OEM Robot Vacuum Cleaner Brands

OEM Robot Vacuum Cleaner Brands

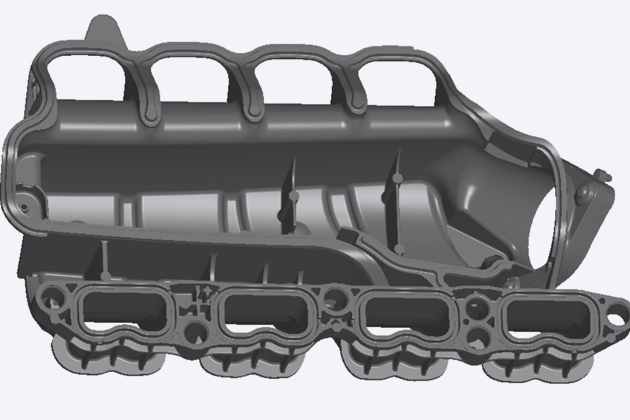

Injection Mold Manufacturing Services

has emerged as a cornerstone of modern industrial production. Its significance lies in the ability to produce complex, high-precision plastic components on a mass scale, satisfying the exacting requirements of industries ranging from automotive and electronics to consumer products and medical devices.

Understanding Injection Mold Manufacturing

Injection molding is a manufacturing process in which molten plastic is injected under high pressure into a precisely engineered mold cavity. Once the plastic cools and solidifies, the mold is opened and the part is ejected. This process enables the production of high-volume, identical components with excellent dimensional stability and repeatability.

Melted Polymer Injection: Thermoplastic resins or other polymers are heated to a fluid state.

High-Pressure Molding: Molten material is forced into a mold cavity at high pressures, ensuring the material fills every intricate detail.

Cooling and Ejection: The material cools rapidly, and the solidified component is ejected for further processing or assembly.

Efficiency in High-Volume Production: Multi-cavity molds allow simultaneous production of multiple parts per cycle.

High Tolerance Accuracy: The process yields parts that meet strict quality and dimensional specifications.

Material Versatility: A wide range of thermoplastics, elastomers, and even thermosets can be used.

Cost-Effective: Once the mold is developed, the per-unit cost decreases significantly with high production runs.

Technical Process and Engineering

Fundamentals of Injection Molding

At its core, injection molding involves heating polymer materials until molten and then injecting them under high pressure into a custom-designed mold. Once the plastic cools and solidifies, the mold opens, and the finished part is ejected. This cycle is repeated rapidly, often within seconds to minutes, enabling efficient mass production.

Advanced Mold Design and Fabrication

Design Engineering: Every successful injection molding project begins with detailed 3D modeling, simulation (such as mold flow analysis), and DFM (Design for Manufacturing) considerations. This phase optimizes part geometry and minimizes potential production issues.

Precision Tooling: Modern mold fabrication utilizes CNC machining, EDM (Electrical Discharge Machining), and laser technology to produce molds with tight tolerances. The material of the mold (typically aluminum for short runs and steel for long-term durability) is chosen based on production volume and required precision.

Complex Mold Technologies: Special molds—such as multi-cavity molds, high-speed molds, gas-assisted injection molds, and in-mold decoration molds—allow for enhanced production capabilities and creative design options.

Material Science and Selection

Thermoplastics and Engineering Plastics: Common choices include ABS, PE, PP, and high-performance engineering plastics. Material selection is critical to achieving desired mechanical, thermal, and aesthetic properties.

Specialty Materials: The use of elastomers, recycled polymers, and bio-based plastics is growing as manufacturers aim for performance while addressing environmental concerns.

Send product request

Other supplier products

| OEM Robot Vacuum Cleaner Brands | OEM Robot Vacuum Cleaner Brands Injection Mold Manufacturing Services has emerged as a cornerstone of modern industrial production. Its signi... | |

| Vietnam Injection Molding | Vietnam Injection Molding Plastic Injection Molding Services is the most cost-effective method for mass producing plastic parts. The injectio... | |

| Plastic Injection Molding Services | Plastic Injection Molding Services OEM Robot Vacuum Cleaner Brands The robot vacuum cleaner market has witnessed remarkable growth over the p... |

Same products

| Die Casting Molds | Seller: DONGGUAN KUASU MOLDTEC CO.,LTD | Die Casting Molds Die Casting Molds A is a tool for casting metal parts. It is a tool tha... | |

| Injection Molded Parts: A Complete Guide to Plastic Injection Molding | Seller: DONGGUAN KUASU MOLDTEC CO.,LTD | Injection Molded Parts: A Complete Guide to Plastic Injection Molding Plastic injection mold... | |

| High-Precision Machining Solutions for Your Manufacturing Needs | Seller: DONGGUAN KUASU MOLDTEC CO.,LTD | High-Precision Machining Solutions for Your Manufacturing Needs In the world of manufacturin... | |

| A world-renowned supplier of automotive interior and exterior parts | Seller: DONGGUAN KUASU MOLDTEC CO.,LTD | A world-renowned supplier of automotive interior and exterior parts Faurecia is a French aut... | |

| bespoke plastic moulding | Seller: DONGGUAN KUASU MOLDTEC CO.,LTD | bespoke plastic moulding Moldtec provides one-stop solutions for bespoke plastic moulding, c... |