Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02

During the processing of bearing rings, various defects are often generated on the surface or inside, andcrack testing equipmentoccupy a large proportion of all defects.

The cause of the cracks in the bearing rings is complicated. From the raw materials to the finished products of the ferrules, if the process is not proper, the cracks may be directly caused or the hidden cracks may be buried for the occurrence of the lap ring grinding cracks.

There are many ways to form cracks in bearing rings: Raw material defects include: cracks in raw materials and the effects of raw material defects on the grinding process.

Forging defects include forging cracks, effects of forged microstructure defects on the grinding process, and cutter cracks. There are also various heat treatment defects and the like. Therefore, crack detection and hardness testing are essential. BKNhas considerable experience in crack detection, and Bearing Ring Crack and Hardness Combination testing equipment is a perfect combination.

Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 Brief Introduction

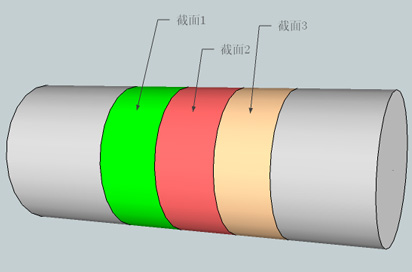

Detection process

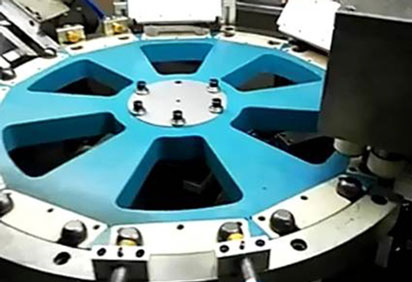

Vibrating plate and string charging →hardness test→crack detection→automatic blanking

↓

Bad product sorting

Automatic charging —automatic detection—automatic sorting —automatic blanking

Crack sensitivity: a crack with a depth of ≥0.05 mm and a length of ≥1 mm extending inward from the surface of the ferrule; for a crack that has not extended to the surface inside the ferrule, when the thickness between the subcutaneous surface and the surface of the workpiece is ≤0.2 mm, the depth is ≥0.20 mm Cracks of length ≥ 1 mm can be detected.

Hardness sensitivity: Rockwell 1HRC ~ 2HRC (other parameters remain stable and consistent).

Nanjing BKN Automation System Co., Ltd. is an non destructive testing equipment manufacturersand has long been committed to the development and production of bearing hardness and crack eddy current screening equipment.

Send product request

Other supplier products

| Bearing Ring Crack and Hardness Combination Flaw Detector TQJC-02 | During the processing of bearing rings, various defects are often generated on the surface or inside, and cracks occupy a large proportion of all d... | |

| Portable Magnetic Flux Leakage Testing Equipment | Magnetic flux leakage test refers to the formation of a leakage magnetic field on the surface of a test piece after it is magnetized due to defects... | |

| Wireless Transmission Steel Bar Ultrasonic Flaw Detector | Steel bar is a conventional product with high density, moderate noise. The system is suitable for the automatic detection of internal and external ... | |

| QTXET-01 Ball Studs Eddy Current Sorting Machine 1024 | There are two main types of ball studs: one is a combination of a spherical pin and an integral ball seat, and the other is a combination of a hemi... | |

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKN Automation System Co., Ltd. for maki... |

Same products

| Micronized polypropylene wax for injection moulding | Seller: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Seller: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |