Non-standard Parts

Standard parts are parts produced in accordance with national standards (GB), industry standards, or foreign standards, mainly for the convenience of maintenance and replacement, such as screws, keys, flanges, bearings, etc. are standard parts, which can be bought directly from the market when designing the required parts, without the need for special separate production, reducing costs and improving labor efficiency. Non standard partsare those parts that cannot be bought directly from the market and must be customized by contacting special manufacturers. Of course, the cost is higher, and some parts do not have a unified standard, and can not form a standard, such as gears, and pulleys. Must be processed separately.

Non-standard Parts of Different Materials

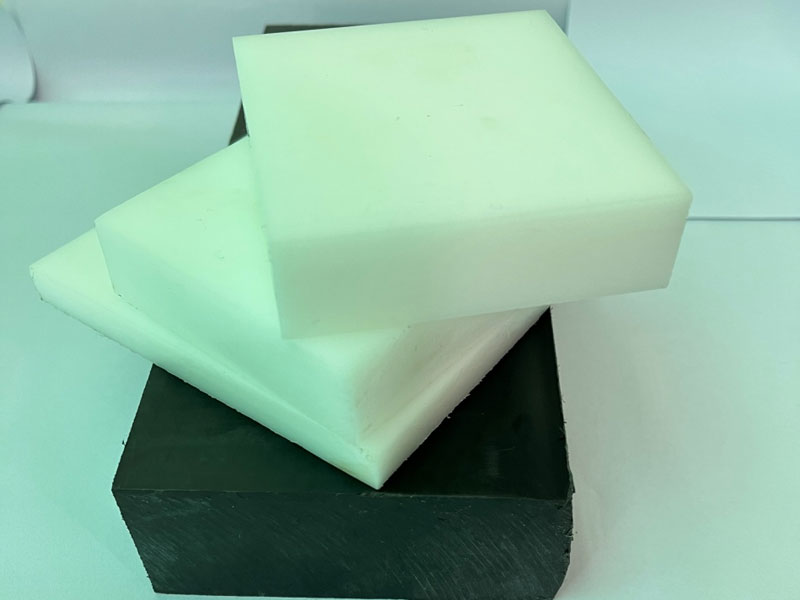

Nylon Non-standard Parts

Nylon often takes the place of brass, aluminum, steel, bronze and several other metals as well as several plastics, rubber and wood. It is also one of the most popular polymers used for industrial applications, as they can be processed precisely to the tightest specifications. It is a relatively low cost plastic that is well suited for parts requiring high tensile strength.

POM Non-standard Parts

POM is a popular choice for easy machining for CNC operations. It exhibits good mechanical performance, self-lubrication, good machining properties and good dimensional stability. Acetal or POM is a very common and widely used engineering plastic. As such, POM plastics are very similar to high performance plastics. This material does not require additional pretreatments during machining. Carbide drills are used and should always be kept sharp. This thermoplastic has a wide range of applications in industry.

PEEK Non-standard Parts

PEEK ( polyether ether ketone ) is a high-performance engineering plastic with resistance to harsh chemicals, as well as mechanical strength and dimensional stability. It is resistant to hydrolysis of steam, seawater and water, and PEEK has the ability to maintain hardness at elevated temperatures. This engineering plastic has a proven track record in challenging environments such as aerospace, food and beverage processing, and semiconductors.

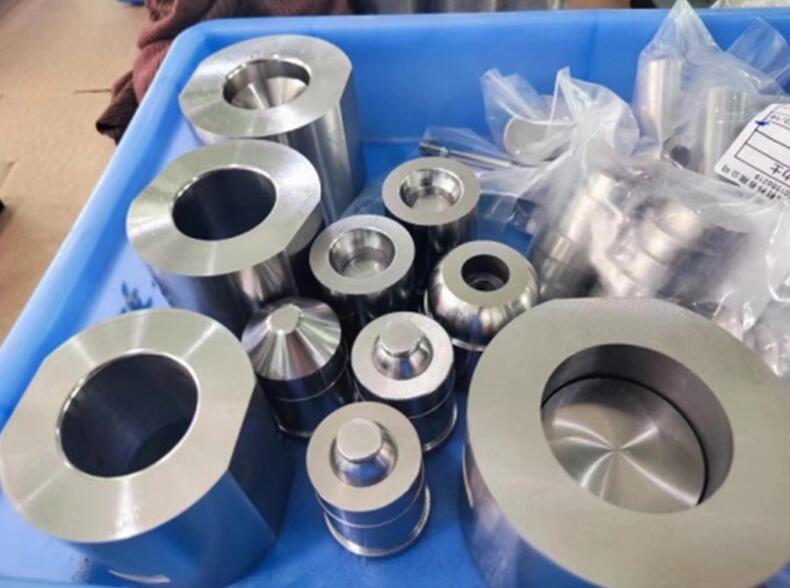

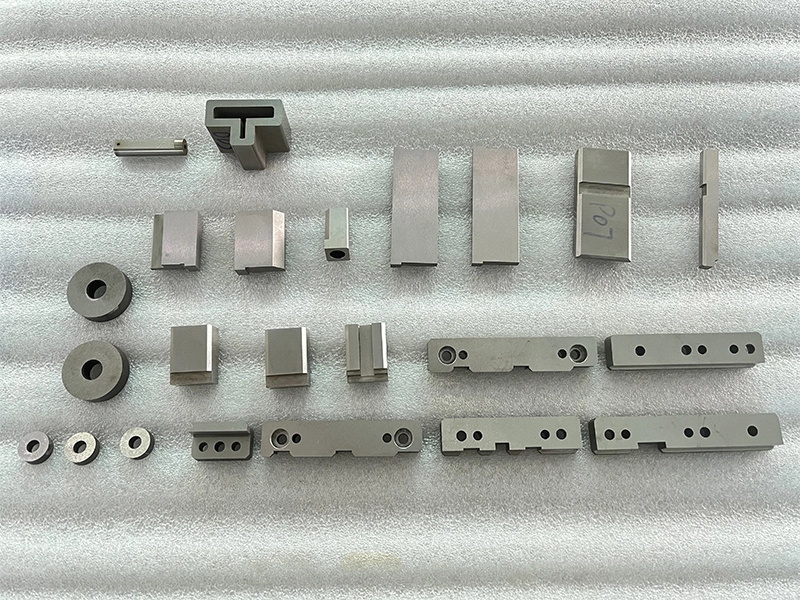

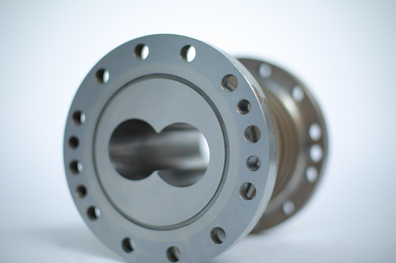

Steel Non-standard Parts

The processing of precision parts is roughly divided into two categories: standard parts processing and non-standard parts processing. Relatively speaking, the processing of non-standard parts is more difficult than the processing of standard parts. Hui Huan Machining has rich experience in non-standard precision machining, and all of our products are customized according to your drawings. We specialize in CNC precision machining for milling, EDM, WEDM and grinding processes, and can also provide fixturing and part assembly services. A wide selection of materials and strict quality control to meet your requirements.

Brass Non-standard Parts

Hui Huan Machining has rich experience in non-standard precision machining, and all of our products are customized according to your drawings. We specialize in CNC precision quality machiningfor milling, EDM, WEDM and grinding processes, and can also provide fixturing and part assembly services.

Aluminum Non-standard Parts

Aluminum material has the advantages of light weight and softness, good strength, good processing performance, good corrosion resistance, etc. For CNC processing of non-standard parts should choose high-speed steel tools and special aluminum tools. Choose high speed, high feed processing method.

The Impact of Non-Standard Parts on Manufacturing

Non-standard parts can have a significant impact on the manufacturing process, as they often require additional time, money, and resources to produce. They can also cause delays in production and increase costs due to the need for additional tools or machinery to create the parts. Additionally, they can create compatibility issues with other parts, leading to potential quality control issues. Finally, integrating non-standard parts into the manufacturing process can require additional training for staff to ensure that the parts are being used correctly and safely.

The Benefits of Standardizing Non-Standard Parts

Standardizing non-standard parts has many benefits for both manufacturers and customers. Standardizing parts reduces confusion and helps customers and manufacturers alike to quickly identify and replace parts. Additionally, it can reduce costs for manufacturers by eliminating the need to manufacture parts that are not cost-effective to produce. This, in turn, can result in lower prices for customers. Moreover, standardizing parts can reduce the number of errors in manufacturing, since parts that are not standard can be difficult to identify and replace. Finally, standardizing parts can speed up the manufacturing process, since there is no need to search for, or manufacture, non-standard parts.

As a precision machining manufacturer, we will do our best to meet all the needs of customers.

Send product request

Other supplier products

| Carbide Mold Components | Carbide Components We are very capable of customizing punches and dies to produce precision tungsten punches, bushings, ejectors, and die componen... | |

| CNC Machining Material | Metal Material Machining Aluminum Alloys Aluminum alloy material is divided into: 6061 mainly contains magnesium and silicon elements, suitable... | |

| Copper Precision Spare Parts | Copper Precision Spare Parts T1, T2 copper is mainly used as conductive, heat-conducting and corrosion-resistant components, such as wires, cables,... | |

| Metal CNC Machining Parts | cnc metal parts factory/ cnc machining metal parts factory custom cnc metal parts/ cnc machined metal parts/ metal cnc machined parts/ metal cnc p... | |

| EDM Spark | Electrical Discharge Machining ServicesSpark During the EDM process, an electric current crosses the gap between the electrode and the workpiece (... |

Same products

| Corn Peptide Manufacturer | Seller: Shandong Bigtree Dreyfus Special Mealsfood Co., Ltd. | Corn Peptide Manufacturer Bigtree corn peptideproduct is a naturally-sourced, high-quality dieta... | |

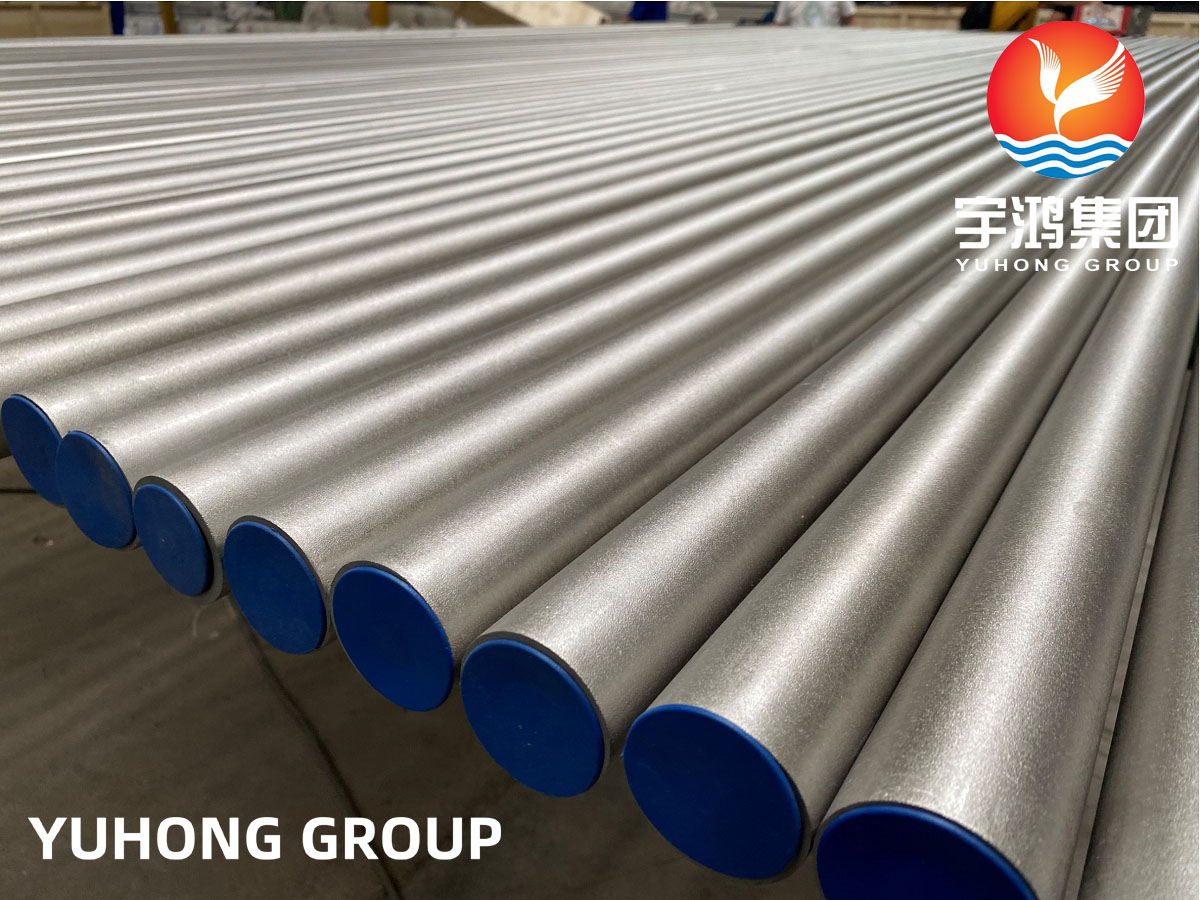

| ASTM A312/ASME SA312 STAINLESS STEEL PIPE | Seller: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | ASTM A312/ASME SA312stainless steel pipe covers seamless straight seams welding and heavy cold wo... | |

| NICKEL ALLOY STEEL PIPE /TUBE | Seller: YUHONG GROUP CO., LIMITED ZHEJIANG YUHONGWELL STEEL CO., LIMITED | Nickel alloy is one of the most useful materials for manufacturing technically superior nickel pi... | |

| Non-standard Parts | Seller: SHEN ZHEN HUIHUAN TECHNOLOGY CO,.LTD | Standard parts are parts produced in accordance with national standards (GB), industry standards,... | |

| Barrels | Seller: Nanjing KY Chemical Machinery Co., Ltd. | The body of the basic grade barrel is made of 45 # steel. The liner of the barrel is made of basi... |