Color PEEK R&D Series

PEEK ColorR&D Series can be customized according to the customer's own demand. Different PEEK plastic colorscan be chosen for our PEEK raw material. Having good thermal stability, color consistency, high purity, and high-temperature resistance, our PEEK material colorR&D series is just as high quality as other naturalPEEK materialseries.

PEEK Material Color R&D Series Specifications

|

Material Properties |

Test Method |

Conditions |

Units |

770G |

|

Mechanical Data |

||||

|

Tensile Strength |

ISO 527 |

B reak,23℃ |

MPa |

- |

|

Y ield,23℃ |

MPa |

100 |

||

|

Tensile Elogation |

ISO 527 |

Break,23℃ |

% |

45 |

|

Flexural Strength |

ISO 178 |

Break,23℃ |

MPa |

- |

|

Y ield,23℃ |

MPa |

165 |

||

|

Fleoural Modulus |

ISO 178 |

23℃ |

Gpa |

|

|

Compressive Strength |

ISO 604 |

23℃ |

MPa |

125 |

|

Charpy Impact Strength |

ISO 179/leA |

Notched |

kJm-2 |

7 |

|

ISO 179/IU |

Unnotched |

kJm-2 |

- |

|

|

Izod Impact Strength |

ISO 180/A |

Notched |

kJm-2 |

|

|

ISO 180/U |

Unnotched |

kJm-2 |

- |

|

|

Mould Shrinkage |

ISO 294-4 |

Along flow |

% |

1 |

|

Across flow |

% |

|||

|

Thermal Data |

||||

|

Melting Point |

ISO 11357 |

℃ |

343 |

|

|

Glass Tansition (Tg) |

ISO 11357 |

Onset |

℃ |

143 |

|

Special Heat Capacity |

DSC |

23℃ |

kj kg-1℃-1 |

|

|

Coefficient of Thermal Expansion |

ISO 11359 |

Along flow below Tg |

ppm K-1 |

45 |

|

Along flow above Tg |

ppm K-1 |

120 |

||

|

Heat Deflecion Temperature |

ISO 75A-f |

℃ |

152 |

|

|

Thermal Conductivity |

ASTM C177 |

23℃ |

W m-1K-1 |

|

|

Flow |

||||

|

MeltIndex |

ISO 1133 |

380℃,5kg |

g10min-1 |

10 |

|

Miscellaneous |

||||

|

Density |

ISO 1186 |

Crystalline |

gcm-3 |

|

|

Amorphous |

gcm-3 |

|||

|

Shore D Hardness |

ISO 868 |

23℃ |

85 |

|

|

Water Absorption(3.2mm thick Tensile Bar) |

ISO 62-1 |

24h,23℃ |

% |

|

|

by immersion |

Equilib riu m,23℃ |

% |

||

|

Electrical Data |

||||

|

Dielectric Strength |

IEC 60243-1 |

2mm |

kV mm-1 |

23 |

|

Comparative Tracking Index |

IEC 60112 |

V |

150 |

|

|

Dielectric Constant |

IEC 60250 |

23℃,1kHz |

||

|

23℃,50kHz |

3 |

|||

|

Loss Tangent |

IEC 60250 |

23℃,1MHz |

||

|

Volume Resistivity |

IEC 60093 |

23℃,1V |

Ω cm |

10 16 |

|

275℃ |

Ω cm |

10 9 |

||

More types of peek composite material, please visit our website.

Send product request

Other supplier products

| CA Series-770CA30 PEEK Carbon Fiber Reinforcement | CA Series-770CA30 carbon fiber filled peekreinforcement is widely used in automobile and aviation fields. It is widely used in automobile fuel pump... | |

| PEEK Valve in Home Appliances | PEEK Valvein Home Appliances PEEK has good wear resistance, self-lubrication, non-toxicity, high-temperature resistance, low density, and can de... | |

| Color PEEK R&D Series | PEEK ColorR&D Series can be customized according to the customer's own demand. Different PEEK plastic colorscan be chosen for our PEEK raw mate... | |

| PEEK Seal Material in Mechanical | PEEK Seal Materialin Mechanical PEEK is a kind of mateiral with both rigidity and toughness, excellent mechanical properties, wear resistance, s... | |

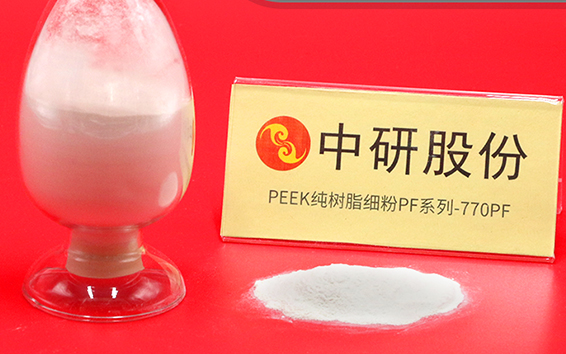

| Grade PF PEEK Pure Resin Fine Powder | The material is obtained by grinding the coarse powder (D50 is 13 micron ~ 75 microns) . It can be used as moulding material, spraying material and... |

Same products

| Oxytetracycline Hydrochloride Soluble Powder Factory | Seller: Hebei Shengxue Dacheng Pharmaceutical Co., Ltd. | Oxytetracycline Hydrochloride Soluble Powder is a broad-spectrum antibiotic used to treat a varie... | |

| Anti-mold for Furniture | Seller: KOBSO (CHINA) LIMITED | Anti Molds for Cabinet As a experienced supplier in this field for over 10+ years, Kobso Multi-f... | |

| Anti-mold for Clothes | Seller: KOBSO (CHINA) LIMITED | In the clothes industry, most of the fabrics, especially natural fabrics, are prone to mold. Base... | |

| Anti-mold Desiccant | Seller: KOBSO (CHINA) LIMITED | Anti-mold desiccants are materials used to absorb moisture and prevent mold growth in products an... | |

| Activated Carbon Desiccant | Seller: KOBSO (CHINA) LIMITED | Activated Carbon Desiccant The role of activated carbon depends on its own adsorption function, w... |