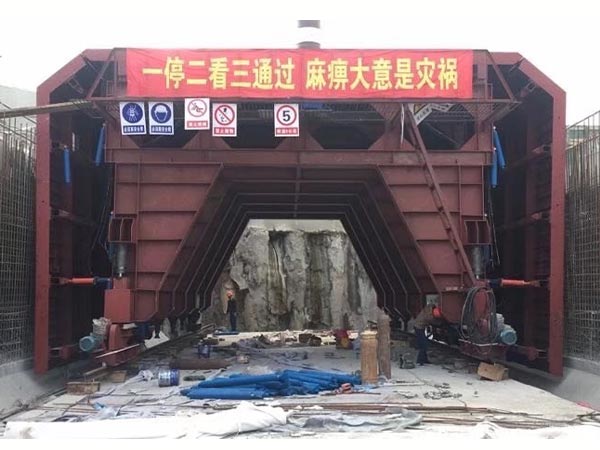

Tunnel formwork bypass channel

The tunnel formwork channel is a non-standard product specially designed and manufactured for the concrete lining of water tunnels such as tunnels and culverts. It has the functions of vertical mold and demoulding function, high surface finish of lining and fast lining speed. The working process of the steel formwork trolley is carried out in the following steps:

FIRST, CHECK WHETHER THE TUNNEL CONSTRUCTION CONDITIONS MEET THE DESIGN REQUIREMENTS OF THE TEMPLATE TROLLEY:

Since the formwork trolley is a non-standard equipment, the conditions of use must meet the design requirements before lining.

Check whether the road surface elevation and road surface condition meet the design requirements, the road surface elevation: as shown in the figure; the road surface condition: concrete road surface;

Check whether the sleepers and rails meet the design requirements;

Check whether the outer surface of the steel formwork is coated with a release agent.

Click to visit:

Send product request

Other supplier products

| PIPELINE MUNICIPAL LINING TROLLEY | PIPELINE MUNICIPAL LINING TROLLEY ADVANTAGES 1.SHORT CONSTRUCTION PERIOD Compared with the traditional bakelite formwork and the aluminum al... | |

| hydraulic system | The lining trolley hydraulic system is the power source for the trolley to complete the vertical mold and demoulding work. Except for the trolley t... | |

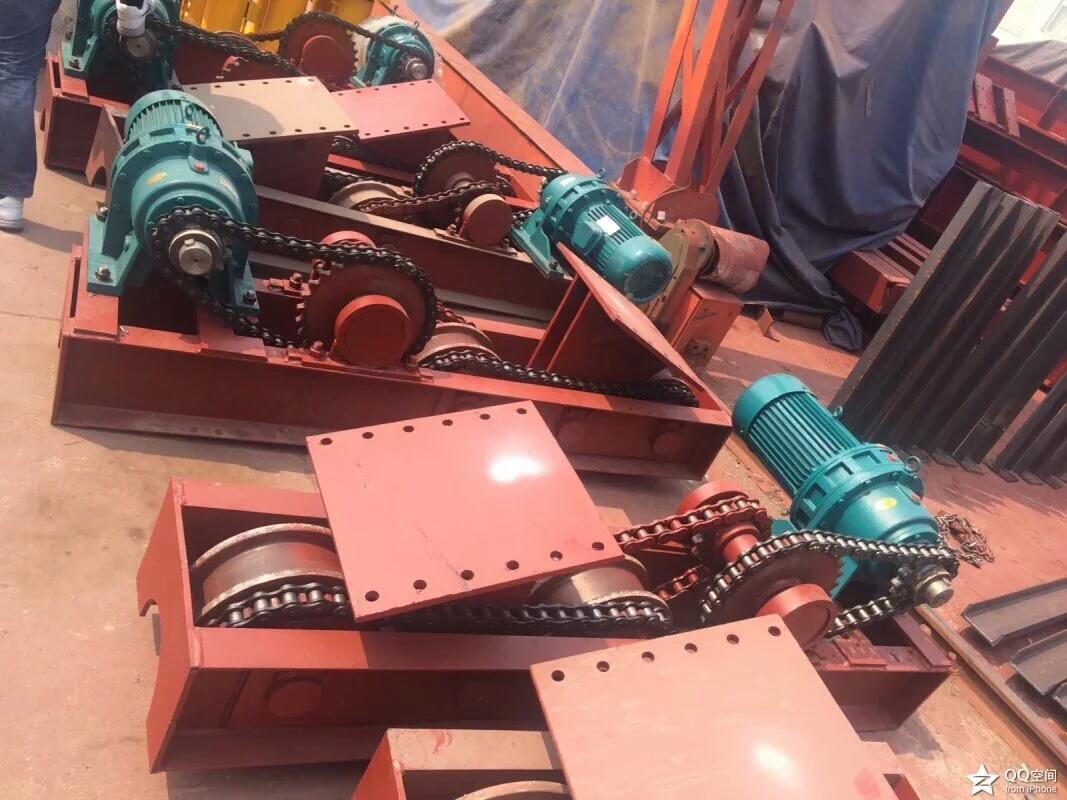

| walking-system | Lining trolley walking system and steel formwork trolleys after the demoulding, first close the gantry support jack, then tighten the gantry to sup... | |

| Single-track railway lining trolley | Single-track railway lining trolley is a special equipment that must be used in the secondary lining of single-track railway tunnel construction. I... | |

| Tunnel formwork bypass channel | The tunnel formwork channel is a non-standard product specially designed and manufactured for the concrete lining of water tunnels such as tunnels ... |