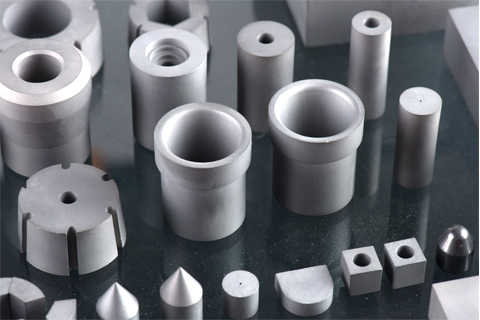

Carbide Rod With Coolant Hole

Carbide Rods with One Coolant Duct

This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased heat during the high speed cutting or drilling. Standard specification and tolerance table please reference below.

|

Outer D(mm) |

OD Tol.(mm) |

Inner Hole d(mm) |

ID Tol.(mm) |

Hole center diviation value α |

Length(mm) |

L Tol.(mm) |

|

3.0 |

+0.50/+0.30 |

0.5 |

±0.10 |

0.10 |

330 |

+1.5 |

|

4.0 |

+0.50/+0.30 |

0.8 |

±0.10 |

0.10 |

330 |

+1.5 |

|

5.0 |

+0.50/+0.30 |

0.8 |

±0.10 |

0.13 |

330 |

+1.5 |

|

6.0 |

+0.50/+0.30 |

1.0 |

±0.15 |

0.15 |

330 |

+1.5 |

|

7.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

0.15 |

330 |

+1.5 |

|

8.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

0.15 |

330 |

+1.5 |

|

9.0 |

+0.60/+0.30 |

1.4 |

±0.15 |

0.20 |

330 |

+1.5 |

|

10.0 |

+0.60/+0.30 |

1.4 |

±0.15 |

0.20 |

330 |

+1.5 |

|

11.0 |

+0.60/+0.30 |

1.4 |

±0.15 |

0.28 |

330 |

+1.5 |

|

12.0 |

+0.60/+0.30 |

1.8 |

±0.15 |

0.30 |

330 |

+1.5 |

|

13.0 |

+0.70/+0.30 |

1.8 |

±0.15 |

0.34 |

330 |

+1.5 |

|

14.0 |

+0.70/+0.30 |

1.8 |

±0.15 |

0.37 |

330 |

+1.5 |

|

15.0 |

+0.70/+0.30 |

2.0 |

±0.20 |

0.40 |

330 |

+1.5 |

|

16.0 |

+0.70/+0.30 |

2.0 |

±0.20 |

0.40 |

330 |

+1.5 |

|

17.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

0.47 |

330 |

+1.5 |

|

18.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

0.50 |

330 |

+1.5 |

|

19.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

0.50 |

330 |

+1.5 |

|

20.0 |

+0.80/+0.30 |

2.5 |

±0.25 |

0.50 |

330 |

+1.5 |

|

21.0 |

+0.80/+0.30 |

2.5 |

±0.25 |

0.50 |

330 |

+1.5 |

|

22.0 |

+0.80/+0.30 |

2.5 |

±0.25 |

0.50 |

330 |

+1.5 |

|

23.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

24.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

25.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

26.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

27.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

28.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

29.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

|

30.0 |

+0.80/+0.30 |

3.0 |

±0.25 |

0.50 |

330 |

+1.5 |

Carbide Rodswith Two Coolant Ducts, Straight

This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased heat during the high speed cutting or drilling. Standard specification and tolerance table please reference below.

Standard pitch

|

Outside Dia. Ø(mm) |

OD Tol. (mm) |

Inner d(mm) |

ID Tol.(mm) |

Distance between holds |

Hole center diviation value α |

L mm |

Tol. (mm) |

|

|

mm |

Tol. (mm) |

|||||||

|

6.0 |

+0.50/+0.30 |

0.8 |

±0.10 |

1.5 |

﹢0/-0.20 |

0.15 |

330 |

+1.5 |

|

7.0 |

+0.60/+0.30 |

0.8 |

±0.10 |

1.5 |

﹢0/-0.20 |

0.15 |

330 |

+1.5 |

|

8.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

1.5 |

﹢0/-0.30 |

0.15 |

330 |

+1.5 |

|

9.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

2.6 |

﹢0/-0.30 |

0.20 |

330 |

+1.5 |

|

10.0 |

+0.60/+0.30 |

1.0 |

±0.15 |

2.6 |

﹢0/-0.30 |

0.20 |

330 |

+1.5 |

|

11.0 |

+0.60/+0.30 |

1.2 |

±0.15 |

3.6 |

﹢0/-0.30 |

0.28 |

330 |

+1.5 |

|

12.0 |

+0.60/+0.30 |

1.2 |

±0.15 |

3.6 |

﹢0/-0.30 |

0.30 |

330 |

+1.5 |

|

13.0 |

+0.70/+0.30 |

1.2 |

±0.15 |

3.6 |

﹢0/-0.30 |

0.34 |

330 |

+1.5 |

|

14.0 |

+0.70/+0.30 |

1.5 |

±0.15 |

5.0 |

﹢0/-0.30 |

0.37 |

330 |

+1.5 |

|

15.0 |

+0.70/+0.30 |

1.5 |

±0.15 |

5.0 |

﹢0/-0.30 |

0.40 |

330 |

+1.5 |

|

16.0 |

+0.70/+0.30 |

1.5 |

±0.15 |

5.0 |

﹢0/-0.30 |

0.40 |

330 |

+1.5 |

|

17.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.30 |

0.47 |

330 |

+1.5 |

|

18.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.30 |

0.50 |

330 |

+1.5 |

|

19.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.30 |

0.50 |

330 |

+1.5 |

|

20.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

21.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

22.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

6.2 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

23.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.40 |

0.50 |

330 |

+1.5 |

|

24.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.50 |

0.50 |

330 |

+1.5 |

|

25.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.50 |

0.50 |

330 |

+1.5 |

|

26.0 |

+0.80/+0.30 |

2.0 |

±0.20 |

7.5 |

﹢0/-0.50 |

0.50 |

330 |

+1.5 |

Send product request

Other supplier products

| Heading Die | Introduction of Heading Die The application in cold heading die area is one of the main applications of tungsten carbide material. Heading die... | |

| Progressive Die/Punching Die | Introduction Tungsten carbide material is widely used in area where high wear resistance is required ,for example in drawing die, to draw copp... | |

| Drawing Die | Introduction ofDrawing Die Toonney tungsten alloy plant is a leading manufacturer of tungsten carbide alloy products. Tungsten alloy is a kind... | |

| Carbide Rod With Coolant Hole | Carbide Rods with One Coolant Duct This blank is specially for some CNC blades or drills which needs duct for coolant to cool the increased he... | |

| Solid Carbide Rods | Introduction of Solid Carbide Rods Solid carbide rod is mainly made of tungsten carbide, binder metal cobalt and some other functional ingredi... |

Same products

| The Ultimate Tool for Bubble-Free Displays | Seller: Shenzhen Wikshu Technology Co. | FORWARD FW-16R Bubble Remover and FW-8R Mini Bubble Removal Machine removes screen OCA bubbles du... | |

| Precision CNC Lathe With Conjoined Oblique Rail Cutter Tower | Seller: Zhejiang Guoyu CNC Machine Tool Co., Ltd. | Technical Characteristics: 45° slant bed base structure, with strict aging treatment, smooth ... | |

| Rail Welder A Frame aligners railway welding tools | Seller: 834406 | 产品描述 A型车架 A-Frame 是一种导轨对准器,可精确对准要焊接的导轨。该设备在焊接操作期间将导轨固定到位。 | |

| 2 parts fluid mixing dispenser 2 component dosing epoxy PU silicon rubber vacuum system | Seller: 824681 | What is the difference between 2K AB adhesive materials manual potting machine and robot pottingm... | |

| Horizontal Machining Center | Seller: Xilong (Shanghai) Machine Tool Co., Ltd. | Horizontal Machining Center parts can automatically finish four sides milling, boring, drilling, ... |