BKNET-0102 Welded Pipe Eddy Current Flaw Detector

Eddy current weld inspectionis the use of eddy current technology to test the welded pipe, this type of testing is based on the premise of lossless. At the same time, we need to be clear that the welded pipe is, in general, the steel pipe that we usually say, which is a welded steel pipe.

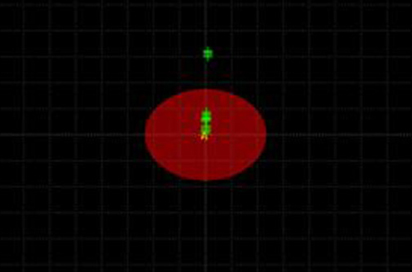

Eddy current testing of weldsis a non-destructive testing technique for detecting component defects by using the principle that the eddy current induced by the AC electromagnetic coil on the surface of the metal member encounters a defect. The oscillating current is generated in the conductive member by the excitation coil by the principle of electromagnetic induction, and the amount of change in the eddy current is measured by the detecting coil, thereby obtaining information on the component defect.

Eddy current weld testingis a non-destructive testing technique in which an alternating current electromagnetic coil induces eddy currents on the surface of a metal member. It is suitable for the detection of defects in conductive materials, including ferromagnetic and non-ferromagnetic metal materials.

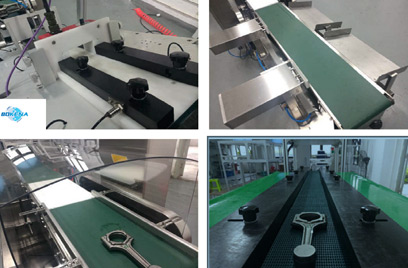

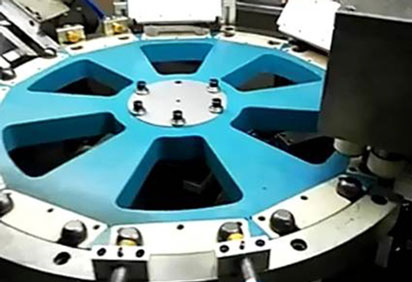

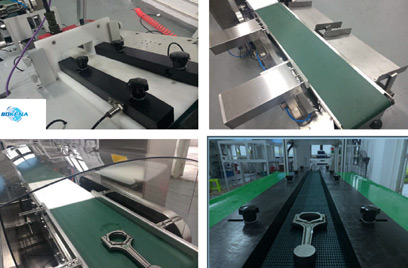

BKNET-01�2 NDT weld testing equipmentis used for on-line and off-line inspection of welded pipes. It has high sensitively to axial defects such as unwelded welding, dark spots and open cracks. In the production process, products are caused by welder failure. Slow and long-term injuries can be reliably detected.

BKNET-0102 Welded Pipe Eddy Current Flaw Detector performance

|

Detection channel |

Double channel |

|

Detection speed |

1~500m/min(online) |

|

Frequency range |

100Hz-1MHz |

|

Gain |

0~99dB,step0.1dB |

|

Phase rotation |

0-360°step1° |

|

High pass |

|

|

Low pass |

1Hz~10000Hz |

BKNET-0102 Welded Pipe Eddy Current Flaw Detector Features:

High precision end and end-to-tail signal removal

High precision real-time, delayed alarm output

Fast digital/analog electronic balance

Memory track delay blanking function

Non-equal amplitude phase/amplitude alarm domain

Remote automatic help system

Synchronous alarm output for internal and external clock control

As one of non destructive testing equipment suppliers, we can offer types of eddy current testingproducts for sale, if you have needs, please contact us.

Send product request

Other supplier products

| RQ-120-B Automatic CNC EDM Notch | "RQ-120-B Electric Pulse Automatic CNC EDM notches" is a precise instrument specially developed by Nanjing BKNAutomation System Co., Ltd. for makin... | |

| EDM Notch | An electric pulse is a pulse generated by electrons, and a pulse is a process of changing a voltage in a short time. Electropulsing is an unsteady ... | |

| QTXET-01 Ball Studs Eddy Current Sorting Machine 1024 | There are two main types of ball studs: one is a combination of a spherical pin and an integral ball seat, and the other is a combination of a hemi... | |

| Bolt Eddy Current Sorter BKNFX-11 | The technology of BKNoriginated from eddy current Laboratory of Institute of Materials, Nanjing University of Technology. At present, it is a leadi... | |

| Eddy Current Testing Equipment | Bokena is one of the most professional eddy current test equipment suppliersin China. We have been devoted to produce ect testing equipmentand ect ... |

Same products

| Micronized polypropylene wax for injection moulding | Seller: Syntop chemical Co.,Ltd. | The incorporation of polypropylene micronized wax into injection moulding processes delivers the ... | |

| Drum Type Mobile Mixing Station | Seller: Yousheng Machinery Equipment Co.,Ltd | Drum Type Mobile Mixing Station Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan... | |

| Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay | Seller: XIUCHENG RFID | Size:On request Material:PET, PVC,paper or customized Frequency:UHF/HF Printing:Thermal transf... | |

| Micronized wax used for industrial paint processing | Seller: Syntop chemical Co.,Ltd. | Micronized wax is a vital functional additive in industrial paint processing, with primary functi... | |

| Plant Growth Regulator Manufacturer | Seller: HEBEI LAIKE BIOTECH CO.LTD | Plant Growth Regulator Manufacturer Plant Growth Regulator Manufacturer - Laike Biotech spec... |