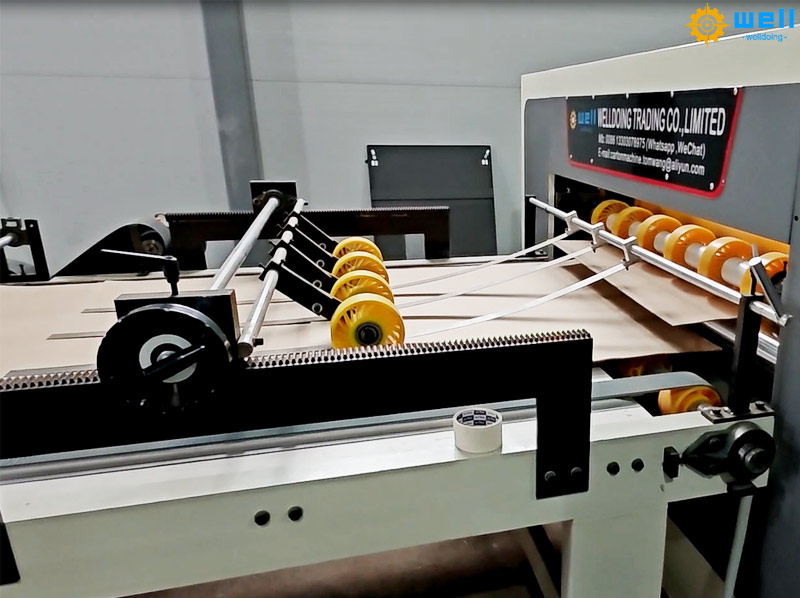

1400 mm industrial paper automatic hardboard production line

The1400 mm industrial paper hardboard production lineis suitable for combining 80-600g / m2 grey board with 2,3 and 5 layers with the required thickness and specifications. The production line has many characteristics, such as reasonable design, compact structure, convenient operation and maintenance, and energy saving. The production line also makes up for the single manual pasting and other characteristics, greatly reduce the production cost, improve the product quality, the cardboard flatness, strength, adhesion force have been greatly improved, is the ideal equipment for you to make cardboard.

Main technical description ofautomatic paper hardboard production line

1. Design speed: 100m / min Working speed: 50-90m / min

2. Working width: 1400mm

3. Suitable for paper: 75g~650g all kinds of high school grade roll paper

4. Production line length: about 65 meters (the specific length is subject to the foundation drawing)

5. Equipment footprint: 68m×6m×4.5m (length, width and height)

6. Equipment flow direction: determine the left or right position on the control side according to the user workshop.

| Production of cardboard width | ≤ 1600mm |

| Production speed | 0-30m/min |

| Paper layers | ≤ 6 layers |

| Cutting thickness | ≤ 5mm |

| Total power | 60KW (including heating and drying) |

| Normal power | 40KW |

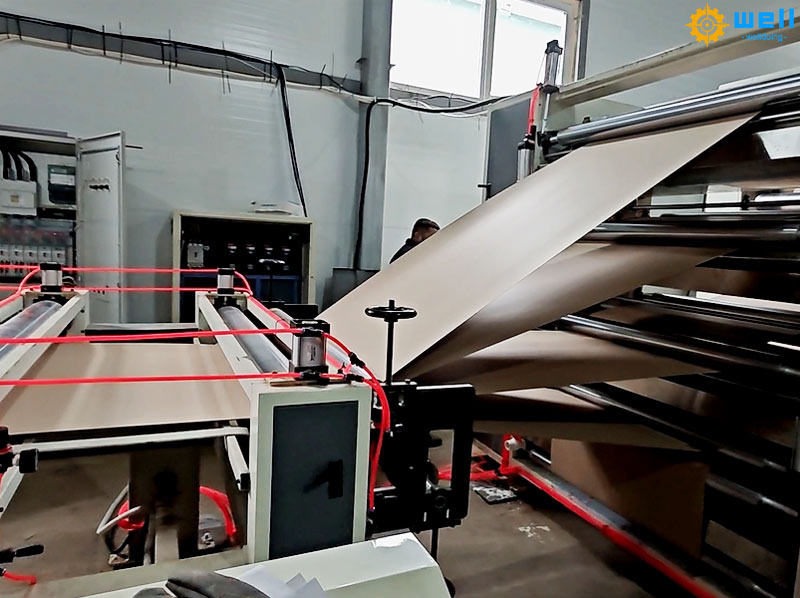

This is our5 ply paper hardboard production linein Russia.

Customers visit our machines

FAQ

1. Are you a factory or trading company?

We are both a factory and a trading company in this field .

2. What is the terms of payment you accept?

We usually accept the T/T payment, we need 30% of total amount as deposit,

pay the 70% balance before delivery, but we can also accept the L/C.

3. How does your factory do regarding quality control?

Quality is priority. We always regard great importance to quality controlling fromthe very small thing(even a small screw we will choose the best quality) from thebeginning.

If you are also interested in this machine,please don’t hesitate to contact us:

Overseas manager: Tom Wang

Phone/

Send product request

Other supplier products

All supplier products

Automatic carton folder gluer stitching machine

Automatic carton folder gluer stitching machine

A. Paper feeding department:Adopt SiGreen high wear-resistant suction belt, each can control the s...

3 color flexo printer slotter die cutter machine

Functional features:

1. The advanced adsorption leading edge paper feeding system has the advantages of simple operation, high speed and high prec...

1400 mm industrial paper automatic hardboard production line

The1400 mm industrial paper hardboard production lineis suitable for combining 80-600g / m2 grey board with 2,3 and 5 layers with the required thic...

China EPE Foamed Tube making Machine

ChinaEPE foamed tube making machineitself cannot produce bubbles out of thin air. It introduces butane into the barrel, which is fully mixed and ex...

paper angle edge corner cardboard protector making machine

Product Description

1)Paper Angle Board Machine is a kind of machine that specializes in the production of paper corner. It is generally composed ...

Same products

Micronized polypropylene wax for injection moulding

Seller: Syntop chemical Co.,Ltd.

The incorporation of polypropylene micronized wax into injection moulding processes delivers the ...

Drum Type Mobile Mixing Station

Seller: Yousheng Machinery Equipment Co.,Ltd

Drum Type Mobile Mixing Station

Drum Type Mobile Mixing StationPortable Drum Concrete Batch Plan...

Washable Cheap 13.56Mhz 213 Nfc Mini Stickers 13.56 Mhz RFID Label Sticker Tag HF/UHF Tags Dry Inlay

Seller: XIUCHENG RFID

Size:On request

Material:PET, PVC,paper or customized

Frequency:UHF/HF

Printing:Thermal transf...

Micronized wax used for industrial paint processing

Seller: Syntop chemical Co.,Ltd.

Micronized wax is a vital functional additive in industrial paint processing, with primary functi...

Plant Growth Regulator Manufacturer

Seller: HEBEI LAIKE BIOTECH CO.LTD

Plant Growth Regulator Manufacturer

Plant Growth Regulator Manufacturer - Laike Biotech spec...