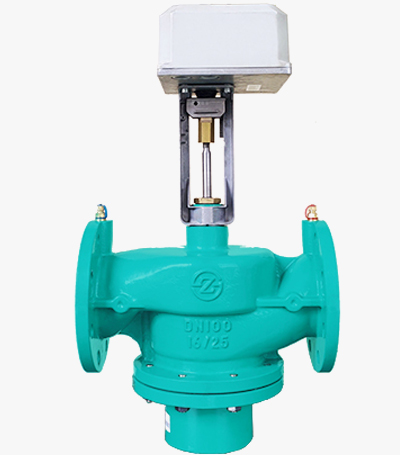

Electric Ball Valve

Categories: Ball Valve, Ball Valve By Drive Mode, Forged Ball Valve

Tags: Ball Valve Electric, Electric Actuated Ball Valve, Electric Actuator Ball Valve, Electric Ball Valve, Electrical Ball Valve, Electrically Actuated Ball Valve, Electronic Ball Valve, Motorised Valve, Motorized Ball Valve, Motorized Valve

Description

Electrically operated valves use an electric actuator to rotate a ball with a hole in the center to control flow.

What is an Electric Ball Valve?

ZECO 3 inch electric ball valveis named after the combination of an electric actuator and ball valve. It is usually used in medium pipelines requiring remote switch and adjustment control. It is an important control product in industrial automation control. ZECO’s electric actuators are usually equipped with German AUMA electric actuators. If customers have other requirements, ZECO Valve companycan also customize them according to customers’ requirements. 2 inch electric ball valve is one of the common types of the electrically operated ball valve.

How does an Electrical Ball Valve work?

Generally, electric ball valves convert the electrical energy into rotary force using the electric motor thus turning ball valves. It is the most efficient mode of controlling valves due to the clean electric energy and quiet mode of turning valves.

To understand it better, here is how the electric ball valve works.

Step One: Powering Up the System

First, you will switch on the electric ball valves to allow the proper flow of electric current through the system. Electric current will power the electric motor which will generate a torque transmitted by a shaft connected to the valve stem.

You will realize that the ball valve begins to rotate due to action from the shaft and the electric motor. The amount of power that you need to control the operations of the electric ball valve will vary accordingly.

You may need 12V, 24V, and 48V of direct current to help in controlling the electric ball valve. On the other hand, you may also use 24V, 48V, 120V, 130V, and 240V of alternating current to control the valve.

Step Two: Controlling the Torque

As the power flow through the motor, you can control the force that the motor will produce to rotate the ball valve. It has a system of different gears which help in controlling the shaft thus producing different levels of force.

You can decide on the gear that will produce the best of forces that can control the electric ball valve accordingly. The speed at which the electric ball valve will operate is inversely proportional to the torque f the electric ball valve.

Features of Electric Ball Valves:

ZECO is committed to the premise that the products meet international standards, and do its best in the company’s research and development, so as to minimize the cost to users. Therefore, as one of china ball valve suppliers, ZECO made great efforts in ball valve torque, and finally developed a product with lower torque than the ball valve on the market, so that it can be equipped with an electric actuator with lower first gear torque to reduce user costs;

ZECO electric ball valve is available in full size and reduced size series to meet different requirements of customers. Full bore ball valves are provided in the same channel as the inner diameter of the pipeline for minimal fluid resistance and easy pipeline cleaning. The weight of reduced diameter ball valves is only about 70% of the same diameter full bore ball valve, which can effectively reduce the cost and price, while the fluid resistance coefficient is only about 1/7 of the same diameter globe valve;

ZECO electric actuated ball valve ensures reliable sealing under high, low, and vacuum conditions;

ZECO electric ball valve with automatic pressure relief structure, when the pipeline pressure abnormal rise, the chamber medium can rely on its own thrust to push the seat and automatic pressure relief.

Applications of Electric Actuated Ball Valves

Food Service Equipment

Irrigation Industry

Vehicle Wash Systems

Water Treatment Equipment

Manufacturing Facilities

Mobile Applications

Heat Exchangers

How to Install an Electric Ball Valves?

When you’re mounting electric valve actuators in place, use sturdy, industry-standard parts. Many actuators and mounting hardware use the ISO 5211 standards for connections, which ensures various brands and components work together seamlessly.

You’ll need at least three components for mounting:

An output drive

A stem to connect to the valve head

A flange that mounts the actuator onto the valve

Various actuators require different types of flanges based on the torque and fasteners available.

Material of Electrically Opened Ball Valve:

|

No |

Part |

Material |

|

1 |

Body |

ASTM A105 |

|

2 |

Bonnet |

ASTM A105 |

|

3 |

Ball |

ASTM A105 |

|

4 |

Seat |

ASTM A105 + PTFE |

|

5 |

Stem |

ASTM A182 F6a |

|

6 |

Anti-static Device |

SS304 |

|

7 |

Gasket |

Graphite + SS304 |

|

8 |

Bolt |

ASTM A193 B7 |

|

9 |

Nut |

ASTM A194 2H |

|

10 |

O-ring |

Viton A |

|

11 |

Electric Actuator |

ASTM A182 F304 |

What Causes Failure in Electrical Ball Valve?

Poor Design of the Electric Ball Valve

You may have a very poor design of the electric ball valve that may fail to work with the application requirements. The poor design may be in terms of poor chemical compatibility, and poor rating on flow or pressure rate.

Faulty Installation

You may also experience failure in successful operations, which may come as a result of poor or faulty installations. There may be leakages or wrong position of the electric ball valves thus leading to their eventual failure.

Improper Operations

In addition to the above contributors, you may also have improper operations for the electric ball valves. In other words, you may use the electric ball valves for the wrong operations thus leading to complete failure.

Send product request

Other supplier products

| Wafer Check Valve | The double plate wafer check valveis used for the pure pipeline, industry, environmental protection, water treatment, high-rise building water supp... | |

| 12″ Butterfly Valve | Categories: Butterfly Valve, Butterfly Valve By Inch Description Butterflly valve 12 inch means the valve size is 12 inch, and in DN it is DN30... | |

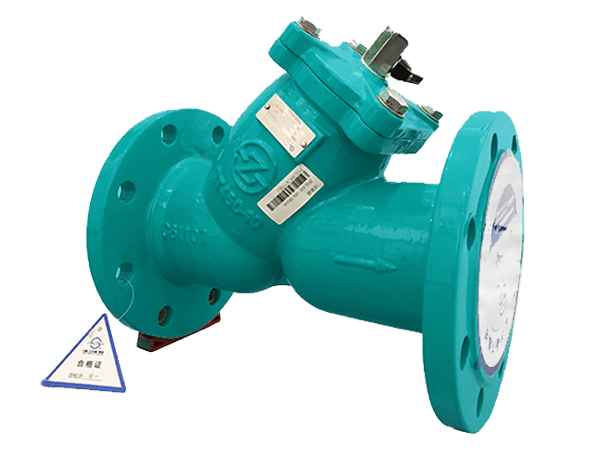

| Pressure Independent Control Valve | Features of Pressure Independent FlowControl Valve Flow regulation and hydraulic balance are integrated; The self-acting diaphragm differenti... | |

| Strainer & Dirt Separator | Strainers, dirt separators and backflow preventers are designed to prevent impurities from entering the specified pipe section. Comparing these thr... | |

| Gate Valve | ZECO is one of the professionalgate valve manufacturing companies, specializing in the production of wedge gate valve and through conduit gate valv... |