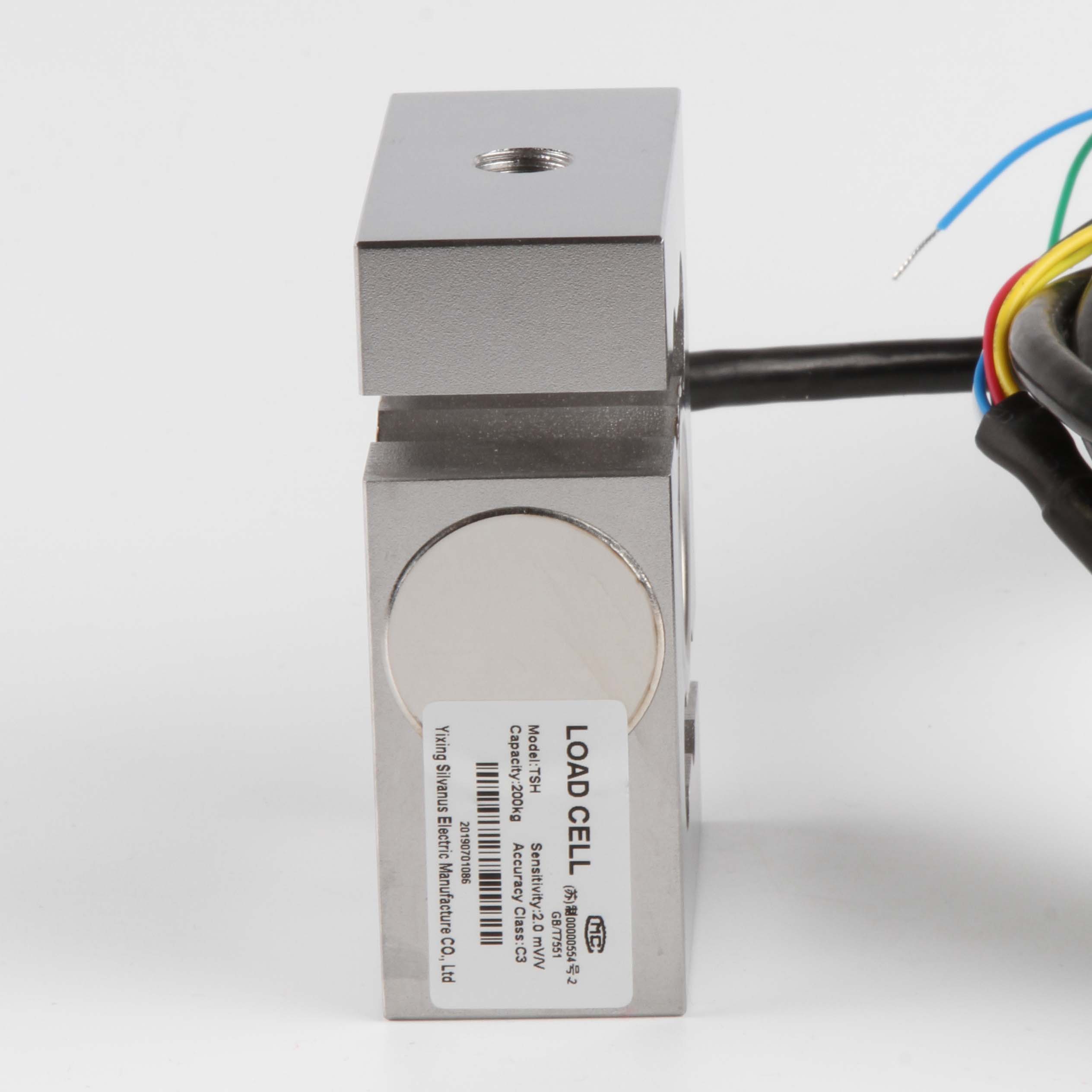

High Precision Alloy Steel 200 -5000kg S Type Load Cell for electromechanical scale , crane scale ,hopper scale |

Seller: Yixing City Sanwei Electric Manufacturing Co., Ltd. |

TSH steel "S" type weighing sensor, can withstand tension and external pressure, good output symm... |

|

|

300*300 square ceiling production line |

Seller: Foshan lesheng metal machinery co.,ltd |

|