Carbide Rod With Coolant Hole

Carbide Rods with One Coolant Duct

This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased heat during the high speed cutting or drilling. Standard specification and tolerance table please reference below.

|

Outer D(mm) |

OD Tol.(mm) |

Inner Hole d(mm) |

ID Tol.(mm) |

Hole center diviation value α |

Length(mm) |

L Tol.(mm) |

|

3.0 |

+0.50/+0.30 |

0.5 |

±0.10 |

0.10 |

330 |

+1.5 |

|

4.0 |

+0.50/+0.30 |

0.8 |

±0.10 |

0.10 |

330 |

+1.5 |

|

5.0 |

+0.50/+0.30 |

0.8 |

±0.10 |

0.13 |

330 |

+1.5 |

|

6.0 |

+0.50/+0.30 |

1.0 |

±0.15 |

0.15 |

330 |

+1.5 |

|

7.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

0.15 |

330 |

+1.5 |

|

8.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

0.15 |

330 |

+1.5 |

|

9.0 |

+0.60/+0.30 |

1.4 |

±0.15 |

0.20 |

330 |

+1.5 |

|

10.0 |

+0.60/+0.30 |

1.4 |

±0.15 |

0.20 |

330 |

+1.5 |

|

11.0 |

+0.60/+0.30 |

1.4 |

±0.15 |

0.28 |

330 |

+1.5 |

|

12.0 |

+0.60/+0.30 |

1.8 |

±0.15 |

0.30 |

330 |

+1.5 |

|

13.0 |

+0.70/+0.30 |

1.8 |

±0.15 |

0.34 |

330 |

+1.5 |

|

14.0 |

+0.70/+0.30 |

1.8 |

±0.15 |

0.37 |

330 |

+1.5 |

|

15.0 |

+0.70/+0.30 |

2.0 |

±0.20 |

0.40 |

330 |

+1.5 |

|

16.0 |

+0.70/+0.30 |

2.0 |

±0.20 |

0.40 |

330 |

+1.5 |

|

17.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

0.47 |

330 |

+1.5 |

|

18.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

0.50 |

330 |

+1.5 |

|

19.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

0.50 |

330 |

+1.5 |

|

20.0 |

+0.80/+0.30 |

2.5 |

±0.25 |

0.50 |

330 |

+1.5 |

|

21.0 |

+0.80/+0.30 |

2.5 |

±0.25 |

0.50 |

330 |

+1.5 |

|

22.0 |

+0.80/+0.30 |

2.5 |

±0.25 |

0.50 |

330 |

+1.5 |

|

23.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

24.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

25.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

26.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

27.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

28.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

29.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

30.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

Carbide Rodswith Two Coolant Ducts, Straight

This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased heat during the high speed cutting or drilling. Standard specification and tolerance table please reference below.

Standard pitch

|

Outside Dia. Ø(mm) |

OD Tol. (mm) |

Inner d(mm) |

ID Tol.(mm) |

Distance between holds |

Hole center diviation value α |

L mm |

Tol. (mm) |

|

|

mm |

Tol. (mm) |

|||||||

|

6.0 |

+0.50/+0.30 |

0.8 |

±0.10 |

1.5 |

﹢0/-0.20 |

0.15 |

330 |

+1.5 |

|

7.0 |

+0.60/+0.30 |

0.8 |

±0.10 |

1.5 |

﹢0/-0.20 |

0.15 |

330 |

+1.5 |

|

8.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

1.5 |

﹢0/-0.30 |

0.15 |

330 |

+1.5 |

|

9.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

2.6 |

﹢0/-0.30 |

0.20 |

330 |

+1.5 |

|

10.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

2.6 |

﹢0/-0.30 |

0.20 |

330 |

+1.5 |

|

11.0 |

+0.60/+0.30 |

1.2 |

±0.15 |

3.6 |

﹢0/-0.30 |

0.28 |

330 |

+1.5 |

|

12.0 |

+0.60/+0.30 |

1.2 |

±0.15 |

3.6 |

﹢0/-0.30 |

0.30 |

330 |

+1.5 |

|

13.0 |

+0.70/+0.30 |

1.2 |

±0.15 |

3.6 |

﹢0/-0.30 |

0.34 |

330 |

+1.5 |

|

14.0 |

+0.70/+0.30 |

1.5 |

±0.15 |

5.0 |

﹢0/-0.30 |

0.37 |

330 |

+1.5 |

|

15.0 |

+0.70/+0.30 |

1.5 |

±0.15 |

5.0 |

﹢0/-0.30 |

0.40 |

330 |

+1.5 |

|

16.0 |

+0.70/+0.30 |

1.5 |

±0.15 |

5.0 |

﹢0/-0.30 |

0.40 |

330 |

+1.5 |

|

17.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.30 |

0.47 |

330 |

+1.5 |

|

18.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.30 |

0.50 |

330 |

+1.5 |

|

19.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.30 |

0.50 |

330 |

+1.5 |

|

20.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

21.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

22.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

23.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

24.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.50 |

0.50 |

330 |

+1.5 |

|

25.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.50 |

0.50 |

330 |

+1.5 |

|

26.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.50 |

0.50 |

330 |

+1.5 |

Отправить запрос, связаться с поставщиком

Другие товары поставщика

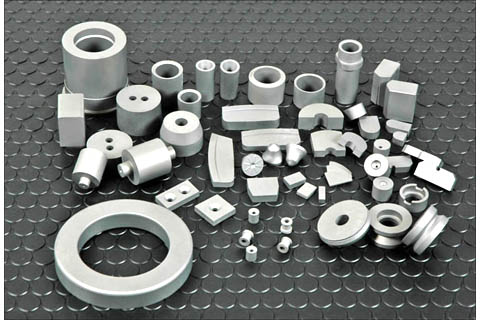

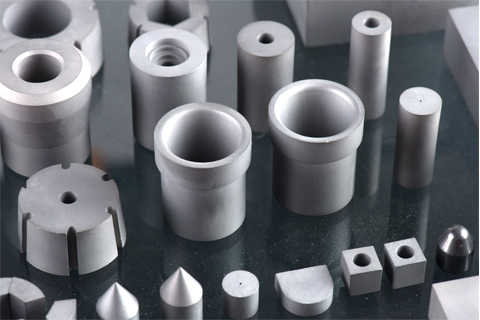

| Customized Tungsten Carbide Products | Introduction Toonney has a professional technical team, who can help to create new materials and find new way to produce difficult items base on y... | |

| Carbide Rod With Coolant Hole | Carbide Rods with One Coolant Duct This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased he... | |

| Sintering Furnance | IntroductionBase on years' experience and professional in manufacturing tungsten carbide materials, Toonney sintering furnace plant improves curren... | |

| Progressive Die/Punching Die | Introduction Tungsten carbide material is widely used in area where high wear resistance is required ,for example in drawing die, to draw copp... | |

| Carbide Cutting Tools | Introduction Carbide tools/ carbide cutter are usually used for cutting in machine manufacturing, so it also called carbide cutting tools. The ... |

Похожие товары

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Продавец: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Продавец: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... | |

| Horizontal Lathe | Продавец: Xilong (Shanghai) Machine Tool Co., Ltd. | As a professional horizontal lathe manufacturerand horizontal lathe factory, Sealion Machine Tool... | |

| Gantry Machining Center | Продавец: Xilong (Shanghai) Machine Tool Co., Ltd. | SEALION supplies Gantry Machining Center both tables moving type or gantry moving type. Gantry ty... | |

| Floor Type Boring Mill | Продавец: Xilong (Shanghai) Machine Tool Co., Ltd. | Floor Type Boring Mill is suitable for large size jobs to do milling, boring, drilling, etc. The ... |