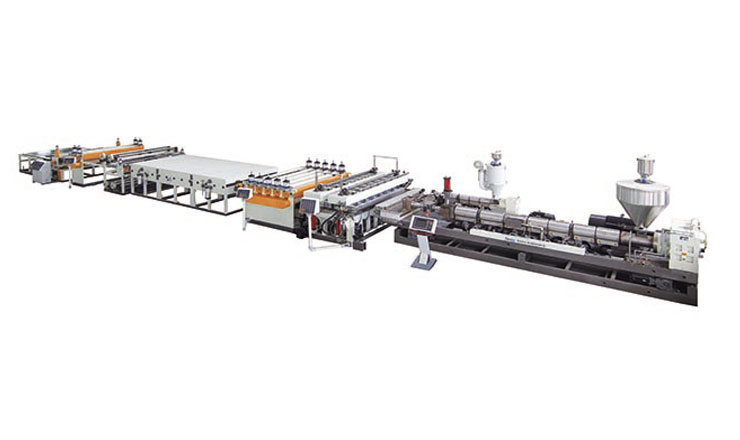

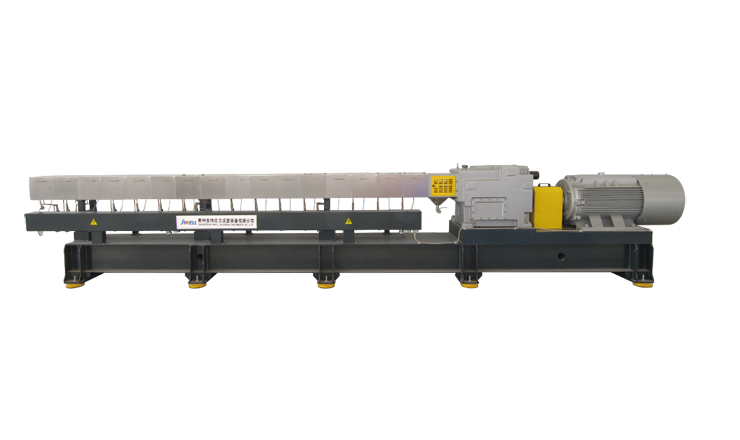

Co-rotating Twin Screw Extruder CJWV Large Volume Series

Main Parameters for CJWV Large Volume Series Twin Screw Extruders, CJWV series twin-screw extruder which is defined as deep groove type and has larger free volume. This machine applicaton to high filling etc., co rotating twin screw extruder has the charastics of high efficency, high capacity and running stable and well received our customer high praise.

According to the PU/TPU raw material rheological speciality. Our co rotating twin screw extruder manufacturersmade a lot of efforts on the barrel processing accuracy and barrel cooling effect. Meanwhile, we updated and redesigned the core parts, so that we basically solved some bottleneck problems in the production process. The reaction efficiency and output capacity have been improved sharply and customers approve it.

Description About Co-rotating Twin Screw extruder

|

Item |

Description |

|

Place of origin |

China |

|

Brand name |

JWELL |

|

Model number |

CJWS-95 |

|

Capacity |

1200kg/hr |

|

Packaging details |

Wooden pallet packing |

|

Delivery time |

90days |

|

Payment terms |

Specifications of Co-rotating Twin Screw extruder

|

Technical parameters |

||||||

|

Model |

Diameter |

L/D |

Screw speed |

Motor Power |

Specific torque |

Capacity Range |

|

mm |

rpm/min |

KW |

T/A3 |

kg/hr |

||

|

CJWV44 |

24~68 |

600 |

37 |

150~300 |

||

|

800 |

55 |

220~440 |

||||

|

CJWV55 |

24~68 |

600 |

55 |

300~600 |

||

|

1000 |

90 |

440~880 |

||||

|

CJWV66 |

64 |

24~68 |

600 |

110 |

530~1060 |

|

|

900 |

160 |

740~1480 |

||||

|

CJWV77 |

74 |

24~68 |

600 |

200 |

800~1600 |

|

|

900 |

280 |

1000~2000 |

||||

|

CJWV86 |

24~68 |

600 |

280 |

1100~2200 |

||

|

800 |

400 |

1600~3200 |

||||

|

CJWV100 |

96 |

24~68 |

600 |

400 |

1800~3600 |

|

|

800 |

560 |

2000~4000 |

||||

|

CJWV110 |

24~68 |

600 |

630 |

2200~4400 |

||

|

700 |

730 |

3000~6000 |

||||

|

CJWV125 |

123 |

24~68 |

500 |

800 |

3000~6000 |

|

|

600 |

900 |

3600~7200 |

||||

|

CJWV140 |

24~68 |

500 |

1100 |

3200~6400 |

||

|

600 |

1300 |

4000~8000 |

||||

Co-rotating Twin Screw extruder Application

Co-rotating Twin Screw extruder Application

Thermoplastic Elastomers Series:

Thermoplatics are the most potential new material at present, combining both advantages of plastic and rubber, which can be used in automobile, electronics, engineering and medical, etc.

TPS

TPU

TPV

TPEE

TPO

Silicone Adhesive Series:

Silicone adhesive serial equipment has been always one of our superior products, on base of years of technology accumulation and customers' feedback, the silicone equipment became the competitive products with proven technique, steady running, and good reputation.

Co-rotating Twin Screw extruder Performance and Advantages

Deceleration system:

Special gearboxes for jwell extrusion machinery are used. The transmission parts are made of high-quality, super-high alloy carburized steel, combined with carburizing, quenching, and gear grinding processes. The key parts have increased surface strengthening treatment, tooth surface strength HRC54-62, core The hardness is HRC30-40, and the gear is grade 6. The system has the characteristics of high speed, high torque, low noise, and so on.

Feeding system:

The double-screw with agitator quantitative feeding system is adopted, and the feeding is uniform and accurate, and there is no phenomenon of racking.

Electric control system:

Imported electrical components are used. The control panel is a man-machine interface. Each part of the equipment adopts "module" control (also can be configured according to user requirements). The multi-functional module has a clear structure and has safety interlocking devices (such as lubrication loss-of-pressure protection, machine head Pressure protection, over-current protection, etc.), truly reflect the operating conditions of the equipment, accurate control, high sensitivity, and convenient operation.

JWELL Extrusion Machinery Co. Ltdis a high-tech manufacturer specializing in the research and development of yarn spinning machines, we provide Jwell machinery, pet sheet extrusion line, etc. Contact us to know more.

Send product request

Other supplier products

| PP Hollow Sheet Extrusion Line | Jwell hollow plates are as follows: PP Hollow Building Formwork Double Out Extrusion Line: PP hollow building template the first mock exam do... | |

| HDPE Blow Molding Machine | HDPE Blow Molding Machine JWELL Extrusion Machinery Co., Ltdis one of the leading HDPE blow molding machine manufacturersand blow molding machin... | |

| Plastic Compounding Machine | Plastic Compounding Machine The twin-screw extruder is composed of a transmission device, a feeding device, a barrel, and a screw, and the funct... | |

| HDPE Blow Molding Machine | JWELL is one of the leading HDPE blow molding machine manufacturersand blow molding machine suppliersin China. The HDPE blow molding machine, also ... | |

| Film Extrusion Line | Film extrusion lineis a kind of screw plastic film extruder. The working mechanism of screw plastic extruder is to fully plasticize the materials b... |