Precision Mould

How to build a plastic precision hanking mould?

HanKing Mould Enginering Ltd.hasbeen manufacturing plastic precision moulds for more than ten years. With hanking’s expertise and experiencen of hanking mould technology, we provide valuable mold opening suggestions to our customers according to their specific needs, thus helping customers save manpower and resources.

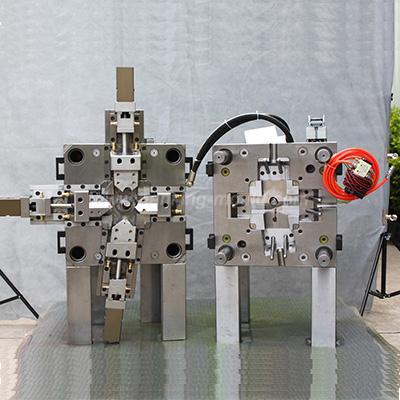

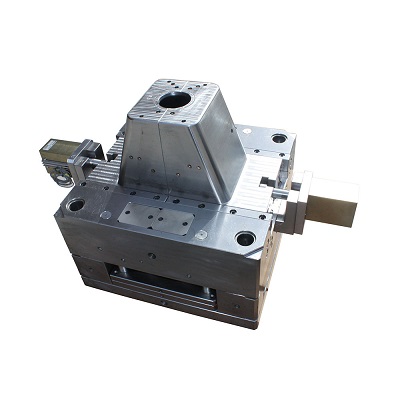

Plastic precision mould toolsare normally required to be short mold cycle time and long life cycle, a good tool maker should find the best mould solution combine the specific needs of customers, the mould must be easy handling and maintenance.

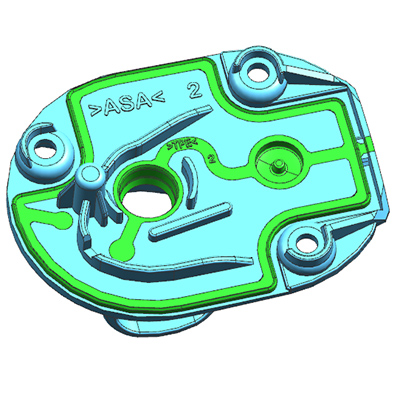

In order to ensure the smooth progress of the precision hanking mouldingproject, detailed mould design analysis(DFM) must be done, and if necessary, mold flow analysis is required.

Before starting the processing, we need to communicate with the clients repeatedly, fully understand the needs of the customers, design the molds that meet the production requirements. DFM, mold design must be confirmed by customers before starting to manufacture the moulds.

Stable employees are also very important. We have a comfortable working environment: central air conditioning, dehumidification system, exhaust system and epoxy floor. Our employees and technicians have been working here for many years and this is an important factor in ensuring quality stability.

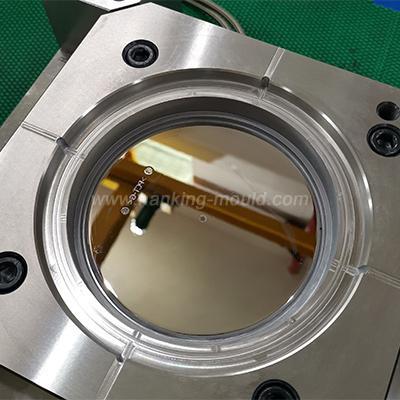

Precision mould trial: With special mold trial injection molding machine, qualified mold trial operator to ensure professional and on-time sampling service for customers.

In HanKing Mold, hankingtechave a complete set of high-precision measurement equipment, capable of providing full dimension FAI measurement reports.

Weekly work schedule, mould pictures, and test report will be sent to the customers.

With reliable quality, on-time delivery and reasonable price, not only provide professional one-stop service from plastic precision mould development, but also flexible service to individual molds or small batch plastic parts production. Whether the order is big or low volume, shenzhen hankingwill make the bestinjection mold made in china, all customers are VIP.

Send product request

Other supplier products

| Multi Cavity Mould | 24 Cavities Plastic Injection Mold Product Name: 24 Cavities Plastic Injection MoldMold Base: LKM, HASCO, DME, etc.Mold Steel: NAK80, ASSAB8407, S1... | |

| Over-Molding Parts | Custom Mold & Design The overmolded partsis a process that can bond different materials by the injection moulding. Plastic injection ove... | |

| Precision Mould | How to build a high precision mould? We have been manufacturing plastic precision moulds for more than ten years. With our expertise and experien... | |

| Home Appliance Mould | HanKing Mould Enginering Ltd.offer various products to meet people’s needs, including home appliance mold. Embroidery Machine Frame Mould Pl... | |

| Industrial Mould | Plastic Mould Tool Making We have the tool making capacity for precision injection mold projects, with high precision CNC machining and EDM, slow w... |

Same products

| Enhanced Water-Cooled Paddle Wheel Aerator | Seller: Taizhou Yuansheng Aquacul Ture Machinery Co., Ltd. | The Enhanced Water-Cooled Paddle Wheel Aeratoris engineered for steady, long-term use in medium t... | |

| Honeywell BW MicroClip Series XT-XWHM-Y-CN | Seller: CW Green Tech | Honeywell BW MicroClip Series XT-XWHM-Y-CN The industrial Honeywell BW™ MicroClip Series i... | |

| High-Efficiency Sludge Dewatering Machine for Wastewater | Seller: Apoaqua | The sludge dewatering machine produced by Apoaqua follows the principles of force and water in th... | |

| Climate And Vibration Combined Test | Seller: Guangdong Yuanyao Test Equipment Co.,Ltd. | Model: YTHV-216 YTHV-343 YTHV-512 YTHV-720 YTHV-1000 Main Parameters: Temperature: 0℃/-20℃/... | |

| High Temperature Clean Drying Oven | Seller: Guangdong Yuanyao Test Equipment Co.,Ltd. | Model: YCO-072 YCO-270 YCO-480 YCO-600 YCO-720 YCO-1000 Main Parameters: Dustproof class: C... |